[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 42, no. 20, p. 377-385, col. 1-3

Recent Development of the Central-station

Industry in Chicago.

MARKING the beginning of the third decade of central-station activity in Chicago, the year 1908 is not without a special significance. In 1887 the Chicago Edison Company was organized, and this was the first company in Chicago and practically in the West to engage in the regular business of selling electricity for various kinds of lighting and power service. From those. days of infancy the industry has steadily grown with giant strides to its enormous size today.

This growth has been made possible by the rapid and harmonious development of the administrative and engineering branches of the business. On the one hand there has been the adaptation of high-tension transmission which has permitted the concentration of the generating power into a small number of large, highly developed and economical generating plants. On the other hand there has been the consolidation of a large number of small and more or less competitive companies into a single, large, economically administered corporation, the Commonwealth Edison Company.

|

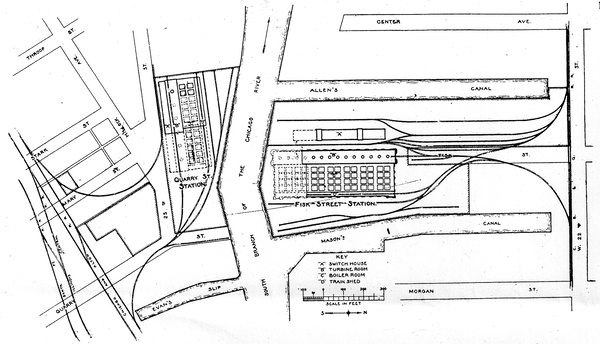

| Plat of Fisk Street and Quarry Street Properties of Commonwealth Edison Company. |

This company operates within the city limits of Chicago. Working in harmony with it is the North Shore Electric Company, operating in the suburban territory outside the city limits and supplying electrical energy to over 30 villages, towns and cities in the crescent-shaped zone around Chicago. This great belt supplied by those two friendly companies extends along the curving shore of Lake Michigan from the Indiana state line to a point between 60 and 70 miles northward, north of Waukegan, Ill. In the neighborhood of Elmhurst, Ill., this belt attains its greatest width of about 18 miles. These figures bear out the belief that this is the largest interconnected system operating from steam-driven generating plants in the world.

The result of these centralizing tendencies has been an enormous extension of the business accompanied by relatively reduced fixed charges on the investment in stations as well as transmission and distribution systems and reduced operating expenses. All these factors combined have permitted a steady reduction of rates to the consumers which has brought further increases in business. On the whole the growth of these two allied companies is one of the best examples of the public benefits that may accrue from the centralized control of a great public utility.

The evolution of the industry in Chicago has occurred in certain well-defined stages, the most striking of which is doubtless that of the last five years. On May 23, 1903 (coincident, with the last Chicago convention of the National Electric Light Association), there appeared an elaborate article in the Western Electrician on the- developments in central-station engineering in Chicago to that time. The purpose of the present article will be mainly to review the developments along this and allied lines since that time.

GENERATING STATIONS.

The Commonwealth Edison Company now has in active service two principal generating stations, the older one at Harrison Street, now operated as such only about half of each day, and the large station at Fisk Street, which for several years has been the pride of the system. A new station is being built at Quarry Street on the opposite side of the river from the Fisk Street station. At the Fifty-sixth Street, Market Street and North Clark Street sub-stations, which were formerly among the generating stations, a number of steam-driven generating units are held as reserve and are operated in emergencies to help out the winter peak load.

HARRISON STREET STATION.

In the year 1903 the station on the west bank of the river at Harrison Street was the principal generating station of the system. There had been installed a total of 25 generators, comprising three different types. Of these there were eight 200-kilowatt and twelve 400-kilowatt direct-current machines operating in pairs on the Edison three-wire system. Most of these machines had been in continuous service for nearly to years. Two pairs of these units had been changed to double-current generators, developing three-phase, 25-cycle current at 85 volts on the alternating-current side. This was stepped up to 9,000 volts for transmission to substations. Of the five large generators one was a 2,500-kilowatt double-current unit, developing twice the voltage of the similar small machines. The remaining four units were three-phase, 25-cycle machines, generating 9,000 volts, their sizes were two units of 1,000 kilowatts each, one of 1,800 and one of 3,500 kilowatts. The total rated capacity of the station thus aggregated 16,200 kilowatts. All the engines were vertical triple-expansion or compound engines.

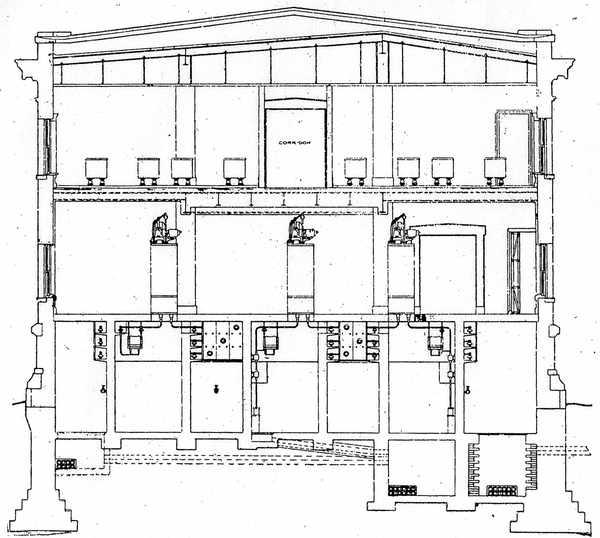

|

| Cross-Section of Switch House, Fisk Street Station. |

Since this period two engine units, comprising two pairs of zoo-kilowatt three-wire generators, have been removed, one of the 1,000-kilowatt alternating-current generators is being removed and the other one will be before long ; the two latter machines had been driven by a rope drive, and the entire set took up considerable room. The double-current generators have been disconnected from the engine-connecting rods and are now being run as rotary converters. A 2,000-kilowatt rotary has also been installed.

The generating plant is now being run from about 7 a. m. to about 9 p. m. daily and shut down at night. While running the plant is operated at practically constant full load, thus working each machine at its point of maximum efficiency and therefore yielding the highest station efficiency. The rotary converters are in continuous operation and convert current from Fisk Street for local direct-current distribution. On account of its nearness to the center of the load and its railroad and water facilities this station will probably be operated in this way for some time to come. Steam turbines may replace its reciprocating engines and thus enlarge its capacity.

|

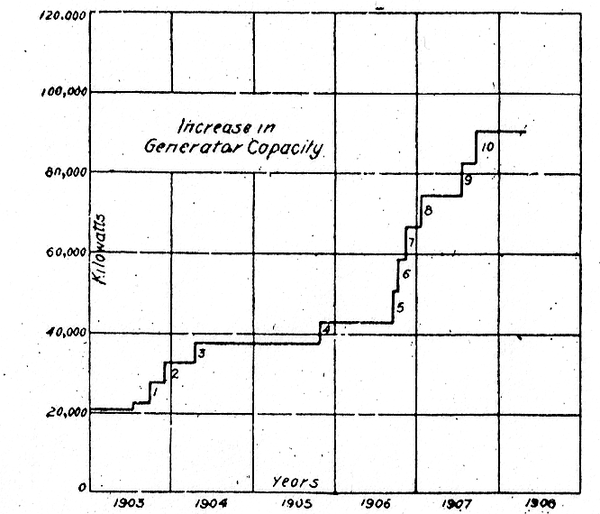

| Increase in Central-Station Rated Generating Capacity in Chicago. |

In its 14 years of operation this station has passed through many stages of the development of electrical generating machinery. Keeping pace with the times, the most noteworthy changes have been the gradual elimination of the small and bulky units; installation of rotary converters to help feed the low-tension, three-wire distributing network during the day and carry all its load at night; and the installation of three-phase 9,000-volt generators to supply sub-stations in the business district during their periods of heavy load. It should be noted that since 1897 there has been practically no increase in the direct generation of 250/125-volt direct current in either this or any other station. All additional increase in the low-tension system has been supplied by rotary converters taking alternating current transmitted to them at 9,000 volts.

As the economy and reliability of, this transmission was demonstrated by the operation of the 9,000-volt machines at Harrison Street, and as the load on the entire system was growing so rapidly that possible enlargements of this station's capacity could not supply the increase for more than a few years, it was decided to build a new station on a tract of comparatively low-priced land some 2 ½ miles further from the business center. The site chosen was at Fisk Street, between Twenty-second Street and the river, where excellent railroad and water facilities were available and where there was considerable room to expand.

FISK STREET STATION.

The construction of this justly called historic central station was begun in Icon. Its design had been carefully considered by the company's engineers, and the apparently radical decision to use vertical-shaft steam turbines of 5,000-kilowatt capacity had back of it enough confidence in their reliability to warrant their use for the first time. In view of the fact that practically no Curtis turbines had been built tip to that time, excepting some run in the shops, the installation of these large vertical machines was watched with interest by engineers all over the world. That the confidence in their reliability was justified has been amply borne out by the service these machines have rendered. Their performance has been studied in great detail and has enabled the General Electric Company, who manufactured them, to so improve on their design that the latest units installed arc nearly twice as efficient as the pioneer 5,000-kilowatt unit.

Thus the Fisk Street station occupies a unique place in the recent rapid development of the steam turbine. It was not only the first great central station to be equipped exclusively with steam turbo-generators of large capacity, but here in a few years the steam turbine has achieved such satisfactory results as to secure its installation in most of the large modern power plants, where efficiency and reliability of operation as well as economy of floor space are important.

General Design.

The general features of the design and construction of this station have keen described in many articles from time to time in this and other journals. Particular attention should be called to two long and well-illustrated articles in the Western Electrician of May 23 1903, and January 6, 1906; the first article was the first extended description of the plant to appear in the technical press; the latter article contained detailed plans and elevations of the station as then completed with four units installed. It will be necessary here, therefore, to mention only such essential points as will make clear the improvements in the new sections that have taken place during the growth of the plant.

|

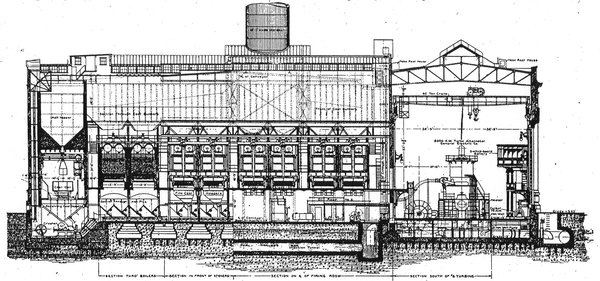

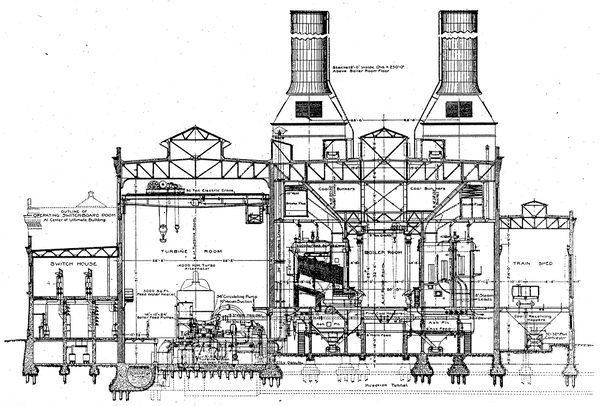

| Cross-Section of Fisk Street Station. |

The original design of the station provided for the ultimate installation of 14 Curtis turbo-generators rated at 5,000 kilowatts each, thus giving a total station output of 70,000 kilowatts at full load. It was found, however, that the turbines were capable of carrying enormous overloads and that the capacity of the generators, due to dangerous heating on these overloads, really limited the output attainable from the turbines. Moreover, the efficiency of the first units was actually better on overload than at rated full load. This led to the installation of larger generators on the turbines put in after No. 4. This fact, added to improvements in the design of the turbines, has given the last six units a manufacturer's rating of 8,000 kilowatts each, although the turbines themselves are not much larger than the first four. Thus, with the so units now in, the rated load of the station has reached 68,000 kilowatts, or practically as much as was originally contemplated for 14 units:

Growth of the Plant.

A diagram is given showing the increase in generating capacity of the system based on the manufacturer's rating for the generators in the three small reserve stations and the main stations at Harrison and Fisk streets. The most interesting portion of the diagram is that from October, 1903, to the present. The figures 1 to 10 opposite these increments represent the units added at Fisk Street. Hence the diagram shows very forcibly the rapid growth of the Fisk Street station and its relation to the system as a whole, as well as the exact date each new unit was put on commercial load.

Turbo-generators.

As related above, the turbines are capable of great overloads, in most units as high as 50 per cent., and in one instance of 75 per cent. Continuously. This has resulted in various statements of the total capacity of the station, which is now frequently placed at 100,000 kilowatts or more; in other words, about 50 per cent. Above the nominal rating. This high figure is doubtless near the maximum output of the station at peak load. The generators were designed for continuous operation at their rated load and the increased capacity of the turbines for continuous running above this load was one of the surprises developed in their performance.

To increase the amount of overload these large generators can carry without dangerous heating of their windings, various experiments have been carried on to provide induced or forced-draft ventilation. When it is considered that in an 8,000-kilowatt generator about 400 kilowatts is normally converted into heat from the unavoidable energy losses in the machine and that this vast heat must be dissipated, the importance of ventilation is evident. Mounting the generator directly over the turbine makes the problem more complicated. A fan-like construction of the rotating field has been used to induce a downward draft through the machine.

| |||

| Here is A Row of Ten Turbo-Generators Having A Total Maximum Capacity of 100,000 Kilowatts. |

The speed of the last six units is 750 revolutions per minute instead of 500 in the first four. To get the same frequency, 25 cycles per second, the revolving fields of the newer generators have only four poles instead of six on the earlier machines. On account of their higher speed, the new generators are really not much larger in bulk, though their output is 60 per cent greater than that of the first four generators. The diameter of the revolving fields of the 5,000-kilowatt machines is about seven feet four inches, whereas that of the 8,000-kilowatt machines is six feet three inches. The revolving fields of the new units are of the smooth rotor type instead of having definite poles. Considering their capacity, these generators are extremely compact.

The turbine units Nos. 2 and 3 are two-stage machines with three steam chests, each containing 12 nozzles. Unit No. 4 was built as a four-stage machine with only two steam chests, each having 15 nozzles. The last six units were built with five stages. The governing mechanism on these turbines is different from that used on the first four. The earlier machines had electrical control, a solenoid being connected with each valve. To get a more positive action of the valves the newer turbines are provided with hydraulic control.

Condensers.

Structurally the newer units differ from the first four by having sub-base condensers, i. e., the turbines are mounted directly over the condensers instead of having the latter placed alongside of the turbine. The new condensers have 25,000 square feet of condensing surface as compared with 20,000 in the older units. This construction has been found to possess certain marked, advantages, the two most important being, first, much more direct Connection with the turbine exhaust, and consequently a higher vacuum and better efficiency (comparative tests of units Nos. 1, 4 and 8 showing vacua of 28.52, 28.30 and 29.50 inches, respectively, as related to 30 inches barometric pressure); second, further economy of floor space, tile height of the entire unit being raised somewhat to compensate for this.

Performance of the Turbines.

Extensive tests have been made on all these units from time to time. Some of the results as to heating and vacua have been alluded to already. In a paper by Prof. J. C. Thorpe of the University of Illinois on "Steam Turbine Development," read before the Western Society of Engineers on May 6th and abstracted on another page of this issue, some interesting performance data and curves obtained on turbine units Nos. 1, 4 and 8 are given. These machines were run on a steam consumption of 23.94, 16.72 and 13.07 pounds per kilowatt-hour, respectively. This shows a wonderful improvement in inefficiency of these turbines inside of three years. The last figure places this steam turbine in the front rank among prime movers. Another feature brought out was the flatness of the economy curve for a large range of load. Maximum steam economy was obtained at loads varying from 115 to 130 per cent, of the rated capacity of the machines, and it was practically the same to over 150 per. cent, of the manufacturer's rated load.

New System of Rating.

As the result of those determinations it has been decided by the General Electric Company to adopt a new system of rating its turbines. Instead of using as a basis a certain value, as the normal load and giving certain guarantees of overload operation for limited periods, the rating will represent the continuous maximum operating capacity of the unit. No overloads beyond this continuous maximum will be provided for. The generators for future turbines will be of such a size as to permit of continuous running at this maximum without dangerous heating. The turbo-generators of the new Quarry Street station will be rated in this manner.

Other Features.

In the boiler-room practice at the Fisk Street station no very radical changes are at first apparent. However, it is to be noted that the same rated capacity of boilers was installed for the first unit of 5,000 kilowatts as for the last one of 8,000 kilowatts, which is largely accounted for by the better steam economy of the latter. The boiler equipments for the last six units are also giving a better evaporative performance. The last three stacks corresponding to the last six units have a height of 26o feet instead of 205 feet for the first two stacks.

The exciter sets at first comprise three 50-kilowatt exciters direct driven by induction motors and one 75-kilowatt exciter driven by a vertical Corliss engine. For the later units there have been added a 75 and a 150-kilowatt motor-driven exciter and two 75-kilowatt turbine-driven exciters. Two additional storage batteries for floating on the exciter bus-bars have been installed on the second floor of the switch house. The original battery placed over the north end of the boiler house is still in service. The three batteries insure absolute continuity of exciting current.

An important feature of the operation of the Fisk Street station has been carried out within the last year. It is its operation in two distinct sections. The unit system so extensively carried out in all parts of the station permits the running of each turbo-generator independently in every respect, and this is made use of in testing. However, when connected to the system load sectionalizing is not carried out in such great detail, as this is unnecessary for all normal requirements of the system. Nevertheless, the advantages of sectionalizing in isolating any possible troubles are so great that it is now the rule to run the entire system in two sections instead of entirely in parallel. The first four units are connected to one section and the last four to the other, the two intermediate units being arranged so they can help out either section.

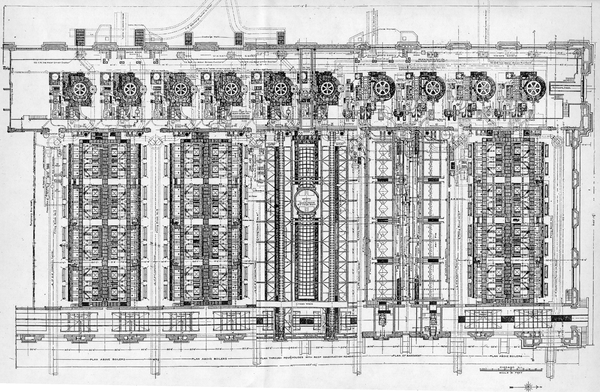

There are so many interesting features about the Fish Street station that it is impossible in a limited article to more than ouch on a few of the most important. The general layout has not been described, as it is made clear by the accompanying plan and cross-sectional-elevation drawings. These with the exterior and interior views give a better idea of its size and architectural beauty than can be conveyed by a multitude of words. Thousands of visitors from all parts of the world have become convinced that it is one of the largest, finest and most unique power plants in existence.

|

| General Plan of Fisk Street Station of Commonwealth Edison Company, Chicago, With Ten Units. |

|

| Cross-Sectional Elevation. |

|

| Quarry Street Station Now Building for the Commonwealth Edison Company. |

QUARRY STREET STATION.

The rapid growth of load on the entire system in the last few years showed that before many more years the Fisk Street station would be taxed to its utmost capacity, even with the addition of the four more units contemplated in the ultimate plans. It was deemed advisable to plan and proceed with the erection of another station before its need became imperative. By thus anticipating the future requirements, the system would not only be better prepared for any abnormal increase of load but would have a larger factor of safety in reliability of service by not concentrating almost all its generating capacity in a single station. Property on the other side of the river from the Fisk Street station being available, it was decided to build the new station there and obtain all the advantages in the way of water and railroad facilities and near ness to the center of load possessed by the Fisk Street plant.

|

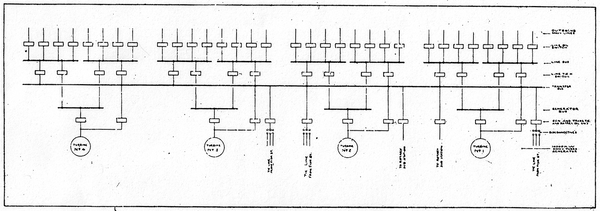

| 9,000-Volt Connections Quarry Street Station. |

|

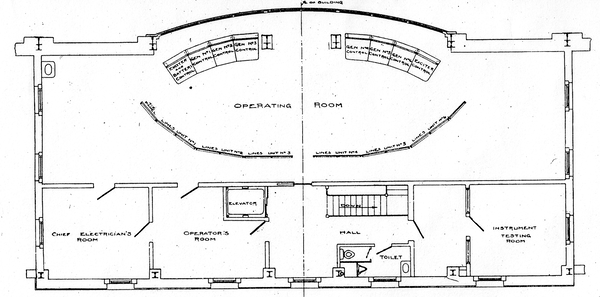

| Plan of Third Floor of Switch House, Quarry Street Station. |

General Design.

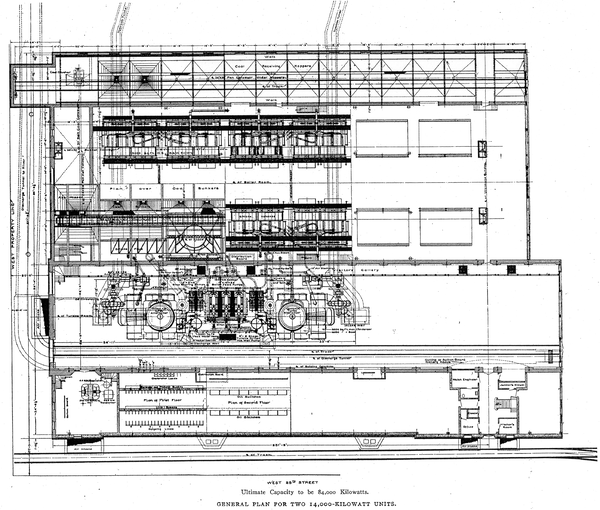

A study of the plat of the properties of the company in this neighborhood shows that the land on the south side of the river chosen as the new site was much narrower than the Fisk Street site. This had a decided influence on the design of the station and accounts for many of its features that differ from its near-by prototype. It is evident from a comparative glance at the plans that the Quarry Street station, first mention of which in the technical press was in the Western Electrician of January 4, 1908, will be relatively long and narrows The switch house is joined to the main building, and the boiler room runs longitudinally parallel with the turbine room instead of being in sections at right angles thereto.

The station building is designed for an ultimate size of about 463 by 208 feet and a total equipment of six turbo-generating units of 14,000 kilowatts each. At the present time a little more than the west half of the building is being erected, and this year only the first unit will be installed. This is at the west end of the building, so that the addition of subsequent units can go on without interfering with the service of the completed machines. When fully completed the maximum capacity of the station will be 84,000 kilowatts for continuous operation, or approximately equal to the present capacity of Fisk Street station under a similar rating. According to the present plan the new Quarry Street station will be entirely equipped before the four additional units contemplated at Fisk Street will be added.

The completed building will occupy over one-half the available ground space, the remainder being used for coal storage. Another plat of ground south of Twenty-fifth Street, owned by the company, will be similarly utilized.

The four main sections of the building—switch house, turbine room, boiler room and train shed—are separated by heavy fire walls. The boiler and turbine rooms have roof trusses at the same level, which is 61 feet clear above the floor in the turbine room. Architecturally the station will not be a replica of Fisk Street, though it will harmonize with it. The ornamentation will be along simpler yet tasteful lines. The architects for the building were Shepley, Rutan & Coolidge, while Sargent & Lundy are the consulting mechanical engineers.

Coal Handling.

Coal trains will enter the train shed over a trestle east of the building. The train shed has a series of hoppers below its track, into which bottom-dump cars discharge directly. Ordinary gondola cars will be taken care of by a coal unloader having a grab bucket that takes up about a ton of coal and dumps into the extended hopper alongside the car. These hoppers discharge into a 32-inch pan conveyor, which dumps the coal into a crusher. From this it drops on a belt cross-conveyor, which supplies the two main bucket conveyors passing over the coal bunkers situated above each row of boilers.

Ashes are handled by these same bucket conveyors and dumped into an ash hopper at the end of each row of coal bunkers. From these hoppers the ashes are dropped into a special ash conveyor that dumps into empty cars at the end of the train-shed track.

Boiler Room.

The boiler room has a width of 83 feet 8 inches and a present length of 231 feet. Its floor is 12 feet above that of the turbine room, which gives it an exceptionally high basement 18 feet below the main-floor level. The boilers are arranged in two opposite rows in batteries of two. Each turbine unit has its steam supplied by a set of eight boilers.

The boilers are of the Babcock & Wilcox water-tube type and have a total of 5,087 square feet of heating surface each. There are in each boiler two steam and water drums 42 inches in diameter and 20 feet 7 1/2 inches long connected to 18 sections of water tubes composed of 18 tubes per section, the tubes having a diameter of four inches and length of 18 feet. The boilers have an evaporative capacity of over six pounds of water per square foot of heating surface and are guaranteed to develop 35,000 pounds of steam per hour at 225 pounds gauge pressure and 130° F. superheat.

Each boiler has a Babcock & Wilcox chain-grate stoker with 102 by 138 inches of grate surface. A new method of firing the boilers will be used. Instead of firing at the high end of the tubes, the reverse plan will be tried and the boiler in effect turned around. By firing from the low end a larger combustion chamber will be provided and more efficient combustion is anticipated.

A steel stack 12 feet inside diameter and 250 feet high above the boiler-room floor will be erected over every second battery so as to take up the gases from six boilers. Two stacks will be erected at present, the completed station having eight. The stacks, coal bunkers and roof trusses are each supported on a separate set of columns and independent structural work. Between the opposite coal bunkers a clear space is left for a flood of daylight from above to the firing floor. This space is to be spanned by a five-ton hand-operated traveling crane. The six-inch steam header from each boiler is carried to the space between two batteries and passes down to the header gallery in the basement, where a 12-inch header connects the two batteries with the turbine room.

Turbine Room.

The present length of the turbine room is 268 feet 8 inches and its width 56 feet 4 inches. The basement under it is at the city datum level, and the turbine-room floor is so feet above this. Spanning the main room will be, an electric crane of go tons capacity. A railroad track will be permanently laid along the south side of the room to facilitate the rapid unloading of machinery.

The main generating units are Curtis turbo-generators, designed in accordance with the new rating referred to above for a continuous maximum operating capacity of 14,coo kilowatts. They will be installed right and left alternately at a distance of 67 feet center to center on the side where the circulating pumps are located and 70 feet center to center on the side where the other auxiliaries arc placed. This arrangement is slightly different from that at Fisk Street, as can be seen from the accompanying plans, but it is believed it will permit greater economy of floor space and aid in the supervision of the machinery.

The turbines are to be only a little larger than the later units at Fisk Street. The generators, however, will be much larger so as to be able to carry 14,000 kilowatts continuously. Forced ventilation, as already alluded to, will be employed to keep the generators running cool. Air will be drawn in through air intakes from outside the building at about the basement level and passed through large ducts in the cool portion of the basement that will come up alongside the turbine and deliver the air to the top of the generator, which will be entirely enclosed. Here specially constructed fan blades on the revolving field will drive the air down through the windings of the machine. An auxiliary blower may be provided in the basement to furnish additional draft if necessary. It is believed this system of ventilation will be ample.

Condenser Equipment.

Condensers for the turbines will be of the sub-base type and built in three sections as those at Fisk Street. The condensers will be entirely in the basement below the turbine room, however, so that the turbines will come, level with the floor. Two sections of the condenser of 8,000 square feet condensing surface will be directly below the turbine proper, and the third or auxiliary section of 9,000 square feet will adjoin the others. An injection tunnel supplies water from the river to the intake well for two units. The first unit will have a separate tunnel of half the cross-section of the others. A 36-inch centrifugal circulating pump draws the water from this cold well, forces it through the condenser and then discharges it into a common discharge tunnel of about so feet diameter along the south wall of the basement, and this discharges into the river west of the building. The injection tunnels are provided with cribs arid screens at the river similar to those at the Fisk Street station.

The circulating pump referred to is mounted directly on the shaft of a 20 by 24-inch simple Corliss engine, which also operates a 28 by 24-inch dry vacuum pump in tandem with the engine cylinder. There is also a five-inch two-stage hot-well pump to pump the water of condensation out of the bottom of the hot well. This pump is driven by a Kerr turbine. All the condensing equipment is furnished by Henry R. Worthington.

There will be three boiler-feed pumps 14 by to by 24 inches for each pair of units. These as well as the service pumps are supplied by the Dean Bros. Steam Pump Works. Each unit will have a feed-water heater of 3,000 square feet heating surface, built by the C. H. Wheeler Manufacturing Company. For the step bearing there will be two 12 by 3 by 12-inch pumps, and for the upper bearing and governor two 5 1/2 by 3 1/2 by 5-inch pumps will be supplied for each unit.

Switch House.

In the switch house, which adjoins the turbine room on the south, the main floor is devoted chiefly to the bus-bar compartments which are arranged similarly to those in the new section of the Fisk Street switch house. The second floor is almost entirely given, up to the oil-switch rooms. At the center of the building the switch house is carried up to a third story, the plan of which shows that its main feature is the operating room. This room will have a glass bay overlooking the entire turbine room. A distinctive feature of the operating room will be that the generator switchboard will be separate from the line switchboard.

In the basement will be cable ducts for the outgoing lines running from the building in a number of conduits. In a part of the basement will be installed a 70-cell storage battery floating on the exciter bus-bars. This will act as an auxiliary for the 150-kilowatt turbine-driven exciters that will, be supplied, one for each generator.

Quarry Street Sub-station.,

At the west end of the switch house will be located a sub-station for use at present principally in supplying direct current to the large number of motors in use around the plant and for lighting the premises. This will contain at first a 500-kilowatt horizontal rotary converter of the split-pole type that does not require a regulator. This type was recently described in a paper before the American Institute of Electrical Engineers by Mr. Stone. The subsequent addition of two 1,000-kilowatt vertical rotaries is contemplated.

General Features.

Among the distinctive features about the Quarry Street station is its compactness, which gives tit an enormous capacity for its size. This is due to the great output of its units as well as to the careful arrangement of these units and their auxiliaries. Mostly all the auxiliaries will be steam-driven, thus giving a larger quantity of exhaust steam for the feed-water heaters. While the Quarry Street station will not have the unique relations to steam-turbine development possessed by its neighbor across the river, it probably will achieve some startling results in the net economy of generating electrical energy in a large central station.

TRANSMISSION SYSTEM.

The first transmission system from a generating station to a sub-station in Chicago was installed in 1894 on the completion of the Harrison Street station. It was an extraordinary underground line of 66,000,000 circular mils total cross-section and a length of 3,400 feet from the new station to what became the first sub-station at 139 Adams Street, when the generating units there were dismantled. This 250-volt Edison three-wire direct-current line is still in service.

The cost of the installation of such lines with the growth of the system being practically prohibitive, and as high-voltage alternating-current transmission had already proved itself efficacious, it was determined to adopt this method as soon as the perfection of the rotary converter made it feasible to apply it 'in the Edison system. What is believed to be the first commercial application of the rotary converter in transmission work was started in August, 1897, with three of these machines, by the Chicago Edison Company. A 250-kilowatt rotary at the Harrison Street station was run inverted, i. e., taking direct current from the 250-volt bus-bars and converting it into three-phase, 25-cycle alternating current, which was stepped up by transformers to about 2,250 volts and transmitted in 2.7 miles of three-conductor No. 0 underground cable to the station at Twenty-seventh Street and Wabash Avenue. At this point it was stepped down to about 85 volts and reconverted to direct current at 125 volts by two 100-kilowatt rotaries. These machines were put in series and helped supply the 250-volt Edison three-wire system, fed from this station. The three machines used in this historic installation are still in service for the company.

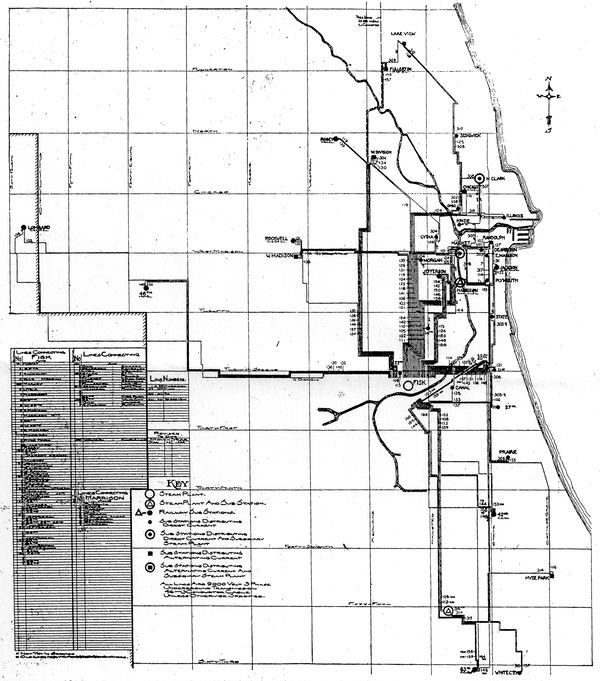

|

| Map of 9,000-Volt Transmission System of Commonwealth Edison Company. |

From this modest beginning the transmission system of the Commonwealth Edison Company has grown steadily in a little over a decade to have almost exactly too times the mileage of high-tension underground cables. The voltage of the transmission system has been raised to 9,000, and this is the potential of all lines running from both the Fisk Street and Harrison Street stations. The diagram of the 9,000-volt transmission system shown gives a better idea of the extent of the system than is expressed by saying it consists of 270 miles of three-conductor cables.

The transmission voltage is generated directly without the need of step-up transformation. The insulation of mostly all outlying lines installed recently is capable of withstanding 20,000 volts, this value being designed ultimately for all lines running to remote sub-stations. One of these 20,000-volt lines is already in service. It runs underground is miles from the Division Street sub-station, where the current from Fisk Street is stepped up to over double its pressure, to the Evanston sub-station of the North Shore Electric Company.

The standard size of transmission cables for 9,000-volt lines is No. 0000; for 20,000-volt lines No. 00. They are paper-insulated and lead-covered and laid in vitrified clay conduits with manholes about 500 feet apart. In the manholes and in the station buildings between the walls and the oil switches these cables are further covered with split tiles as a protection against mechanical injury.

To carry the transmission cables across the Chicago River and its branches six special tunnels have been built in the following order: Harrison Street, Washington Street, Indiana Street, Quarry Street, Twenty-second Street and Clybourn Place. The one at Quarry Street is built in solid rock. The last five tunnels were built in the last five years. They are of concrete and have an inside height of 6 1/2 feet, and, with one exception, a width of six feet. Their average length is about 360 feet. In these tunnels the cables are arranged in isolated groups and carried up through the terminal shafts in this manner, and to separate manholes in many cases. The shafts are carefully designed to minimize any strains on the cables, eliminate crossovers, and to provide conveniently for any extensions or repairs.

All important sub-stations are connected directly with the generating station by one or more transmission lines and to one or more adjacent substations by a tie line or lines. Ordinarily these tie lines are left open to prevent extensive disturbance by a ground or short-circuit on any part of the transmission system. In case of a breakdown in one of the main lines, however, these tie lines immediately become available as an indirect connection to the 'source of supply through another substation. These tie lines are well shown in the map of the 9,000-volt system referred to.

SUB-STATIONS AND DISTRIBUTION.

SUB-STATION GROWTH.

Since 1897, when the first transmission system was put in operation in Chicago, as described above, the number of sub-stations has rapidly grown and the number of generating stations has simultaneously diminished. The Commonwealth Edison Company has now 32 sub-stations in its own system and there are it more supplied with current by the system but owned and operated by the surface and elevated railway companies. The map already referred to shows the location of most of the sub-stations.

Three of the company's sub-stations are equipped with storage batteries only, 21 with rotary converters, four with motor-generator frequency changers, two with rotaries and frequency changers and two with step-down transformers only. Three sub-stations are provided with steam auxiliaries for winter peak load and emergency service. A number of the sub-stations are equipped with storage-battery auxiliaries, there being altogether 20 batteries in the system, with an aggregate capacity at the one-hour rate of discharge of 17,700 kilowatts. The rotary converters range in size from 100 to 2,000 kilowatts and have a total capacity of about 52,000 kilowatts. The frequency changers range from 250 to 2,000 kilowatts, with an aggregate capacity of about 22,000 kilowatts. The railway sub-stations contain rotary converters with a total capacity of nearly 50,000 kilowatts; some of them also have auxiliary storage batteries.

DISTRIBUTION SYSTEM.

In the central business district, bounded by the' lake, the river and Harrison Street, and having an area of less than one square mile, there are to sub-stations carrying the densest load of the system. Lying about this is a zone of 15 to 18 square miles extent, where the load is fairly concentrated. The distribution from the sub-stations in these two areas is direct current on the well-known Edison three-wire system at 250/125 volts. These areas of direct-current distribution are within the old city limits which formed the operating territory of the old Chicago Edison Company. The direct-current network comprises about 118 1/2 miles of underground feeders.

The distribution in the zone outside this area and comprising the remainder of the city is entirely by alternating current at 6o cycles. The substations in this zone contain frequency-changing motor-generators. These change the 9,000-volt, 25-cycle current ,from Fisk Street to 4,000/2,300-volt, 6o-cycle current. The generators are Y-wound and supply energy to the four-wire, three-phase distributing network. All but the smallest motors and large sections of the lighting load are run from the three-phase circuits directly. Residence lighting is largely supplied from single-phase branches of these circuits. While it would be feasible to carry the motor load direct on 25 cycles, it is not advisable to run the lighting load at so low a frequency. To avoid too great complexity of circuits, all the load is run on 60 cycles.

An exception to the standard adopted for the 60-cycle distribution is in the method of feeding the two farthest south sub-stations in the city, South Chicago and Fernwood. Feeders from the Hyde Park and Fifty-sixth Street sub-stations are run to these outlying ones, carrying 6o-cycle current that has been stepped up to 8,250 volts. At the remote sub-stations this is merely stepped down for local distribution at 4,000/2,300 volts.

The 6o-cycle distributing system, ramifying the outlying parts of the city, where the load is frequently widely scattered, is carried largely overhead, although a steadily increasing part of it is being put underground. It aggregates now about 3,600 miles of equivalent single-conductor overhead and about 28o miles single-conductor underground.

SUB-STATION EQUIPMENT.

In general the equipment of the various sub-stations has become more and more standardized along the lines established several years ago. A _ few changes are to be noted, however. The sizes of the units installed has steadily increased. In some of the sub-stations scarcity of room had to be contended with. To meet this difficulty vertical machines have been developed that have proved very satisfactory.

A vertical frequency changer is shown in the view of the Hyde Park sub-station. The motor is a three-phase, 25-cycle, 9,000-volt synchronous machine with revolving field. The generator is a 6o-cycle, 4,000/2,300-volt, four-wire, three-phase machine, also with revolving field. A too-kilowatt exciter is mounted on top of the machine. The unit is rated at 2,000 kilowatts. The view also shows two horizontal 1,000-kilowatt frequency changers.

Another view shows the new 2,000-kilowatt vertical rotary converter at Market Street sub-station. It has been running about half a year with excellent results, It gives not only more floor space but enables more convenient and accurate adjustment of the brushes and is more accessible in every way. It was first described in the Western Electrician of December 14, 1907. This sub-station is also equipped with four horizontal 1,000-kilowatt rotaries.

GROWTH OF THE SERVICE.

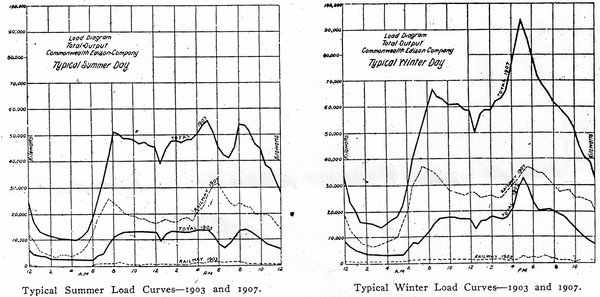

Some conception of the great extent of the system may have been obtained from the foregoing portions of this article. The diagram showing increase in generating capacity gives a good idea of how rapidly the generating equipment has been increased to keep pace with the demands on the system. A very forcible demonstration of the extraordinary increase in these demands is given by the accompanying typical load diagrams.

Close study of these load curves reveals many interesting facts. In 1903 both the summer and winter curves were not unlike those of any large central-station company that has developed considerable day load, particularly in motors. Four years later there was an increase of more than three times the total load, and the winter curve showed that the customary peak had become of relatively less importance.

Most interesting, however, is the series of dotted curves marked "Railway." These show that from a very small proportion in 1903 the railway load has increased to nearly half of the total load in 1907. Last year the railway load alone was over 50 per cent. greater than the total load of 1903. As this traction load has been developed in such a rapid manner and as this development has been entirely distinctive of Chicago, it is worth while considering it in more detail.

RAILWAY LOAD.

Local traction conditions had an important bearing on the development of this load. The uncertainty of franchise renewal on their expiring grants prevented the street-railway companies from raising the capital requisite for enlarging or rebuilding their power plants to keep up with the growing traffic. Some of these plants were uneconomical and out of date; a few of them contained small generators belt-driven from simple non-condensing engines that were supplied by fire-tube boilers, hand fired. One elevated-railway company never had built a power house of its own. It bought its current from two of the street-railway companies.

When these could not furnish an adequate supply, it found that the centralstation company could, and so the first railway substation was located at Lake and Rockwell streets in 1902.

The readiness with which this service Was established, as well as its convenience and low cost, soon demonstrated to the other companies the desirability of this means for securing additional power, and as a result sub-stations for their, purpose were gradually established. When the old cable lines were electrified a decided in addition to this service resulted. Two other elevated roads adopted this plan, and, in fact, in recent years all the local traction companies except the South Side Elevated have called on the central-station company for additional power.

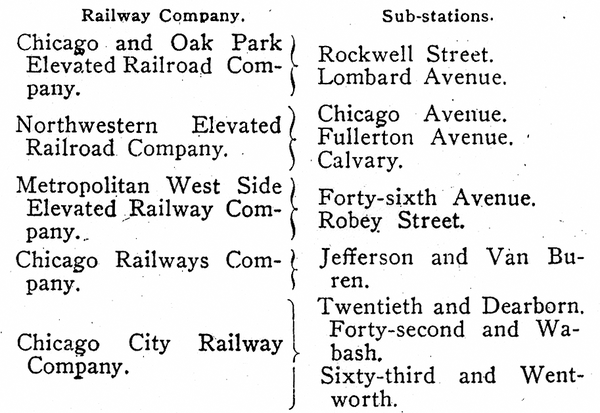

There have now been established II sub-stations devoted exclusively to this service, as follows:

|

These sub-stations are owned and operated by the respective railway companies and are supplied with 9,000-volt, three-phase current by the Commonwealth Edison Company, which is sold at its bus-bars and transmitted in its cables. The Calvary sub-station is supplied at 20,000 volts. This current is reduced in voltage and changed to direct current at 500 to 600 volts at the different sub-stations.

Besides these II sub-stations, one rotary converter at the Plymouth Place sub-station of the Edison company is operated for the Chicago City Railway, and another rotary at the White City sub-station is similarly run for the Calumet and South Chicago Railway Company.

What is not usually classed as a railway load, but is actually used for traction purposes, is the current supplied to the Illinois Tunnel Company, at 250 volts from five rotary converters in three of the Edison downtown sub-stations.

No central-station company has developed anything like such a large railway load as this described above. It is a great credit to the Commonwealth Edison Company that it has so successfully shown the value of this service to the traction companies as well as to its own system. This load will probably grow to enormous proportions, as the company is steadily improving its facilities for producing current cheaply, and is in much better condition to do so even now than the traction companies.

OTHER LARGE CONSUMERS.

Very few central-station companies have made such an aggressive campaign or had such good results in getting new business as the local company here. A great force of energetic and capable solicitors has made a careful canvass of the conditions prevailing with both large and small power consumers in the city. By showing them conclusive figures of the economy and other advantages of central-station service a considerable number of large consumers has been added to the system.

|

| Load Diagrams of Commonwealth Edison Company. |

These include most of the large downtown office buildings, including the two new public edifices—the Federal and County buildings. Almost all the great department stores; including Marshall Field & Co., have abandoned their isolated plants. The ease with which electrification of large establishments can be effected and extended when supplied by the central station has brought about the introduction of motors for much work in these places. An important increase of load in all high buildings has been effected by the rapidly extending use of electric elevators.

Outside the business district a rapidly increasing number of manufacturers has been supplied with electric power. In many cases this has been brought about to increase the power required in the plant instead of adding more engines to it. In many other cases all the power is electrically supplied. At the beginning of this year the aggregate horsepower in connected motors amounted to 171,880.

Among other large consumers must be mentioned White City, one of the most popular summer amusement parks. Here the load was so great that a sub-station had to be installed.

RESIDENCE LOAD.

While electric lighting still remains as the greatest feature of the residence load, considerable success has been met in Chicago in the introduction of cooking, ironing and other miscellaneous domestic uses of current. This has had a good effect on the load factor of this service.

A rapid extension of residence service has taken place in the last few years. Within the last year a very successful policy in the securing of consumers in old residences has been introduced, which provides for the installment plan of payments for wiring the premises. Thus what seems a prohibitive expense is made quite moderate by being spread over two years.

CONCLUSION.

One important element in securing new business and in holding old consumers in Chicago has been a marked and steady reduction of rates for electrical energy. Thus in the last 10 years there has been a voluntary reduction of something like 50 per cent. in the rates for electric lighting alone. In accordance with a recent ordinance sanctioning the consolidation effected September 17, 1907, of the Chicago Edison Company and the Commonwealth Electric Company into the present corporation, further reductions in rates are provided for. In 1909 the rates will be but 40 per cent. of those in effect 10 years ago.

These reductions in rates were made possible only by economic management of the entire industry. Economy in the production and, distribution of the current have been most marked and are readily apparent. Other administrative economies have been no less real, even if not so evident. That further economies are to be effected is quite certain.

Other branches of the company's activity that have contributed to its success in its dealings with its many consumers are the sales, wiring, repair, testing, and publicity departments. A well-equipped laboratory is maintained for testing of meters and all kinds of electrical instruments and machinery.

The publicity department looks after the extensive advertising of the company, an important feature of which is the monthly publication, The Electric City. How well the company has succeeded in rendering Chicago the real electric city is attested by the stupendous increase in the connected load of the company, which has risen in 10 years from an equivalent of 600,000 16-candlepower incandescent lamps to a total of over 3,884,000, exclusive of railway load, at the beginning of the present year.