[Trade Journal]

Publication: Electrical Review and Western Electrician

Chicago, IL, United States

vol. 55, no. 16, p. 756, col. 1-3

Westinghouse Strain Insulators.

The necessity of having a power line well insulated, with the conductors securely in place and taut, is well recognized; but the difficulties encountered in erecting such a line are also realized by the constructing engineer. The fragile nature of most insulating material, and the high stresses involved in line construction, render the design of effective insulators very difficult. On the other hand, the economy of high line voltage is a stimulus to the engineer to devise insulators that will withstand heavy electrical and mechanical stresses, because it has been found that the line potentials are only limited by the strength of the insulators available.

| |||

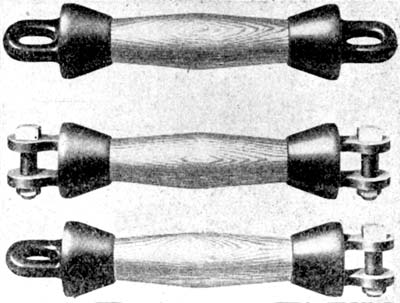

| Westinghouse Wood Strain Insulators. |

The Westinghouse company is marketing a line of insulators which are claimed to solve the insulator problem. These strain insulators include types for any duty that may be required in modern line construction, and are the result of careful research in conjunction with an efficient manufacturing system.

The type adapted to the greatest variety of requirements is known as the wood strain insulator. These insulators are made in various strengths, so that an effective and economical style of insulator is available for any service. They are designed for a working pull up to 4,000 pounds, and single insulators are adapted to voltages ranging from 150 to 11,000 volts. For higher potentials they may be connected end to end in series. The construction of these insulators possesses many inherent advantages, among which are low first cost and long life. The metal parts are furnished in a galvanized finish, which will withstand any atmospheric conditions, and the wood parts are especially treated and sealed to render them thoroughly moisture-proof.

The end caps are secured to the body by being pressed around the taper shafts on the ends of the wood. This method of securing the caps insures a reliable joint whose strength equals that of the wood or the metal eye. As the wood body is not fragile, like most insulating material, it is not subject to breakage from impact.

The end caps are provided with eyes, clevises or tapped lugs, which adapt the insulator for dead-end, anchor guy or steady strain service.

| |||

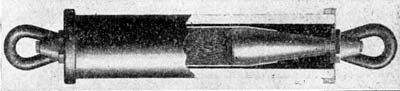

| Construction of Westinghouse Type C Insulator. |

For high-tension lines, the Westinghouse type C insulator is a new and interesting development. The insulator is tested at 40,000 volts before shipment, and its ultimate mechanical strength is upward of 30,000 pounds in tension. For service voltages up to 12,000, and for mechanical strains up to one-third, or in special cases one-half, of the ultimate strength, the type C insulator may be used with entire success. The construction is shown herewith.

A pull on the eyebolts acts directly on the insulating cone to produce compression. This cone is constructed of sheet mica, under heavy pressure, and will withstand a heavy stress. The outside tube is of porcelain, and, being twenty inches long, offers ample creepage distance in any weather. It has no fragile petticoats and is quite inconspicuous. The porcelain acts only as a weather seal and is relieved of any mechanical strain.

The line of high-potential insulators includes disk and skirt types, which excel all others in their respective classes.

The line of low-voltage strain insulators includes Globe, Giant and Brooklyn types, which have been found very efficient in their several classes of service. The adjustable ties include two insulated turnbuckles. One has a porcelain insulator and the other has its eye molded in a special Westinghouse company. This is the same compound used on the Globe, Giant and Brooklyn types, and combines great insulating resistance, with stable structure, in the most extreme climates.