[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 56, no. 1, p. 25-27, col. 1-2

MECHANICAL TESTS OF INSULATOR PORCELAIN AND GLASS.

By Ralph P. Clarkson.

RECENTLY it was found desirable to investigate high voltage insulators for lines carrying upward of 125,000 volts and it was necessary to know something of the mechanical strength of those materials most commonly used for insulating purposes. Recent engineering literature and such reference books as could be obtained were searched for information as to mechanical tests of porcelain and glass, and for the methods of making such tests; but no illustrated article was found, and only the very slightest information that such tests were ever published. The writer, therefore, conducted the following experimental tests in the well-equipped laboratory of the Worcester Polytechnic Institute and offers them, not as exhaustive, but simply to show in general what users of insulators may expect.

|

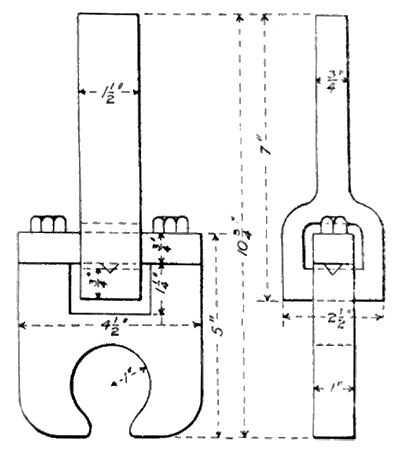

| Fig. 1 -- Shape of Glass Briquettes. |

| |||

| Fig. 2 -- Flaws in Porcelain. |

| |||

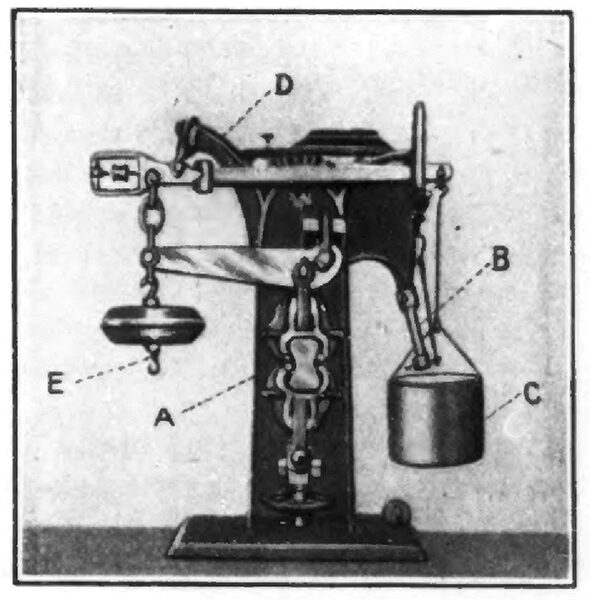

| Fig. 3 -- Fairbanks Concrete Testing Machine. |

|

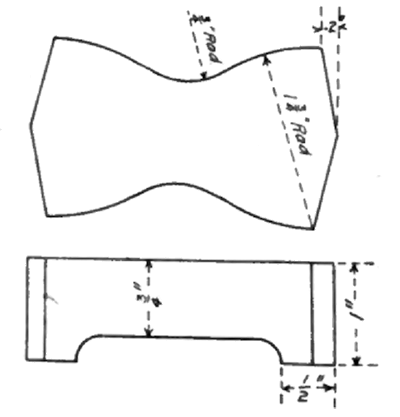

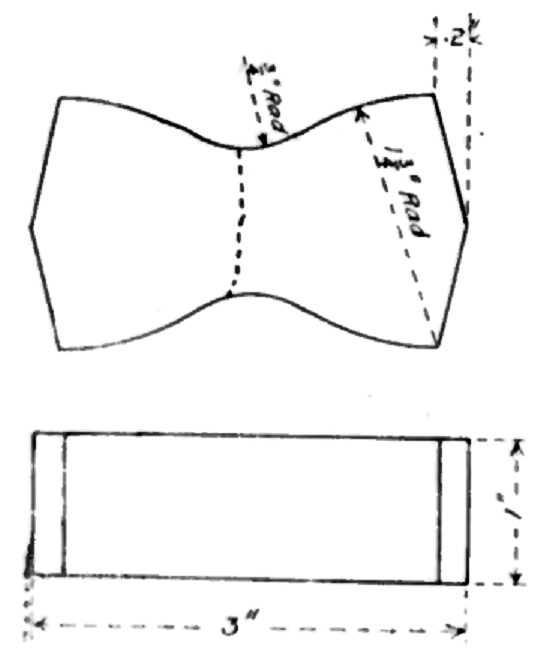

| Fig. 4 -- Design for Cast-Iron Holding Clip. |

The requirements of a good insulator are many, but the chief one is that it must be of low price. This limits the material of which the insulator may be made, and glass and porcelain seem to be the best because of their mechanical as well as dielectric strength. Of these two substances, glass is the better in a great many ways, but it has not been made into as good an insulator as the porcelain except at a much greater expense. Glass appears to be more homogeneous and flaws are easily detected by the eye. There are no dark corners where insects can build their nests. It is also less hygroscopic than porcelain, but does not possess the mechanical strength. The subject of making an electrically and mechanically strong glass has not received the attention it deserves from a chemical standpoint. It is known that glass made for other purposes by the famous Jena glass works has been found to possess electrical properties superior to any usually found and that that glass is very free from any tendency toward surface disintegration.

Because of the above facts, which were known to the writer, and because of the difficulty in obtaining fair glass cubes, only tension tests of glass were made. The glass used was obtained from a prominent manufacturer and the samples were taken from a batch of ordinary insulator glass, having been made about three years before the tests on them were conducted.

Both glazed and unglazed porcelain samples were tested in tension and compression, and the results investigated. All the porcelain was made from a standard formula and was identical with that from which a high-class line of high-voltage insulators are made and the glaze was the standard glaze used on that line of insulators.

It was desired that the tests should be made on standard shapes of materials in order that the results should be easily understood and comparable with other experiments. The shape of the samples of porcelain tested in tension was the standard briquette recommended by the American Society of Civil Engineers for tension tests of cement. It was impossible to get the glass in exactly that shape, but Fig. 1 shows the form used, this differing in no essential point from the shape recommended. The porcelain was, however, obtained very near the standard form, shrinkage causing some variation from the dimensions. The samples of glazed and unglazed porcelain were in the shape of a cube for the compression tests. Their size varied, but a large number of 1 in. on an edge were tested. The porcelain used was not in any sense special, and the flaws found in all insulators were found in these samples. Fig. 2 gives an idea of what those flaws were a large, round, very hard piece of porcelain imbedded or an open crack where the clay did not stick together.

The testing machines used were standard instruments. For tension tests of glass the Fairbanks briquette testing machine was used, but this has a capacity of only 1000 lb. so that a Wicksteed 20,000-lb. testing machine was used for the porcelain tests, both in compression and tension, except in a very few cases, which were not recorded, when an Emory hydraulic testing machine having a capacity of 100,000 lb. was used, simply to investigate the peculiar fracture and to see if it was due to the method of applying the load.

The Fairbanks machine is shown in Fig. 3. The briquette is held in brass clips at A and the weight applied uniformly by a stream of shot which runs from a reservoir through the tube B into the pail C suspended at the end of the steel yardarm upon which the weight D slides. When the briquette breaks, the arm falls, automatically cutting off the flow of shot. The shot is then weighed by means of the balance at E. The rate of applying the weight or load was about 475 lb. per minute.

The Wicksteed machine is merely a system of levers by means of which the load is applied by hand, or otherwise, and then balanced by the sliding weight so that readings may be taken directly.

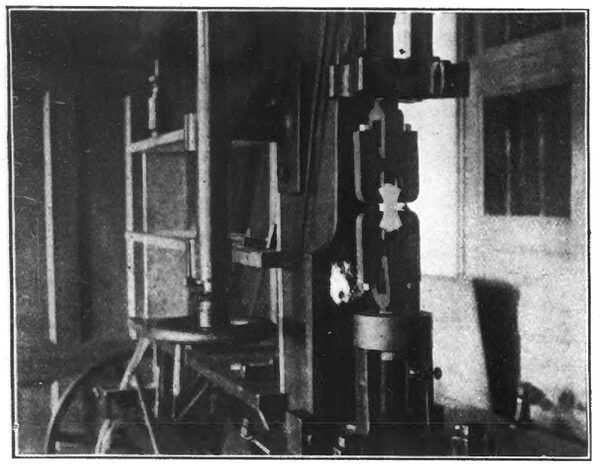

The clips by means of which the briquette is held and the stress applied are the most important part of the testing machine. Brass clips were used for the glass samples, and were satisfactory, but in order to test the porcelain it was necessary to make very heavy clips so that they would not spread when the load was applied to the briquettes. Cast-iron clips were obtained in accordance with the design shown in Fig. 4 and were found to work very satisfactorily. Fig. 5 shows the clips in use on the Wicksteed machine, an unglazed porcelain briquette being in place.

| |||

| Fig. 5 -- Porcelain Briquette Under Test. |

|

| Fig. 6 -- Standard Form of Briquette. |

To a great extent the methods used in testing cement were followed. Care was taken to center the briquettes carefully in the clips and then a slight initial load was applied and the zero reading taken. For the tension tests of the porcelain the load was applied by steps of 100 lb. up to 1000 lb. and then in steps of 50 lb. until the sample broke. Each load was carefully balanced by means of the sliding weight so that the results are very accurate.

Considerable difficulty was encountered in getting the porcelain to break at the smallest cross-section, but finally by using pillows of cardboard between the clips and the briquettes the break occurred, in most cases, very near to the smallest section. It is not to be expected, however, that the smallest section is necessarily always the weakest when porcelain is used. This is due to two causes, and these are the factors which make porcelain so uncertain in its actions. First, the smallest section is, of course, more thoroughly bakes than a large section of the same piece. Secondly, the flaws shown in Fig. 2 are very frequently found in a large piece of porcelain and, many times, they are the determining factor in finding the strength. The lack of homogeneity in porcelain is a serious drawback.

Fig 6 shows the shape of briquette recommended by the American Society of Civil Engineers, and the dotted line shows how the majority of fractures ran. The breaks were all clean and even, and the samples showed no signs of being crushed at the sides or of splintering.

It may be of interest to note the method of computing the section where the break occurred. It seemed very much of a problem to do this accurately, but the plan finally adopted seemed to give as close results as any. The specimen was placed upon sensitized paper, such as will be turned black by contact with brass (ordinary steam-engine indicator cards were used), and a sharp brass needle point was used to mark around the section. Both halves of the sample were used in each case, and each traced around a number of times. The area thus obtained was integrated with a planimeter.

|

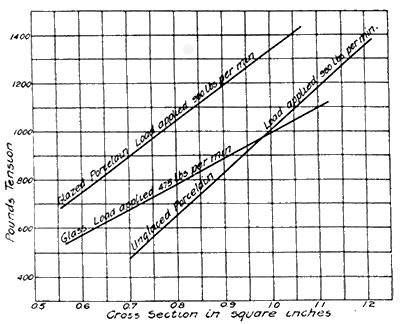

| Fig. 7 -- Tests of Tensile Strength. |

|

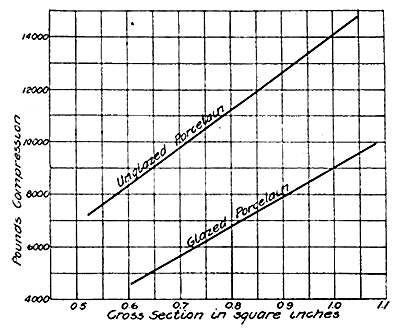

| Fig. 8 -- Tests of Compressive Stength. |

Fig. 7 gives a curve sheet showing the results of the tension tests using glass, glazed porcelain and unglazed porcelain. The cubes used for the compression tests did not have perfectly flat faces and so it was necessary to provide even bearing surfaces for them that the breaks might be in compression and not in tension of shear. It was found that it is possible to grind the unglazed porcelain with a coarse emery of corundum wheel, but the grinding must be done very slowly and carefully or the surface become all glazed over. The plan decided upon in this case was to bed the cubes on lead sheets about 1/16 in. thick. When the load was applied the lead flowed slightly and very thinly around the edges and curled up, thus possibly giving some very slight additional strength to the cubes.

The porcelain fiber showed up better in these tests than in any other tests of the substance. The fracture took place in lines at right angles to the face of the jaws so that the specimens, instead of crushing as many substances do, splintered into a number of pieces. Different beddings, different rates of applying the load and different methods of applying the load were all tried, but the fracture was always the same. The curve sheet. Fig. 8, shows the results of the compression tests on both the glazed and unglazed samples.

The conclusions which might be drawn from these tests are very many. In tension glass and unglazed porcelain have about the same strength. Glazed porcelain is about 25 per cent stronger than either. This is to be expected as glaze would probably have the same effect as the scale does on cast iron. In compression unglazed porcelain seems to be stronger than glazed, but the strength of porcelain in compression is from 10 to 12 times its strength in tension. It is rare that such a proportion is found with the more common substances used in construction, cast iron being a fair sample of the proportion usually found, five to one.

The writer believes that tests of porcelain beams would be of great value in the study of that substance, especially cantilever beams, as that is usually the way that insulators are strained. Such tests would assist materially in the study of the work outlined above.