[Trade Journal]

Publication: Electrical Review and Western Electrician

Chicago, IL, United States

vol. 69, no. 12, p. 524-525, col. 1-2

Manufacturing Electrical Porcelain Under Modern Conditions.

For many forms of electrical equipment porcelain insulation, because of its mechanical and dielectric characteristics, is conceded to be the most adaptable and secure from hazard in its application.

The manufacture of electrical porcelain has been brought to a high degree of perfection in this country. The science and art of ceramics and pottery, as a matter of fact, for practical utilization for domestic and industrial purposes, has been advanced by American manufacturers far beyond the realization of most of the people utilizing these materials.

| |||

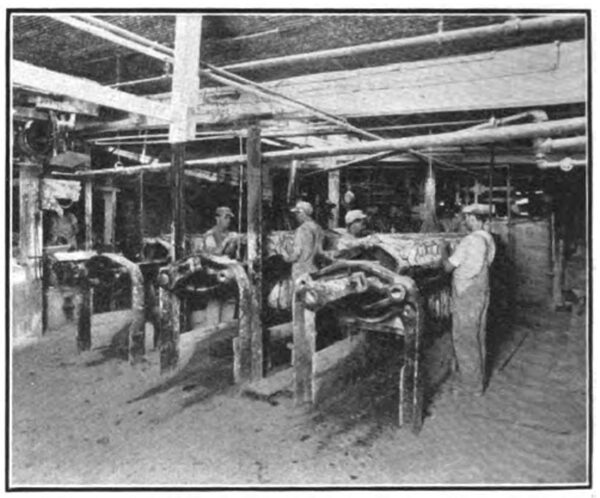

| View in Slip House Where Ingredients Are Mixed. |

The manufacture of electrical porcelain requires a constant supply of proper ingredients, a thorough knowledge of manufacturing methods, plant equipment for scientifically carrying out the various methods of manufacture, and a working organization trained to accomplish each element of the process involved in an intelligent and skillful manner.

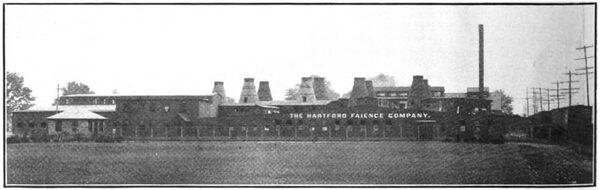

A noteworthy example of present-day methods of manufacturing electrical porcelain is that of the Hartford Faience Company, whose plant is located at Hartford, Conn., on the lines of the New York, New Haven & Hartford Railroad. The accompanying general illustration of the plant presents a view from the north. This plant is equipped with nine kilns and produces electrical porcelain from tiny buttons to the largest molded forms. The plant is devoted entirely to the manufacture of electrical porcelain from the specifications of the builders of electrical equipment of every description.

| |||

| General View of Factory of Hartford Faience Company. |

Broadly speaking, the body of porcelain consists of purified kaolin, finely ground felspathic rock and quartz sand. The formula varies with the character of the product to be arrived at, and the quantitative admixture is the result of carefully worked out researches upon the part of the laboratory equipment of the manufacturer.

The ingredients of the porcelain body are mixed wet in a large plunger or tumbler, the contents being kept in constant motion by rotating arms. When thoroughly mixed this is called "slip" and is allowed to run by gravitation through a lawn or sieve (120 mesh to the inch) into an agitator which is a large receptacle placed below the surface of the floor. The agitator is also equipped will rotating arms, keeping the "slip" in constant motion. The "slip" is pumped from the agitator into filter presses which allow the water to filter through canvas bags but retain the clay. After being taken from the filter presses the clay cakes, are dried to a certain extent, then passed through a spider grinder and deposited in a dust box. The clay or body is then sieved and is ready for pressing. Great care must be exercised in the mixing of the body, as in the process of manufacture a shrinkage in size of approximately 12.5 per cent takes place. This is allowed for in the mold, but any deviation from the correct formula would cause a variation in the shrinkage that would be disastrous.

| |||

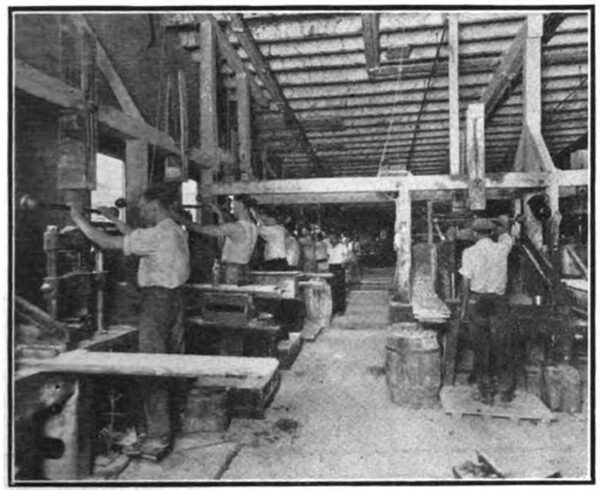

| Pressing Department Were Clay is Molded. |

| |||

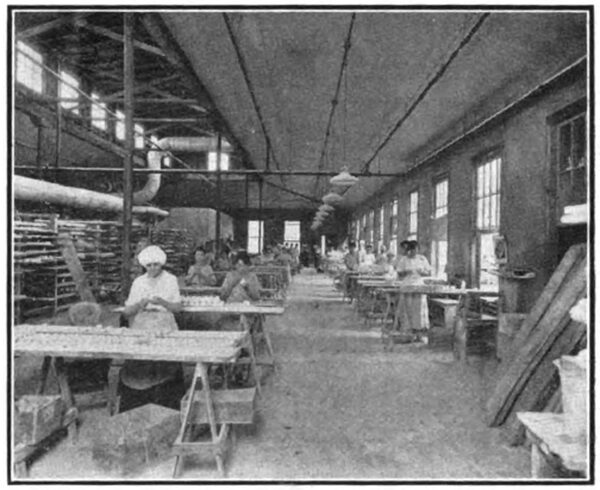

| Cleaning and Glazing Department. |

The finely comminuted and partly dried clay is placed in a steel mold and pressed to correct size and form in a hand-screw press. The piece when pressed is forced from the mold by a bottom follower which is operated by a foot lever.

The ware after being pressed is placed in driers and when thoroughly dried goes to the cleaning and glazing department where the burrs or fins are cleaned off and the glaze is applied. The cleaning is done with a pencil of wood, or a special knife blade, and a glaze is applied by painting, dipping or spraying, according to the design of the piece. All of this work must necessarily be done by hand. After cleaning and glazing, the ware is ready for firing or baking and is placed on boards and put in racks at points conveniently reached by the kiln placers.

Hartford porcelain is made by the one-fire process—that is the ware is fired once only whether glazed or unglazed. Clay pots called "saggers" are filled with the ware to go into the kilns and these "saggers" are stacked up one upon the top of the other all around the sides and filling completely the kiln. When the kiln is filled the door is bricked up, immense metal bands are cemented into place, and the fires are lighted. These fires are served from six apertures around the periphery of the kiln. The fires are maintained until the temperature inside the kiln reaches approximately 2,550 degrees Fahrenheit, the time required for firing being about 32 to 40 hours.

All of this, by the way, must seem to be entirely mechanical. There is involved, however, in every part of the process an intelligent conception of the work being done, and skill and experience, the lack of which would render impossible the production of finished material fit to pass the rigid inspection required by these manufacturers. First of all, the ingredients must be correct; the composition must be absolutely as provided for in the formula; the time element involved in the mixing, and the proportions allowed with the narrow limits provided for shrinkage in the mold, call for the greatest attention to every individual detail.

In handling the clay or body as it is stuffed into the molds, then bringing the dies together with just the right amount of pressure, and then following up the release of this pressure with the ejector; the removal of this semi-plastic form from the molding press, and then the delicacy with which the fins or burrs must be removed, all call for workmanship above the average.

After the fins have been removed, the wares must still be very carefully handled, so as to result in no deformation, and assembled carefully in the "saggers" and then fired under conditions of uniformity calling for constant watchfulness in order that color and accuracy in size may be maintained.

Another important element in the production of high-class electrical porcelain is in the manufacture of the steel molds in which the porcelain is pressed. This is one of the most important parts of the industry and is one of the foundations upon which depends the accuracy in dimensions of the finished product. The Hartford molds are made by skilled mechanics.

The accompanying illustrations are reproduced from views taken in the plant of the Hartford Faience Company, and will give the reader a fairly good idea of the mechanical processes involved and the provision the company has made to skillfully carry out these various processes.