[Trade Journal]

Publication: Electric Journal

Pittsburgh, PA, United States

vol. 15, no. 12, p. 489-492, col. 1-2

The Design of Porcelain Insulators from the Ceramic Standpoint

G. I. GILCHRIST and T. A. KLINEFELTER

THE manufacture of porcelain insulators involves the consideration of a number of factors aside from those of a mechanical and electrical nature. Practically every line and section of an insulator must be modified more or less from what would be strictly correct from the theoretical standpoint.

After the preparation of the clay by one of the processes previously described (1), the insulators are made by hand or machine jiggering, by dry pressing, or by turning and casting. For each method particular tools and methods of handling the clay body are required. If the same body is used for each process, it will be found that not only must the design be modified especially for each but that different shrinkages take place, and a different texture and structure of the porcelain itself result. The designer must keep all of these conditions in mind, since every detail in manufacture may require a modification especially adapted to the process by which the insulator is to be made.

Since most high-tension insulators are made by the wet process, some of the important factors affecting design for this method will be given attention. The production of these insulators is accomplished by jiggering or by use of the hot press machine, the latter being a mechanical modification of jiggering. If the insulator is to be jiggered it will be formed in a one piece mold and set aside to dry for several hours. At the end of this time the plaster mold will have drawn out of the insulator a certain amount of water, causing it to shrink and loosen from the mold. The mold is turned upside down and the insulator should slip out instantly, requiring no jarring or pounding. Being only partially dry, a heavy, or sometimes a slight jar will distort the shape of the insulator. Any subsequent attempt to restore the shape may set up enough internal strain to result in cracked or distorted ware during the burn. Obviously the insulator most have enough slope or draft so that it will slip out at once, when the mold is inverted. For the same reason, and also because of the shrinkage, there must be no shoulders or projections to catch on the mold when the piece starts to pull away from it.

| |||

| Fig. 1 — Hot Press Machine |

The inner part of the insulator is formed by a shoe which either comes down in the arc of a circle, or drops vertically. If the insulator is a deep one, the designer must be careful that the jigger shoe, as it lifts out, will not gouge and distort the formed piece, otherwise the shoe must be dropped vertically, which is more expensive.

In some types of insulators, especially the suspension type, there are a number of corrugations. These must not be too thin or too deep. The thinner and deeper they are the more difficult it is to make the insulator. In a practical design the width of the corrugation should increase with the depth.

While the hot press machine jiggers automatically and hence should give greater accuracy in forming, it also gives a greater amount of trouble in other respects which do not appear in hand jiggering.

The clay body is difficult to keep absolutely uniform in moisture content and working quality and texture. On the jigger wheel this is easily taken care of, as the workman can use a little more or a little less water, and in general he can work the clay a trifle more and obtain a good product. With the hot press machine no matter what the condition of the clay, it receives the same treatment. Sometimes internal stresses result, due to the twisting motion of the plunger; sometimes it is simply an annoying sticking of the clay to the plunger, etc. These various things can be modified to some extent by proper design. Very thin petticoats, for instance, are likely to suck and draw, or stick to the die if the clay is a trifle too soft. An insulator with fins (such as a few of the small pintype), which in the mold constitute side passages, are hard to fill properly if the clay is not in quite proper working condition. Obviously too, these side passages will not be packed so tightly as the clay receiving the main thrust of the plunger. This results in a variation of shrinkage with subsequent cracking, if the stress set up becomes too great. Incidentally an objectionable feature of insulators with fins is that they must be made in a split mold. Since it is possible to use a mold split in half on these machines, there has been a tendency to design shapes which can be made in no other way. The practice is bad, however, not only from the standpoint of cost, due to greater breakage of molds, but the insulators are likely to be of inferior quality, and are more likely to have internal strains set up in them, with resulting by cracking.

| |||

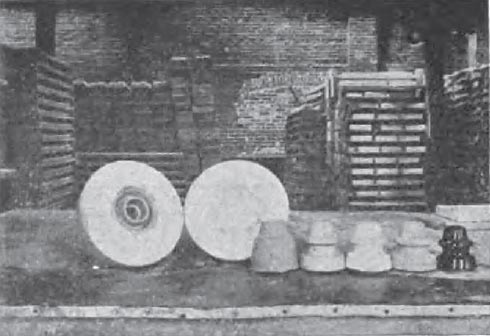

| Fig. 2 — Hot Press Insulators in Various Stages of Production From Left to Right: 1—Insulator in Mould. 2—Plaster of Paris Mould. 3—Insulator Removed From Mould. 4—Insulator Trimmed. 5—Insulator Bone Dry. 6—Insulator Glazed. 7—Insulator Fired. |

One of these hot press machines is shown in Fig. 1, and Fig. 2 shows a mold, an insulator just moved from the mold, a trimmed unit, a dried unit, a glazed unit and a burned unit. An interesting investigation was recently conducted, covering the manufacture of several thousand of these insulators in an effort to determine the various factors causing the differences in ware made on these hot press machines. First, the pugged blank from which the insulator is made was varied. In one case a cylinder of clay of just the right diameter was tried, then a large cylinder divided into quarters and halves. The blanks were run soft, then quite stiff. Finally each different kind of blank was tested as to the best manner of patting into shape by hand, and throwing into the mold.

It was found that there was really a factor of considerable variation with each of these conditions. It makes a difference whether the clay is stiff or soft, the kind of blanks used, the method of handling the clay and throwing it into the mold, the general speed in working etc. Moreover, the accuracy of the machine-itself is a factor, for if the plunger is not aligned correctly, the ware will crack very quickly on the inside.

| |||

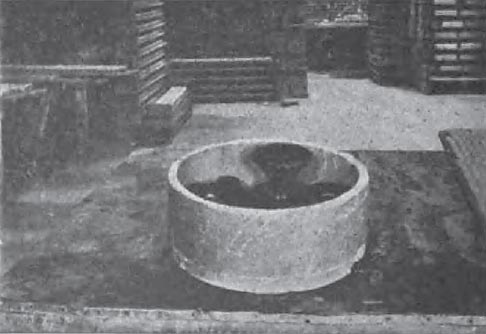

| Fig. 3 — Fired Insulators in Sagger — After Drawing From Kiln. |

The error in alignment may be so small as to be undetectable by the eye and yet cracking will result in less than a half hour. The human factor enters in at so many points that considerable differences are to be expected. A difference of ten percent in cracked ware was found in the product of a number of long experienced hands.

On further study it is found that modifying the design changes the result of some of these factors greatly, some designs being extremely sensitive at stages of manufacture where others seem to stand almost any type of handling. The same factors regarding draft for removing the insulators from the mold applies to the hot press process as well as to the mold for hand jiggering. There are also the same limitations with regard to depth and thickness of corrugations.

After ware has been made by either process, it is ready for trimming, or it may be allowed to dry out thoroughly and then be trimmed. There are advantages in both ways, some designs being more easily handled one way than the other. In either case, the designers must consider how the ware is to be trimmed and what the limits are. There is a chance of breakage and distortion in the trimming, especially if the piece has thin corrugations, or if it must be under cut. The less material there is to take off, the better, and the simpler and straighter the motions necessary, the better.

One of the main operations is drying. Here, aside from the factors already mentioned, the greatest and most important factor is that of section. Within reasonable limits, the thinner the section the better, since the drying takes place much more rapidly than where the section is thick. However, even more important is the necessity of keeping all sections as nearly uniform as possible. If this is done the shrinkage rate is practically the same throughout the piece and no new strains are set up. If, however, the thickness of a section changes abruptly, almost invariably cracks will appear in a large proportion of the insulators at the junction of the thick and thin parts. Too sharp a corner or abrupt a change in direction will also cause cracking. A change in direction should always take place gradually.

The sharp corner or edge is also sure to give trouble in respect to the next operation, that of glazing. Although the glaze becomes liquid during burning, it is generally quite viscous and the surface tension will pull the glaze away from sharp edges and flood abrupt corners. With a dark glaze this results in light lines on the edges, and dark in the corners, and sometimes crazing in the latter case if the glaze is too, thick.

The final factors in the process deal with the kiln. The ordinary jiggered or hot pressed ware usually gives little trouble from warping, since it is generally heavy enough to hold its shape through the burn. Most of the trouble appears from too small a placing surface. The method of placing insulators in a sagger is shown in Fig. 3. Obviously the insulator must rest on one of its surfaces, which should be unglazed if possible. The designer too often gives this little attention and as a result the insulator has a small placing surface, and a high center of gravity. Therefore the least motion in the kiln causes it to upset, spoiling not only that particular piece of ware, but others near it.

If the surface is left glazed, it must be placed on some arrangement such as fireclay stilts or crushed quartz so that the glaze will not come in contact with the bottom of the sagger, with resultant sticking. Resorting to such methods is costly in itself and often results in a goodly percentage of pieces spoiled during the burn, through upsetting.

When ware is turned, the factors entering due to molds are eliminated. The main thing to be considered is the matter of section. There is a tendency for the designer to thicken a bushing abruptly in case he wishes a shoulder or ledge for clamping purposes. Thick walls and small central holes are a combination to be avoided if possible since it makes a difficult piece to dry, as the air cannot get at the inside of the walls and dry them as rapidly as it does the outside. Corrugations must not be too thin and deep, or cracking takes place due to too abrupt a difference in thickness of section.

Finally the longer the tube, and the smaller its diameter, the more difficulty there will be in drying and firing without warping. Then too, such a tube is difficult and costly to place in the kiln. If too long to stand on its base, it must be hung from a shoulder in case there is any, or by some other method. As a result there is a fairly certain loss of a portion of the tubes, due to warping during the burn.

| |||

| Fig. 4 — Casting Mould |

If the ware is to be cast, the designer has more leeway as to shape, since the molds are usually in sections. Fig. 4 gives a good idea of this. Here the main mold is in two halves, with a bottom piece and a core. This being the case it is readily seen that the outer surface need have no draft or slope, for instead of the insulator being dropped out of the mold, here the mold is taken away from the insulator. In case a core is used to form a hole in the center of the insulator, the more draft the better.

As the clay body goes into the mold in a liquid condition, and usually contains more water than an equal volume of jigger clay, the shrinkage is greater, and care must be exercised that corrugations or shoulders are not abrupt, or else the shrinkage will cause cracking before the mold can be removed. Once out of the mold, the drying and subsequent processes are exactly the same as in the case of the jiggered ware and the same factors enter.

| |||

| Fig. 5 — Dry Press Machine |

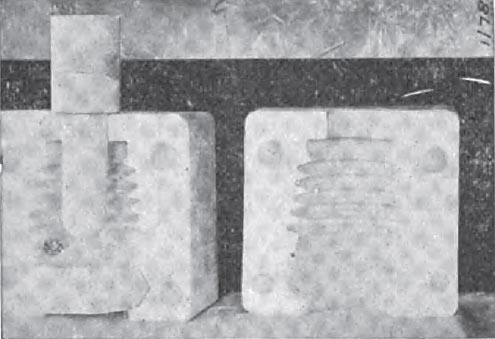

Since the dry process is radically different in its method of forming, the factors governing design are modified more or less all along the line. It will be remembered that the moisture content is low to begin with, approximately half of that of the jiggered ware, and the structure is more open and granular. A dry press machine is shown in operation in Fig. 5. The resemblance to the old fashioned printing press will be noted. Fig. 6 shows the two-piece die and a piece of burned ware formed by it. One part of the die is fixed in the lower part of the press. The other part is attached to a threaded bar and travels in a straight up-and-down motion as the bar is turned round.

| |||

| Fig. 6 — Dry Press Die and Fired Insulators |

It follows then, that the most effective pressure is the straight downward thrust, and hence any part of a piece which must be filled and packed by a lateral or angular thrust of the clay will be less compact in structure than that receiving the full down pressure. The designer must keep this fact before him constantly. Every hole, every projection must be studied from this angle. If all the rods for forming the holes can be put in vertically, well and good. All that is necessary then is to see that there is a slight draft to the rods so that the piece will lift out easily. In this case the ware will lift out with a single motion on the part of the workman.

If however, rods must run horizontally, trouble from cracking is likely, due to different rates of shrinking, since one part of the mass is more compact than the other. The clay above the rod and at the sides receives the direct pressure. Under the rods, however, the clay must flow in from the sides and be compacted by side thrust. Besides this, the operation is more costly, since the operator must slip these rods in place to start with, and then after forming the ware, slip them out before . the piece can be lifted clear of the die.

Once formed, the piece will generally stand a little rougher treatment in the subsequent processes than jiggered ware of like weight, because of the lower water content and more open structure. Of course the sudden thickening of a section is to be avoided, although it does not cause so much trouble as with the wet process. This also applies to sudden change of direction. The need for rounded edges and corners remains as in the case of the other ware, the glaze acting the same in both instances. In the firing of dry press ware, there is generally more trouble due to thin flat sections, which are liable to warp, than to inadequate setting surface, owing to the nature of the ware made by the dry process in general.

Considering all these factors which play a part in design by whatever process, one factor appears of much importance. This is the matter of thickness of section, or rather the change of thickness in a piece. A slight adjustment here or there will usually remedy the faults, but an abrupt thickening of the walls of an insulator usually means trouble.

(1) See article on "Electrical Porcelain" by the authors in the JOURNAL for Feb. and March 1918, pp. 36 and 77.