[Trade Journal]

Publication: Electrical Review

Chicago, IL, United States

vol. 77, no. 20, p. 721-724, col. 1-2

Features of European Insulator Testing Practice

Two-Part Insulators of Pin Type Prove Satisfactory for Service Below 70,000 Volts—Tests Are Made of Electrical and Mechanical Properties of Individual Parts and Complete Assembled Units

By B. SCHAPIRA

Stresses to which insulators are exposed in service are chiefly of a two-fold nature—mechanical and electrical. Consequently, insulators must be tested with both of these qualities in view, if the tests are expected to reveal their true service properties. The accompanying illustrations and descriptive matter will serve to show some of the detail of European testing practice as carried on in the Schomburg Works at Margarethenhutte, Germany.

| |||

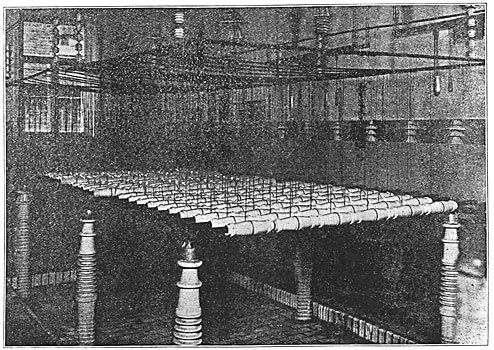

| High-Voltage Bushings Mounted on Racks for Indoor Testing. |

For working pressures up to about so,000 volts pin-type insulators are almost exclusively used, the kind used most extensively being known as the delta-hell type. An accompanying illustration shows the general character of an insulator of this particular kind. The two parts are made and baked separately and then are joined together by pure portland cement. Such construction has the advantage of allowing the use of thinner, and consequently more perfectly made, sections of porcelain. In addition, the two parts may lie separately tested, the combined testing voltage being much in excess of what would be allowed for an insulator of only one part. A one-piece insulator for 10,000-volt service would be tested with a pressure of from 35,000 to 40,000 volts, while the upper section alone of a delta-bell insulator would receive a test of 35,000 volts. The pin section of such an insulator would be tested with a pressure of 25,000 volts, giving a total puncture test of 60,000 volts for the two sections of porcelain. Moreover, the cement laid between the two sections aids in distributing the electrical stresses and so adds further to the safety of such construction. Disruptive tests of these insulators are made under oil, it being impossible to raise the pressure to the required point in air without spilling over. An average of about 110,000 volts is required to puncture a well made unit. The actual tests applied depend upon the working voltage and are shown in the accompanying tables.

| |||

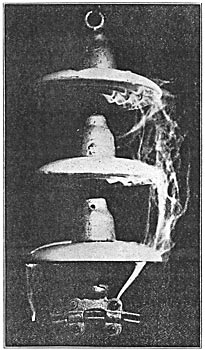

| Three-Part Suspension Insulator Undergoing Rain Test at 135,000 Volts. |

For insulators of 70,000-volt capacity three parts are cemented together, such construction allowing the extremely high testing voltage given in the table. Each insulator is tested for a period of 15 minutes unless punctured before this time. If a puncture takes place, the testing is continued for a further period until the piece in question is rejected or stands the test for the full prescribed period. It is evident that after passing such tests the electrical safety of an insulator is quite satisfactory, this being particularly so with one of low voltage rating. However, with increasing dimensions the safety coefficient of delta-bell insulators diminishes steadily, due to the sliding-spark phenomenon. Surface-discharge tension is not exactly proportional to the dimensions, and voltages are limited by this discharge pressure. Consequently, insulators of this type are not used on voltage above 70,000, the dimensions and weight becoming excessive above this limit. Suspension-type insulators are used, as a rule, for voltage of 50,000 or over.

|

Three large testing fields are used for routine work, one field being equipped with transformers for 100,000-volt testing and the others for 150,000 and 200,000-volt testing, these values in each case being maximums. Each field is' divided into two parts, one part being used for testing while the other section is being refitted with a new lot of insulators. The testing equipment for delta bells and other similar pieces consists of a large water basin covered over with a wooden top. Holes are made through the top of such size as to allow the inverted unit to extend into the water beyond its weakest point, that is, beyond the point of probable failure. Water is poured inside the inverted insulator and the transformer terminals are connected to the basin and to the inside of the various insulators. As many as 200 or more insulators may be tested in a single basin at one time by using an overhead bus system with brass chains to drop down for connection to each unit. Former practice of using acidulated water has been found useless as ordinary water is a sufficiently good conductor at the voltages used.

|

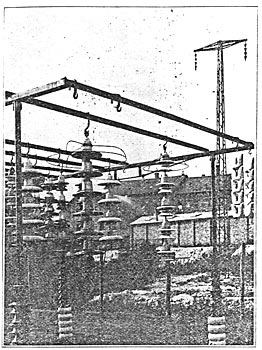

BUSHINGS TESTED IN LARGE LOTS ON SPECIAL PIPE SUPPORTS.

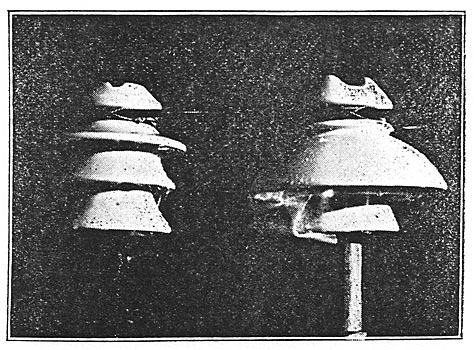

Bushings and insulators of a similar character are tested in a somewhat different manner. As may be seen from the illustration, bushings are slipped over metal pipes and arranged in large groups for testing. The supporting pipes are connected to one side of the testing transformers, and chains, as before, supply the connection from the outside of the bush to the transformer by means of a set of overhead buses. The voltage is raised slowly up to the point of surface discharge, it being the object to carry the test to a point where sparks appear. Such procedure, experience has proven, eliminates all defective pieces. As an evidence of quality each insulator is labeled with the testing voltage to which it was subjected. As stated before, further tests are made to determine punctures strength, the insulator being immersed in oil for this test. An accompanying table gives the disruptive strengths found for insulators of the delta-bell type. An accompanying illustration shows two types of delta-bell insulators being subjected to test under rain conditions. Rain tests are conducted with special laboratory equipment intended to produce conditions similar to those prevailing in actual outdoor service. Fog is imitated and rain of varying intensity and from various angles is projected into the insulator carrying a live wire tied into the working slot or notch. Surface-discharge voltages are shown in an accompanying table. A static wattmeter with a measuring transformer, for direct connection with the high' tension circuit, is used to measure actual losses during the period of surface discharge. These losses are not of 'great importance when compared with other transmission losses, but are much increased for a short period during the beginning of a heavy rain.

| |||

| Two Styles of Pin-Type Insulator Undergoing Rain Test. |

Mechanical strength is fully as important as good electrical qualities in insulators for high voltage. Greater spans, involving larger and larger mechanical strains, are being used to decrease the number of expensive supporting structures. Thorough baking at a temperature of 165o deg. C. produces porcelain of a quality hard and strong enough to resist any strains that may be applied to delta-bell insulators. The supporting pins are proportioned to bend over completely before the porcelain will fail. Tests of random samples are considered sufficient to prove the mechanical strength of a given lot of units.

|

Electrical tests are made following mechanical tests in order to detect invisible defect or damage that may have been produced by the strain. The test figures shown in an accompanying table represent conditions where insulators are fitted to their pins with hemp packing. Cement and similar binding substances give greater strength, but are not recommended for, the larger insulators because of the resultant restriction to the free expansion and contraction of the pin, binding material and insulator with changing temperature. The unavoidable consequences of such restrictions involve breaking of the insulator accompanied by interruptions of service and other undesirable difficulties.

|

| Outline and Section of Delta-Bell Insulator. |

| |||

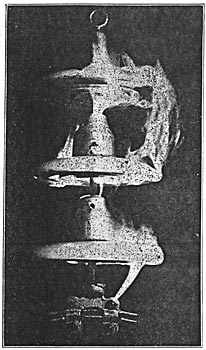

| Three-Part Suspension Insulator Being Tested With 230,000 Volts. |

As previously stated, insulators of the delta-bell type increase in size and weight more rapidly than in capacity, the 70,000-volt size being about five times as heavy as the 50,000-volt size. Suspension insulators, not being subjected to such variations, are more suitable for the higher voltages. However, because of the difference in the methods of supporting conductors, insulators of this type must be given more consideration from the mechanical point of view. Surface-discharge and puncture tests are made of the individual units of suspension insulators, the safety of this type as compared with pin-type insulators being quite high because of the number of units involved. Each individual part is tested up to its point of surface discharge, this being the highest voltage that can be obtained. The most important units of either suspension or strain insulators are subjected to tests of 80,000 volts. Since seven links are joined for a working pressure of 110,000 volts, the test strength of the entire string amounts to 560,000 volts. Following the electrical tests of the various parts metal fastenings are cemented in place, and mechanical testing follows the final setting of the cement. One mechanical testing device is arranged for routine work, all suspension-type insulators being subjected to a load of 6600 lbs. in this machine. Any link showing the slightest failure in this load test is rejected, and all others are labeled with the test data. Short electrical tests follow the mechanical test to detect any possible invisible damage.

|

| |||

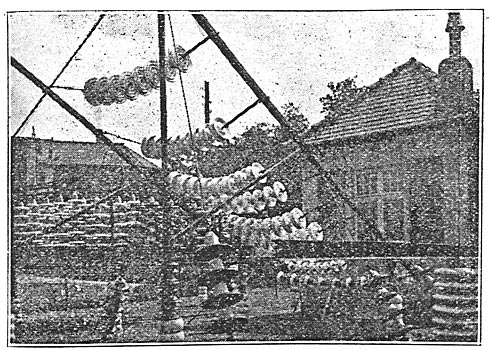

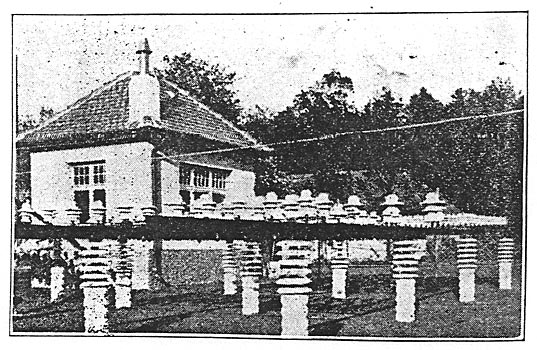

| Suspension Insulators on Outdoor Testing Rack. |

| |||

| Pin-Type Insulators on Outdoor Testing Racks. |

Random testing of units for disruptive strength under oil serves as a guide in the maintenance of quality of product, disruptive strengths as high as 150,000 volts per unit being developed in this test. Suspension units selected at random are assembled in strings and subjected to surface-discharge tests under conditions approximately those met in actual service. Accompanying illustrations show such a string of three units subjected to dry testing at 230,000 volts and to rain testing at 135,000 volts. A seven-link chain will have a discharge voltage of 470,000 volts when dry and of 250,000 volts when subjected to a rain test. To determine actual open-air characteristics of insulators, a 200,000-volt overhead line is used to transmit power to an outdoor testing field. This line itself, which is provided with short strings of suspension insulators, serves as test equipment as well as for conducting power to the regular field test. It is not uncommon for sparks to appear on the insulators of this line under unfavorable weather conditions. Accompanying illustrations show pin-type, suspension and strain insulators set up for test in this field. Experiments are carried on with these various units to bring about improvements in existing types and to develop new designs. Periodic testing about once a month determines variations in surface-discharge voltage, losses and surface resistance. These tests are conducted to determine probable performance throughout the life of the equipment. This test line and field is considered of great value since natural conditions are encountered in a manner which cannot be accurately reproduced in the laboratory. Observations in the testing field are greatly facilitated by the installation of suitable instruments and measuring devices in the house shown in the views of the test field.

| |||

| Suspension Insulators Showing Guard Rings at Each End of the Set. |