[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 16, p. 185-187, col. 1-2

Asphalt Emulsion Reduces

Insulator Radio Troubles

Treating head, tie wire groove and pinholes with insulating compound proves effective and practical way of minimizing radio interference.

By F. O. MCMILLAN

Research Professor in Electrical Engineering,

Oregon State College

LABORATORY tests at Oregon State College show that asphalt emulsion properly applied on the conventional types of high-voltage insulators, now in service, will very greatly reduce the radio interference they produce. The best results are obtained with asphalt emulsion, or any treatment applied for the purpose of eliminating radio interference from insulators, when care is exercised in the application of the material. The methods of application described below have been found satisfactory for treating the pinholes and heads of insulators.

Defective insulators, particularly those with one or more cracked shells or with loose cement between shells, are usually only slightly improved, if changed at all, by the application of asphalt emulsion or any other treatment. Therefore all insulators should be carefully inspected before treating and those that are found to be defective should be replaced with good units.

Treatment of insulator pinholes that are not equipped with metallic thimbles cemented in place is very important. Insulators with metallic thimbles carefully cemented in place do not usually cause very serious radio interference from electrical discharges in the pinholes at normal operating voltage. Malleable thimbles for fin. pin threads are in general better than the pressed metal thimbles for larger threads because the total diameter is smaller and the clearance between the metal and the porcelain of the insulator over the surface of the cement is greater, therefore the voltage gradient imposed on the air in that region is less. The sharp edges of pressed metal thimbles sometimes cause interference because of dielectric flux concentration and corona formation on them.

The radio interference characteristics of an insulator fitted with any type of metallic thimble is usually very much improved by carefully filling the pinhole with cement to a point flush with the end of the thimble. This precaution avoids a short air gap in the region of high dielectric flux density between the exposed end of the thimble and the surrounding porcelain shell. When the air in such a gap is not displaced with cement or some other compound it will cause radio interference at a comparatively low voltage.

Insulators with porcelain or glass threads that are not treated in any way to make the surface conducting cause very serious radio interference at very low voltage because of the electrical discharges accompanying the ionization of the air between the pin and the insulating material. For this reason insulators with threads formed in the untreated insulating material should not be used in locations where the elimination of radio interference is an important consideration. Pins with lead and various kinds of spring threads are not effective in eliminating the radio interference caused by such insulators because they do not displace all of the air in the pinhole between the pin and the insulating material, and at any given insulator voltage this gas is subjected to practically the same voltage gradient regardless of the construction of the pin.

| |||

| Fig. 1—Asphalt Emulsion Averts Radio Interference. After Fifteen Months Exposure to Weather and Rated Voltage the Luster of the Deposit is Dimmed, But the Corona-Forming Voltage is Not Found to Be Measurably Reduced. |

Displacing all of the air in the pinhole with an insulating compound that is dielectrically strong enough to withstand the maximum voltage gradient to which it is subjected in service eliminates the radio interference from that source. The air may be displaced by removing the insulator from the pin and carefully coating the entire surface of the pinhole and the threads of the pin with asphalt emulsion; a small excess of emulsion should be left in the pinhole to insure filling the voids; the insulator is then screwed home on the pin and the excess emulsion that is forced out around the pin removed.

Treatment of insulator heads in detail

The conductor and tie wire are removed from the insulator, the head wiped clean, the conductor and tie wire grooves coated with a thick layer of asphalt emulsion, the conductor coated with the material for a distance equal to slightly more than the length of the conductor groove in the insulator and then tied on the insulator with a very tight tie. This method of applying the treating material allows the conductor and tie wire to embed themselves in the asphalt emulsion and eliminate the thin air films in the dielectric field between the conducting materials and the insulator surface. The coating applied on the conductor where it is in contact with the insulator fills the voids between the cable strands and still further insures the elimination of gas inclusions in the regions of high-voltage gradient.

The ends of the tie wires are snipped off close to the conductor except when "live-line tools" are used or when for some other reason it is undesirable to cut the tie wire close to the conductor. In such instances the tie wire may be cut to length with the ends turned back in closed loops approximately 1 in. in diameter to prevent them forming corona-discharge points.

After the conductor is tied in place the entire head of the insulator is covered with a layer of asphalt emulsion, from A to i in. in thickness, and extending out on the top shell a distance of approximately if in. from the bottom of the tie wire groove. Particular care must be exercised to insure filling the conductor and tie wire grooves around and over the conductor and tie wire. An insulator treated with asphalt emulsion is shown in Fig. 1.

In areas where insulators are subjected to salt fog deposits, excessive contamination with dust, portland cement or other conducting or partially conducting materials the surface insulation resistance decreases to very low values. When insulators subjected to such conditions are treated with asphalt emulsion and the conductor and tie wire are entirely incased in the insulating material the asphalt coating over the tie wire is subjected to practically the entire conductor-to-pin voltage due to the insulator surface conduction. In the case of the higher-voltage insulators this voltage will puncture the asphalt. Since the asphalt is somewhat self-healing successive discharges through it will occur at intervals controlled by the insulator surface conditions. These discharges cause serious radio interference if permitted to occur, and when asphalt emulsion is used under conditions of serious insulator contamination it is recommended that tie wires of not less than No. 4 A.W.G. be used. After the normal insulator treatment is completed the emulsion should be scraped away to bare the outer surface of the tie wire in four places, from 1 to 2 in. long, equally spaced around the head of the insulator. Uncovering the tie wire in this manner permits the surface conduction to take place without puncturing the asphalt and it does not materially decrease the effectiveness of the treatment in eliminating the corona discharges between the tie wire, the conductor and the dielectric of the insulator.

An excellent grade of asphalt emulsion suitable for treating insulators can be purchased for 57 cents per gallon in 55-gal. drums. Approximately 1-pint of emulsion is required to treat a 66-kv. insulator, and allowing a 10 per cent waste during application the material cost is slightly less than 4 cents per insulator. The labor cost for applying the emulsion on the heads of insulators, from available data, is estimated to be 30 cents per insulator. In cases where the pin and pinhole must be treated the labor cost is estimated to be 10 cents additional per insulator. The total cost per insulator for labor and material is therefore approximately 34 cents for treating the head only and 44 cents for treating the head and pinhole. These labor cost estimates are considered to be maximum values and it is believed that skilled workmen, after gaining some experience, will very materially reduce the labor items below the values given.

Tests show success of treatment

The laboratory tests on asphalt emulsion were made on treated insulators, half of which were equipped with 20-in. sections of aluminum cable steel reinforced and aluminum tie wires and half with 20-in. sections of copper conductor and tie wires. The test specimens were prepared in this manner to preserve the treatment and make it possible to take the insulators directly from the radio interference tests to the life tests without retreating them. Both aluminum and copper conductors and tie wires were used because it was necessary to determine from the weathering tests whether the conductor and tie wire material had any influence on the life of the compound. The insulator samples used were treated on the head only because they had metal thimbles cemented in the pinholes and were therefore fairly free from corona at the pin.

An investigation of the visible corona on treated insulators showed that those treated with asphalt emulsion had higher corona-formation voltages than any of those treated with the many other kinds of materials investigated and in every instance the corona formed at some other point on these insulators before it formed on the head where the asphalt emulsion was applied.

Cathode-ray oscillograms were taken of the corona current for 66-kv. porcelain insulators of conventional design both with and without asphalt emulsion treatment to determine in a quantitative way the effectiveness of this treatment for preventing corona discharges on insulators and eliminating the resulting radio interference. The electrical circuit used in taking the oscillograms was a bridge type developed to eliminate the charging current from the corona current measurements and its use makes it possible to either visually observe or photographically record the corona current independent of the insulator charging current.

| |||

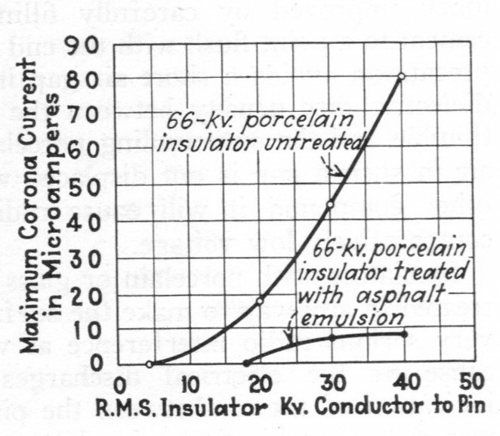

| Fig. 2—Corona Current Cut 90 Per Cent by Asphalt Coating. 66-Kv. Insulators With 40-Kv. R.M.S. Applied Conductor to Pin at 19 Deg. C and 3.8 Per Cent Relative Humidity. |

The cathode-ray oscillograms in Fig. 2 show the corona current for a 66-kv. porcelain insulator without treatment and for the same type of insulator with asphalt-emulsion treatment at r.m.s. conductor to pin potentials of 10, 20, 30 and 40 kv. (The equivalent three-phase line voltages are 17.3, 34.6, 52, and 69.3 kv.) These oscillograms show the very marked reduction in corona current effected by the application of asphalt-emulsion treatment.

|

| Fig. 3—Corona-Forming Voltage Raised Materially and Current Substantially Reduced |

Data were obtained from the cathode-ray oscillograms shown in Fig. 2 for plotting the maximum corona current in microamperes as a function of the insulator voltage for both the untreated and the asphalt-emulsion treated insulators. The graphs in Fig. 3 show that the asphalt-emulsion treatment on the head of the insulator reduced the maximum corona current to 10 per cent of the value obtained with the untreated insulator. These results are pessimistic rather than optimistic, because a large part of the corona current that remained after the head of insulator was treated was due to corona around the metal thimble in the pinhole where no treatment was applied.

This fact is confirmed by observations which showed that corona occurred around the thimble in the pinhole of the treated insulator at 18 kv., which is 20 kv. below normal operating voltage. The treated insulator used for the comparative measurements of the corona current with the cathode-ray oscillograph was selected because it had the lowest corona-formation voltage, on both the head and in the pinhole, of all the insulators treated with asphalt emulsion and therefore the results obtained represent the minimum improvement to be expected from this treatment.

Radio interference measurements made with a Western Electric field strength measuring set indicate that the asphalt-emulsion treatment reduces the radio interference produced by a 66-kv. insulator, at normal operating voltage, to a value ranging between 3 and 10 per cent of that produced by an untreated insulator of the same type. These measurements show that asphalt emulsion is very effective in mitigating the radio interference from high-voltage insulators.

Life tests are in progress on various kinds of materials that show promise of proving valuable for treating insulators in service.

Six power companies in various parts of the United States have either already treated the insulators on some high-voltage lines or will in the very near future. One of these companies is on the Atlantic seaboard, two are on the Pacific and three are inland in regions of different climatic conditions. Valuable data on asphalt-emulsion insulator treatment should, therefore, soon be available from actual service under widely different climatic conditions.