[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. XXII, no. 437, p. 265-266

POWER TRANSMISSION

THE NEVADA COUNTY (CAL.) ELECTRIC POWER CO.

|

A little more than one year ago work was commenced on the plant of the Nevada County Electric Power Company. Today it is giving twenty-four hour service to 3,400 incandescent lamps and 32 horse-power in motors, with contracts ahead for 450 horse-power in synchronous motors. The plant has been in operation since Feb. 5, and has given commercial service from the start. Till June 12 the service extended from 4:30 p.m. to 9 a.m.; since that date the plant has been in continuous operation.

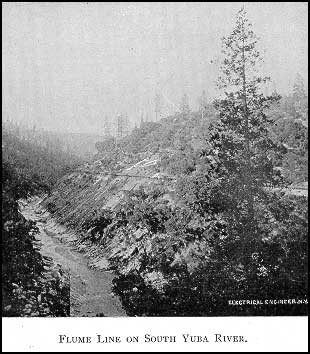

On the South Yuba River, 1-1/2 miles above Purdou's bridge, is built a log crib dam, 28 feet high and 150 feet on the crest, which diverts water to the flume 6 feet wide and 5 feet high, which with a grade of 10 feet per mile follows the windings of the canyon for 18,000 feet. The rugged nature of the country and the difficulty of the work is well shown by the accompanying engravings.

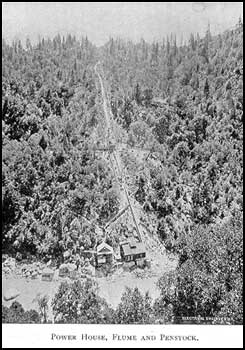

At the end of the flume a head of 206 feet is attained and the water is carried to Pelton wheels through 300 feet of 48-inch, 44-inch and 42-inch pipe, giving in round numbers about 2,500 horse-power.

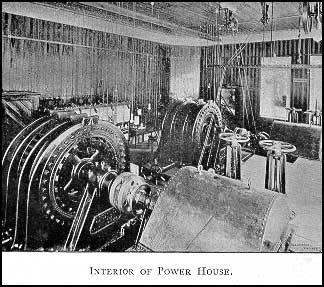

The power house is a stone, wood and corrugated iron building, 28 feet by 40 feet, having one large room with 20-foot ceiling, in which are installed at present two 340 kilowatt Stanley two-phase, 5,000 or 2,500 volt generators connected by special insulating couplings, shown clearly in the engravings, to two 34-inch Pelton wheels running at 400 revolutions per minute; two Crocker-Wheeler 5 kilowatt bipolar exciters belted to two No. 5 Pelton motors; one No. 3 Pelton motor running at a consistent speed to drive the differential governors; and a suitable switchboard.

|

Current is delivered in the line at 5,000 volts direct from the generators, saving the loss of power and extra complication of step-up transformers. It may be of interest to note that there has not been a moment's trouble with, or the least item of repairs to, the generators thus far.

|

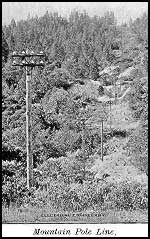

The pole line is very substantial and carries two complete circuits of four wires each on triple petticoat porcelain insulators. No. 3 bare copper wire is run to a point 4 miles from the power house where the circuits branch. No. 6 bare copper is run from here one mile to Nevada City, and four miles to Grass Valley. In both towns all wire is insulated.

A No. 6 iron wire, run on the tops of the poles and grounded at every other pole, was intended to protect the system from lightning, but it has been found entirely inadequate and Wurts non-arcing metal arrestors have been installed at the power house and at the terminals of all branches.

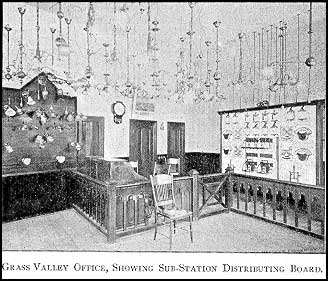

At both towns sub-stations have been established with elaborate switchboards and step-down transformers which reduce the line pressure to 2,000 volts for lighting and small power distribution. There are furnished now 1,600 incandescent house lights, 58 25-candle-power series incandescent street lights and four alternate current arcs in Nevada City; and 1,800 incandescent house lights and 40 arcs for street lighting in Grass Valley.

The motor business is very promising, but mining men are slow to adopt the new power till they see it in successful operation elsewhere. The first mine to adopt electricity for both lighting and power near Nevada City was the Red Hill, Limited, which is using a 30 horse-power Stanley two-phase induction motor to drive a Griffin mill, which has been running successfully since June 12. The second installed was a 2 horse-power Stanley two-phase induction motor for driving a concentrator and pump working the tailings from a large mine, and has been in almost constant service since the latter part of June. The third motor to be installed is a 120 kilowatt synchronous motor to drive an air compressor at the Gold Hill mine, near Grass Valley, where it was decided to use compressed air in order to utilize the engines already installed; it is also intended to use the steam boiler already in place as a receiver and reheater as well as reserve in case of accident to the electric machinery; this motor will start up in a few days.

|

For about three months it was necessary to run at 2,000 volts, which was very easily accomplished by changing the connections on the generators and cutting out the step-down transformers. With this arrangement, however, it was found difficult to keep the phases balanced, but it was accomplished very well by means of an iron wire inductive resistance. Since changing back to 5,000 volts no trouble has been experienced with unbalanced phases, and the difference in voltage between the two towns has been very little, even when the heaviest load is in, in fact it is often two volts higher (on the 100 volt circuits) at Grass Valley than at Nevada City.

|

One hundred volt 3.6-watt lamps are used exclusively for house lighting and the Edison base has been adopted as standard for them. For the few 50 volt lamps it is necessary to use the Thomson-Houston base has been adopted. The accompanying diagram shows the load curve as taken from the power house reports of August 6.

|

| Nevada Power Plant Load Curve. |

The conception of the plant is entirely due to the superintendent, Mr. A. Fregidgo, and the success of the enterprise is due to the energy and ability of the general manager, Mr. E. J. de Salba, Jr. The consulting engineers for the installation were Messrs. Hasson & Hunt and Mr. W. R. Eckert, of San Francisco. The machinery was installed by Mr. Jno. Martin, Pacific Coast agent for the Stanley Electric Manufacturing Company, who were represented in the field by Mr. E. E. Stack. The electrical portion of the plant since starting has been under the direction of Mr. L. M. Hancock.