[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 14, no. 223, p. 143-145

THE MAKING OF LAVA INSULATORS AT CHATTANOOGA, TENN.

Lava insulators have won a distinct place in the electrical arts in this country, and each year sees some new application of this interesting form of insulation, wherever exacting conditions with fire and moisture have to be contended against. Lava seems to be equal to glass, porcelain and mica in its ability to withstand considerable electrical strain, while it lends itself readily to manipulation into an immense variety of shapes, especially for small parts of apparatus. It can be turned, cut or molded into any shape required, before being submitted to the hardening process, and so little susceptible is it to warping while going through the treatment for hardening that it will fit into any given place for which it was designed with the accuracy of brass or other metal. This fact offsets, or, rather, emphasizes the other quality it has of extreme hardness, as the result of which its bearing parts, or its threads, in any apparatus, remain for an indefinite time without perceptible wear; so that while other portions of the machine or instrument may need renewal, the details made in "lava" may be employed over and over again. "Lava" is not soluble in any known acid, it is waterproof and non-absorbent, and it is absolutely resistant of heat. Any ordinary temperature that may be met with, where the parts are in contact with fire, does not hurt it in the least. The writer has seen pieces that have stood a continuous exposure of thirty hours surrounding a 2,000 c. p. arc, being part of the time practically in the arc; yet the impression, if any, made on the rings used was really undiscoverable. The insulation resistance is also extremely high. A piece of about a cubic inch tested by the Thomson-Houston Electric Co., who have used enormous quantities of lava, is reported to have shown a resistance of 50 megohms.

| |||

| Machine Work in Insulator Department. |

It is natural that with the qualities roughly outlined above, "lava insulation" should have made its way in the electrical field since its introduction a few years ago. At the present time the consumption is very large, as many as half a million pieces have been ordered in a single week. There are one or two substances that have renewed in electric lighting work a popularity already won in the domain of gas, and lava has certainly been among them. The number of lava gas tips in use now runs up into millions, and so long as is used there is no reason to doubt that the demand will grown.

| |||

| Part of the Mill Room. — Grinding Steatite. |

The basis of "lava" is steatite or soapstone, of which the lava manufacturers D. M. Steward & Co., of Chattanooga, Tenn., have a remarkably fine mine. The same material is worked up into the millions of dustless crayons and slate pencils used in this country every year, and hence is a standard article of diet not only with the savages of South America, but with the gentle school children of North America. Before establishing himself in Tennessee, where he is near his source of supply of raw material, Mr. D. M. Steward carried on his industry for several years at Cincinnati. It is a singular fact, and one that tells volumes of the changed social and industrial conditions of the New South, now so warm in its welcome to manufacturing enterprise, that when he removed from Cincinnati, Mr. Steward, an old Union soldier, built his factory on the very ground where he had camped and bivouacked during the struggles of the civil war. The people with whom he had fought were not less glad to extend him the hand of comradeship than was he to settle among them as a citizen, with his energy, capital and experience. Perhaps if Mr. Steward had not gone fighting through Tennessee he would never have known what a Land of Promise awaited in the South when the piping times of peace could come around again.

| |||

| Cutting Blanks for the Lathes. |

Taking the crude steatite as it arrives from the deposits in the mine - a pinky-white rock, soft and smooth to the touch like polished wood, or plumbago - it is first necessary to reduce it to powder. In the large factory of which a view is given in our illustrations, Mr. Steward has a complete equipment for this and all the subsequent stages of the work. The rock is ground to powder by passing it through an ordinary stamp mill, of the kind familiar in mining regions. The powder is then carried by chain conveyer to the mills proper. Here it is ground exceeding small, so that one can hardly feel it when rubbing it between the fingers. This second powder, to which the word "impalpable" might be fairly applied, is then conveyed by elevators to the bolts, where it passes through the finest silk bolting cloth. From these bolts it is deposited in large bins or settling chests, whence it falls to the lower floors again. It is taken from the receptacles and placed in revolving tubs, where the mass is treated with liquid chemicals which reduce it to a condition in which it resembles bread dough, and is so little American that it is entirely and absolutely free from grit. Leaving the mixers, it is passed to the rolls, where it is repeatedly pressed, and it is again pressed in special machines, operating under great hydraulic pressure, in which the dies are placed for turning out the blanks for the lava insulators. The dies are changed in the hydraulic press from time to time, in keeping with the size or class of insulator to be made. In many instances, of course, the pieces require careful and expert cutting and working, as illustrated in our engravings, so that they may be finished. The smallest of the holes that can be made in the "lava" and the fineness of the thread, are something remarkable.

|

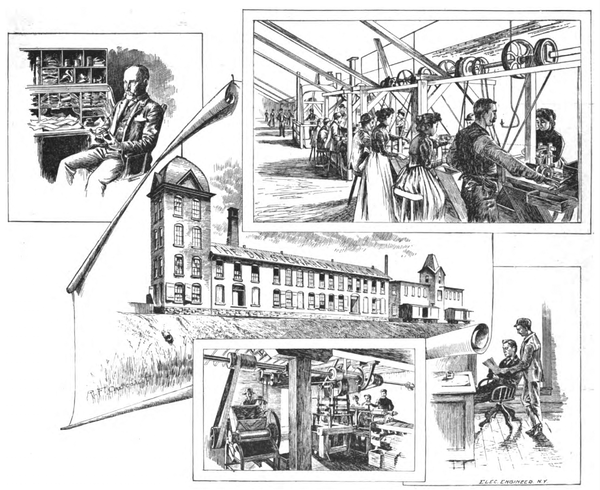

| Views at the Factory of D. M. Stewart & Co., Chattanooga, Tenn. |

After the sawn or pressed pieces have been prepared, they are subjected to the hardening process, by being placed in a kiln into which superheated steam is introduced in pipes, the temperature being regulated by the requirements of the article subjected to its influence. On leaving the kiln, the articles are examined, finished and packed.

Where the work is of such variety as in the case of lava insulators, the details of the process are many, though they do not greatly differ, the one end being uniformly and accuracy. Some of the pieces made are extremely small, others are quite large, and the range extends all the way from rings and washers, and cores for little magnets, up to long tubes for interior and underground work, and insulators for overhead trolley wires. Mr. Steward and his two sons, G. C. Steward, assistant manager, and Clarence S. Steward, superintendent, who superintended the work, have incessant inquiries for insulators which are intended and expected to stand the severest possible tests and to come out of the fiercest ordeal as fresh and smiling as the Hebrew youths of old from their bath of fire.

In view of the conditions that prevail in the South, with its equable climate, cheap labor, and nearness to iron and coal, it is somewhat singular that so little electrical manufacturing has been done in that region. But it is cause for congratulation that Mr. Steward, as an old Northern manufacturer, has been able to transplant his important industry and carry on there with renewed and growing success his production of a very interesting and useful detail of electrical work.

The buildings have a combined frontage of 450 feet. About 25 tons of material is used every week.