[Trade Journal]

Publication: Journal of the Society of Telegraph Engineers

London, England

vol. 5, no. 14, p. 249-252, col. 1

THE POROSITY OF DEFECTIVE INSULATORS.

Various experiments made by the Indian Telegraph Department have shown that when an insulator is electrically worthless, although perfect as far as the eye can judge, this defect is caused by the existance of extremely fine pores extending right through the porcelain, and ordinarily containing moisture. It is of the utmost importance that all such defective ones should be eliminated before any batch of insulators is employed in the construction of a line: To do this all the insulators are placed in an inverted position in water and water is poured into the porcelain cups, the water in each case reaching to within a. short distance of the rims; the resistance from the water inside to the water outside the porcelain cup is then measured.

Now in the case of first-rate insulators, such as those of Messrs. Shonberg of Berlin, the resistance of even the bad specimens, that is those to be rejected, is often very great. If the rim of a good insulator is slightly damp it will appear to be a bad one, therefore the rjms of all the insulators are artificially dried before the testing. In England the rims are dried by running red hot rollers along the top of the insulator trough. If the rollers are not hot enough or not kept long enough over the trough the rims are not dried; if too hot, or allowed to remain too long, the water begins to evaporate, and on removing the roller there is frequently a deposit of damp on the rim of the insulator. All this renders quantitative insulator testing a tedious operation.

Now it occurred to us that it might be possible mechanically to enlarge the pores of bad insulators so as to diminish their resistance, and so greatly to facilitate their detection. We selected two insulators made at Hizen in the south of Japan, one of them known to be good and the other bad. The resistance of each insulator was measured before and after each of the following processes by the loss of charge method, using a Thomson's Quadrant Electrometer and a Condenser, whose capacity was one-third of a farad, the edge of the porcelain cups being in each case very carefully dried.

First. The poles of a powerful Ruhmkorff's coil were attached to the outside and inside of each insulator in succession; and the primary current from a Grove's battery kept on for about six minutes, the hammer of the coil oscillating so as to make and break the primary current with great rapidity during the time. The good insulator was unaffected, but the resistance of the bad one was reduced to less than one-halt

Secondly. Both insulators were soaked for several days in a saturated solution of copper sulphate, then taken out and left to dry so as to allow the copper sulphate, by crystallizing in the pores of the bad insulator, to enlarge them; the soaking and drying were repeated, and they were then soaked in fresh water for some time. The good insulator was still unaffected; the resistance of the bad one was reduced to one fourth its original value.

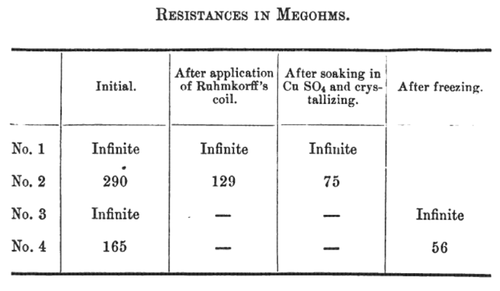

Thirdly. Two other insulators, one known to be good and me bad, after being soaked in 'ordinary water, were kept at a temperature of about 10° C. for fourteen hours by means of a freezing mixture, then soaked in lukewarm water for three hours, again frozen and soaked in ordinary water. The good insulator was unaffected, the resistance of the bad one was reduced to one-third. The following table shows the resistance of the four insulators under the various circumstances.

|

Infinite resistance means that the insulator retained a positive or negative charge for several minutes without any perceptible loss.

Since connection with the outside of the insulator is made by means of a copper wire placed in the water of the trough, and with the inside by a copper wire attached to the iron stalk! We have two different metals, copper and iron, separated by the partially conducting porcelain; the insulator, therefore, acts as a simple cell, and we are enabled to measure its resistance in two distinct ways. (1.) By giving an independent charge from a Daniell's cell and taking time readings with the electrometer as the charge is lost, using as the zero the reading when there is no further loss. (2.) Taking time readings on insulation after short circuiting, as the insulator's own electromotive force causes the copper wire attached to the iron stalk to acquire a negative potential relative to the copper wire attached to the outside of the insulator. In both cases we must calculate the resistance after a certain time has elapsed, when the ratios between successive readings at equal intervals of time have become equal.

We are inclined to think that a sudden cooling of porcelain insulators from some moderately high temperature, which might be determined by experiment in the manufactory, would so entirely destroy the insulation of bad specimens that they might be separated from the good with great facility. Such a process could most readily be carried out by the manufacturers. The authors of this paper have at present no opportunity of practically testing at a manufactory the importance of their suggestion. The experiments, however, described in this communication prove conclusively that the minute fissures in bad insulators may be artificially enlarged. It is easy also to see how the fact that bad insulators act as simple voltaic cells may be employed in separating them from good ones.

J. PERRY. W. E. AYRTON.

The Imperial College of Engineering, Tokei, Japan.