[Trade Journal]

Publication: American Electrician

New York, NY, United States

vol. 11, no. 4, p. 199, col. 1-2

HIGH TENSION INSULATORS.

The merits of defects of the porcelain insulator have been well shown up by the experience obtained with it during the last two or three years. The most recent designs show great improvements in overcoming the disadvantages of the earlier types.

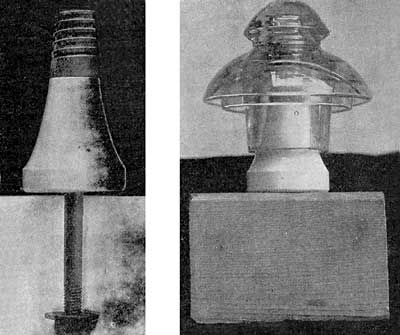

The accompanying illustrations show the meritorious details of the insulators manufactured by Fred M. Locke, of Victor, N. Y. In order to avoid the strains brought about while cooling through unequal shrinkage of parts of different thickness these insulators are made up of two or three shells, one for each petticoat.

| |||

| An Iron Pin With Wooden Top, Porcelain Base and Glass Insulator. |

The cut shows the pin on which the insulator is mounted. It consists of a 1/2 in. galvanized steel bolt with a screw threaded top of wood boiled in paraffine, and a base of porcelain, which extends well up within the inner petticoat of the insulator and increases greatly the arcing distance between the rim of the insulator and the pin, preventing the destructive arcing and consequent burning off of pins, cross-arms, etc., and increasing greatly the voltage which may be carried on the lines.

There is also shown a glass insulator with eaves to carry the water away from the cross arm and a long inner petticoat coming well down over the porcelain base just described. This is designed for 25,000 volts, its diameter being 5-1/2 ins. and weight 3 pounds. Another glass insulator 7 ins. in diameter weighing 5 pounds is put out for potentials from 22,000 to 50,000 volts.