[Trade Journal]

Publication: American Electrician

New York, NY, United States

vol. 11, no. 8, p. 399, col. 2-3

PORCELAIN AND CLAY INSULATORS.

The making of porcelain is one of the oldest arts that has come down from prehistoric time. For many ages it was regarded as a lost art, but modern ingenuity has solved the mystery and to-day the making of porcelain wares for both table and ornamental purposes, as well as for electrical uses, is a growing business in this country. Not only porcelain, but some grades of native clay are suitable for insulating purposes, the latter being almost as valuable as the former, in fact, fully as good in insulating properties, but not so attractive in appearance. One of the extensive manufacturers of this class of goods is the Akron Smoking Pipe Company, whose works are located at Mogadore, Ohio. This company has control of clay deposits which are particularly adapted to the manufacture of insulating appliances, including special devices, such as switch bases, lamp socket parts or other forms which are designed to serve as non-conductors of electricity. The output includes tubes, ranging from 5/16 inches inside diameter to 2-1/2 inches, and in length from 1 to 36 inches, as well as special shapes.

| |||

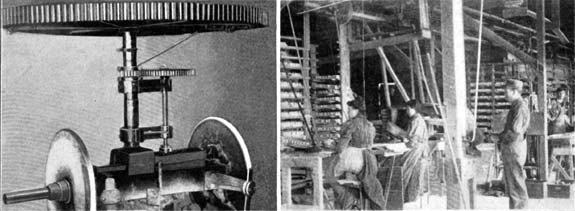

| Scenes in the Making of Porcelain and Clay Insulators. |

In the process of manufacture the clays are prepared by a washing process which removes all the foreign matter, including the iron oxides which are found in most clays and detrimental to the insulating qualities. After being washed the material is placed in what is known as a wet pan, which consists of a circular bed plate of iron with heavy wheels or mullers revolving upon it, and in this the material is pulverized and tempered until it receives adhesive dualities sufficient for molecular action to take place. It is now ready for the moulding process and is formed in dies or presses into electrical devices of all conceivable shapes and designs.

The forms after they are moulded are carefully placed on trays or dryers and placed on racks in the steam drying department, where they remain until all the moisture is evaporated, when the pieces are carefuly [sic] carefully inspected or trimmed and finished and are passed on to the glazing department. After the pieces have been immersed in the glazing solution they are again dried and packed in seggers and made ready for the firing process. The seggers are cylindrical shaped forms, which are made in the works from the best of fire clay, and are manufactured on a pottery wheel, such as is employed for making ordinary stone ware. The object of their use is to protect the goods from the action of the flame in the process of baking, and being filled they are placed in tiers in kilns until they occupy the entire space.

The process of firing requires about seventy hours, during which time the contents of the kiln are raised to a heat of about 3600° F. This process fuses the silicates into the pores of the clay and also the glazing material, while it changes the chemical composition and produces the most durable substance known or found in nature. The kiln goes through a slow cooling process after the fires are withdrawn and the goods are not removed until the temperature is again normal.

It is a practice with the company to have samples of its goods frequently tested by the electricians of the Board of Fire Underwriters, and its cheapest grades of clays have stood the tests of immersion in water for 100 hours without absorbing more than 73/1000 of their weight of moisture. This, as will be noted, is well within the limit of 1 per cent., the limit allowed by the Board of Fire Underwriters.