[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 48, no. 25, p. 1194-6, col. 1-2

Present Status of European Practice in Trans?

mission Line Work.

The problems of transmission of electrical energy over long distances by means of overhead conductors have received the close attention of Swiss and Italian engineers from the earliest days of electrical engineering, and the following brief notes of their latest practice may be of interest to American engineers who are facing similar problems, some of which can be theoretically solved, but a large number of which must find their solution by the, method of trial and error.

The experiences of Mr. Charles Brown, one of the earliest workers in this field, the inventor of the horn-type lightning arrester and a pioneer of many of the more recent developments, are always of interest. He gives a word of warning to those engaged in insulator testing, claiming that most insulators have a very pronounced fatigue effect. Though an insulator may stand a given tension for is minutes, it may possibly break down at this tension if it is maintained for two hours, and he recalls the great difficulty always experienced in attempts to deduce reliable results from any testing, except actual use on the transmission line.

|

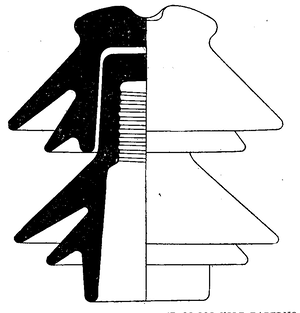

| Fig. 1 -- Insulators Used on the 30,000-Volt Paderno Transmission Line. |

He further states that very little trouble is experienced from heavy rain storms or climatic conditions causing insulator breakdowns, the trouble being almost entirely mechanical and due to lightning. Such mechanical defects as have been experienced are thought to be due largely to the use of cement for connecting the petticoats of the insulators together, since great difficulty is experienced in obtaining a cement which does not swell with increase of temperature and thus fracture the insulator. In Switzerland use is made of sulphur cement (when sulphur is used, the pins must be galvanized) and plaster of Paris, both of which have given satisfaction. The latter, however, being somewhat porous, must be varnished with shellac wherever it is exposed to the air at the outside of joints, etc.

|

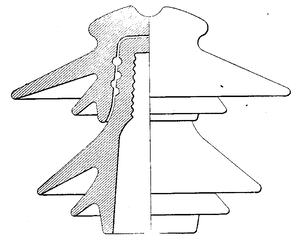

| Fig. 2 -- Paderno Type of Insulator Recommended for 40,000 to 50,000 Volts. |

For fixing the pins of the insulators, tow or hemp is used which is twisted around the end of the pin, the whole being then dipped in asphalt or shellac and screwed into the insulator. Mr. Brown states that no splitting or fracturing of insulators occurs with this method of fixing the pins.

It is further stated that no good results have been obtained with the Fox cement, which is thought to have too high a coefficient of expansion, producing splitting troubles. In this connection, however, it should be noted that somewhat thinner insulators are used in Switzerland than in Italy, and the engineers of the latter country have found very little trouble due to this cause.

As long ago as 1887 the Brown-Boveri Company first tried "guard wires" on the Burgenstock line, placing a single wire above the transmission line because it was then considered that the top wires were the most affected. Lightning then began to affect the lower wires, so the guard wires were discarded, and generally speaking they are not at present favored in Switzerland.

In general the position in Switzerland is one of doubt, and it is not unusual to find a enormous variety of lightning arresters and lightning-arrester devices placed on the transmission line, partly because practice has shown that better protection than by one single system, is secured by the simultaneous use of different systems of lightning arresters on the same line, and partly in the hope that a more close study of their behavior will give valuable evidence.

Mr. Charles Brown has expressed himself as very pessimistic at present and considers that no thoroughly satisfactory arrester is yet on the market; but he holds at present in greatest favor the "Horn" type, the "Wurts" type and the "water jet" type. This latter is stated to be much in favor in Switzerland and is being widely used now; but since several of these jets must be used on a given system and each one may absorb from 10 to 20 kw, it is a matter for careful consideration before installation.

|

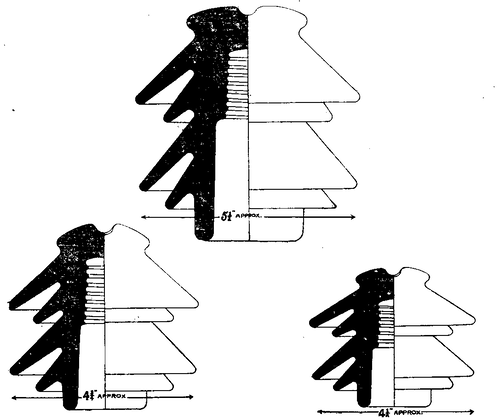

| Fig. 3 -- Modern Italian Insulators of the Paderno Type. |

Trouble has been experienced due to dynamic shock shattering the wooden poles and insulators. It is ascribed to the presence of water underground and has been overcome by moving the transmission lines some distance to either side of the spot affected. Other Swiss experts have referred to the difficulty in the manufacture of perfect insulators, pointing out that minute ii holes in the enamel in the surface which can not be seen by the eye, may pass test, and then cause breakdown after some months' installation.

Some again claim to have overcome the difficulty due to insulator splitting, by using no cement at all, the insulator being made in two or more pieces which are tested independently and then screwed together and the whole rebaked.

They have also paid considerable attention to the exact shaping of the edges of the insulator petticoats, a rounded edge being considered very bad, since in a heavy rain storm it will cause water to run under and drop on the surface of the lower petticoats. They at present very much favor a petticoat slightly turned up near the edge to check the velocity of the running water and then dropping to a sharp point on the extreme edge, which seems to prevent this running under. By this means it is considered that the effect of rain storms may be considerably reduced. For all transmission lines for electromotive forces of 40,000 volts and above, iron poles are preferred and if the insulators have not lore than two petticoats, wooden cross beams are used; if three or more, then they are placed directly on the iron poles.

|

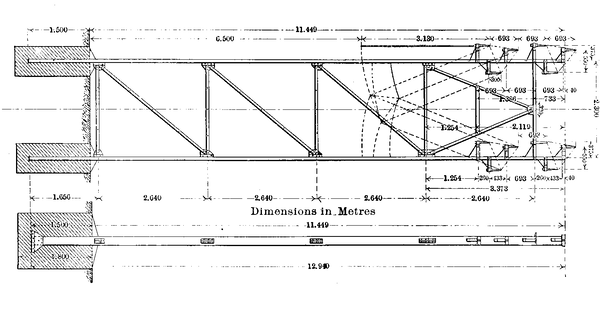

| Fig. 4 -- Steel Pole Used on Trezzo 15,000-Volt Transmission Line (Dimensions in Metres). |

In Italy, Mr. Guido Semenza, whose name is associated with he well-known Paderno transmission and with numerous others throughout the country, referring to his earlier experiences, stated that on the Paderno line, after some experiment, his conical type of insulator was chosen and a triple petticoat used, the line being, however, finally completed with two of these cemented together as one six-petticoat insulator. The dimensions of this were, height over all, seven inches; diameter of petticoat, 6-3/4 inches (Fig. 1). In other plants the Paderno type was then superseded by a much lighter insulator, but it has lately returned in favor and is in general use.

The actual Paderno insulator is shown in Figs. I and 2 and the Elect of this type on Italian insulators is illustrated by Fig. 3, which shows sectional view of insulators considered standard for 6,000 volts, 8,000 volts, and 12,000 volts.

The actual trial on a transmission line of the new Semenza insulator, recently described in these columns, is being looked forward to with great interest, as it is anticipated that it will a widely used.

The mechanical splitting of double or triple insulators, due to the expansion of the cement used in joining them together, has at been experienced, but it is probable that this is due to the use of a thicker and stronger insulator than employed in Switzerland. The cement used in connecting the petticoats together is generally composed of 10 parts of litharge and one part of glycerin.

Mr. Semenza considers that the problems connected with lighting troubles are not by any means solved. He has recently favored the Westinghouse low-equivalent arrester, Italian practice being at present somewhat against the use of any arrester which allows the arc discharge to be formed and then blows it out, since it is considered to tend to the production of serious surges.

With regard to the lightning discharges which produce shattering of wooden poles and insulators, this trouble has not occurred in Italy, since iron poles are used with this idea in view as one of their advantages.

Clipping of the petticoat rims of insulators has been experienced, but apparently does not materially affect their value. The greatest lightning trouble has been experienced from inductive discharges caused by lightning striking trees or nearby objects, since such a discharge sets up induced surges in the transmission line which cause flash-overs at the resonance points, thus short-circuiting the line and frequently cutting the rims of the insulator petticoats.

|

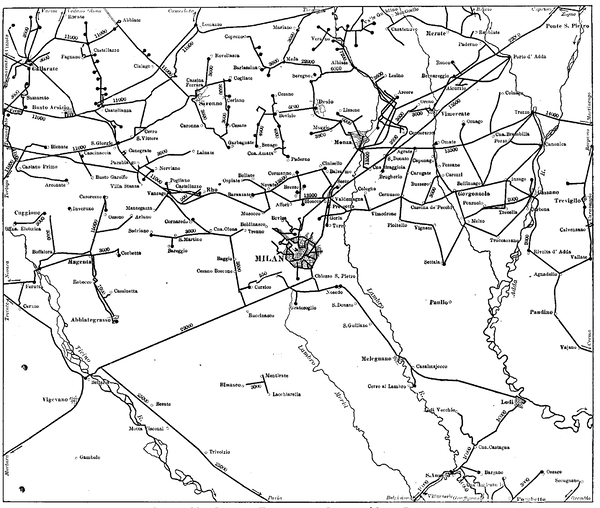

| Fig. 5 -- Map Showing Transmission Lines in Milan District. |

It is stated that some lines have given trouble due to the design of the line giving an inductance and capacity tending to produce certain resonance conditions at various points. This has been partially overcome by adding at several points new lightning arresters, and some experiments are now being made with special condensers placed at different points.

With reference to guard wires, it is interesting to note that in general, the fear of mechanical troubles has prevented their use in northern Italy.

The arrangement of the wires so that the arcs through which they swing, when moved by wind, do not interfere, has received much attention and when the triangular arrangement is used, the method shown in Fig. 4 is employed, which shows the conductors situated at the points of an equilateral triangle in which the base line is not horizontal. This figure also shows one of the standard iron poles used on the latest installation at Tretzo.

Engineer Semenza now uses a 119-metre span for general work and a 280-metre span is the longest he has used for isolated cases, such as bridging rivers, etc.

Fig. 5 was drawn from a map made especially for the balloon and air ship trials in connection with the Milan Exhibition in order that the aeronaut might avoid the danger of grappling irons coming in contact with the transmission lines, and gives an interesting idea of the dense network of transmission lines in northern Italy. From this map will be seen the rapid growth of transmission line work in Italy and will explain to some extent the rapid growth of such firms as Messrs. Richard-Ginori and Messrs. Pirelli, of Milan, who deal so largely with insulating materials.

While touching the subject of transmission of power in northern Italy, it is worth noting that practically no case whatsoever of hunting of alternators, when operated in parallel, has occurred there, and Italian engineers speak with astonishment at the references in the American technical press of a trouble practically unknown to them. Enquiry leads to the belief that the percentage line losses are about the same as those employed in America, but the absence of these troubles is frequently due to the remarkable pitch of perfection to which both engine and water turbine governors have been brought. In this connection, it may be of interest to recall that the standard frequency in northern Italy is 42-1/2 cycles.