[Trade Journal]

Publication: Electrical World

New York, NY, United States

p. 1036, col. 1

NEW INSULATOR TIE IS

DEVELOPED BY UTILITY

St. Louis Company Overcomes Difficulty Experienced

with Standard N. E. L. A. Ties on Two

Makes of 13,000-Volt Insulators

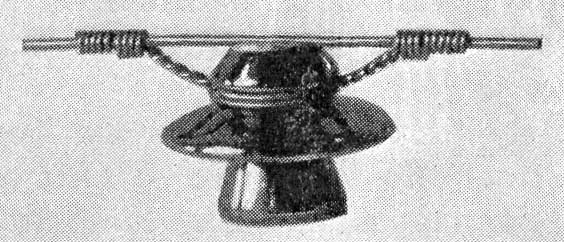

The Union Electric Light & Power Company, St. Louis, has developed an insulator tie which it finds more satisfactory for use on Thomas No. 2020 and Ohio Brass No. 9408 insulators than any of the commonly used 13,000-volt insulator ties. It found by experience that the groove on these insulators would not keep the ordinary ties from slipping off or from permitting the line to pull the ties off the insulators. This led to the development of the tie shown in the illustration, and in no case has the line wire become detached from the insulator when the line has been fastened by a tie of this character.

| |||

| New Tie Keeps Line Wire From Being Pulled Off Insulator and Can Be Served Without Cutting Wire. |

With the commonly used ties the linemen could not hold the wire in place on small angles, where the tendency is to pull away from the insulator sideways, and the same trouble was experienced where there was a slight dip in the line and the tendency was for the line wire to lift off the insulator. It will be noted in the photograph that these difficulties have been entirely eliminated, as the two loops around the tie groove of the insulator are in reality bands which are tightly fitted to the insulator and cannot slip up over the knob or top. When the standard ties, such as those referred to in Section 10, pages 7-14 to 17 inclusive, of the "Overhead Line Construction Handbook" of the National Electric Light Association, were used, the line wire was often injured by nicks or cuts in serving the tie. These mechanical defects in the wire sometimes caused the line wire to break at a later date. This difficulty has also been overcome by the St. Louis engineers in their new tie, as it is not necessary to touch the line wire with the connectors when serving up the tie shown.

The line wire in the illustration is No. 0 and the tie is No. 4 copper wire, which must be "dead" soft. The length of tie wire required under these conditions for the Thomas No. 2020 or the Ohio Brass No. 9408 insulators is 6 ft. 4 in. (1.93 m.), and the weight is 0.8 lb. (0.363 kg).