[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 42, no. 1, p. 5-8, col. 1-3

ELECTRICAL PROGRES IN UNITED STATES IN 1907

BY HENRY H. NORRIS.

INspite of the financial stringency which marked the close of the year 1907, the electrical industries show substantial progress. As was generally expected, the great rush of business of the last few years could not last, and now a temporary reaction is being experienced. That this can be of long duration few believe, as the country is prosperous and the necessity for extensions and new projects in all electrical fields is as great as ever. The announcement that some of the Westinghouse companies had applied for a receiver was the cause of general regret. It is expected that the companies will be reorganized and the receiverships terminated in the near future. Except for the reduction in the number of employes of this and other companies and the consequent diminution of output, the natural development of the industry has not been interrupted. New inventions continue to be made and new applications are found for standard apparatus.

THE INSTITUTE.

Early in the year the American Institute of Electrical Engineers was installed in the new headquarters in the Engineering Societies Building at 33 West Thirty-ninth Street, New York city. The first meeting in the auditorium was on January 25th, when Messrs. Stillwell and Putnam delivered a paper on the substitution of the electric motor for the steam locomotive. The audience completely filled the large hall and thus indicated appreciation not only of the paper but of the splendid facilities afforded by the new assembly room. The building was dedicated on April 16th and 17th with appropriate ceremonies, consisting of addresses and other exercises. In addition to the facilities provided for meetings, the new building houses the union library of the three founder societies. Since November 6th this has been open evenings, and it is bound to become a factor in the broadening of engineering intelligence.

The growth of the Institute during the last year has been phenomenal. On May 1st there were 4,521 associates and members, as compared with 3,460 the year before, an increase of 29.8 per cent. By October 1st there were 5,089 members, indicating a yearly rate of increase of 30.3 per cent., if the interest continues unabated. At the average present rate of increase there should be 5,877 members on May 1, 1908, an increase for the year of 1,356. This does not include the enrolled students, of whom there are more than 1,000.

The growth is due largely to the activity of the Institute branches and sections. Of the former there are 19, located at the principal educational institutions. There are 18 sections, with headquarters in a number of large cities scattered from Boston to Seattle. Two of the sections, Toledo and Cleveland, have been organized in the last year, as have also the branches at Montana University and the Montana Agricultural College.

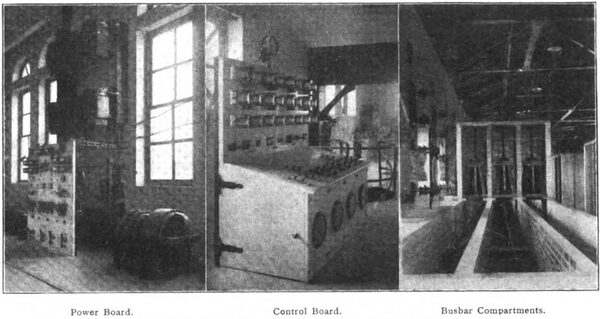

| |||

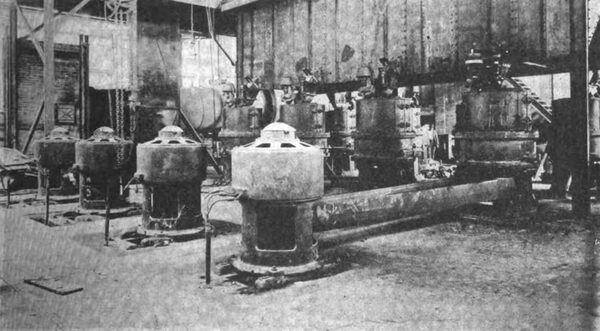

| Views in Western Avenue Sub-Station of Chicago Drainage Canal Power Transmission. |

The Niagara Falls convention of the Institute was the occasion for the presentation of a bewildering array of papers and reports. On account of the location of the meeting in the center of an important power-transmission district, special attention was given to this subject. The problems of transmission at very high pressures were carefully treated and the discussion clearly indicated considerable increases in line pressures in the near future. Aside from the technical papers, the convention manifested interest in such matters as the new standardization report, which was approved; the Code of Engineering Ethics, a most timely compilation of the niceties of business courtesy; and engineering education.

During the year the United States national committee of the International Electrotechnical Commission was appointed. It is organized with Prof. Elihu Thomson as chairman, and with twenty other members. These are all men of achievement, and they have been selected to represent all branches of electrical science and industry. They will supplement the rather accidental international congresses and give stability to the growth of standardization.

TECHNICAL EDUCATION.

It is gratifying to electrical educators to note the increasing appreciation of their work by the profession at large. The teachers also show their desire to improve the methods of instruction to meet the real demands of the time. An important factor in this growing spirit of co-operation is the recognition, by all concerned, of the true functions of a technical training. The Society for the Promotion of Engineering Education, which has for its purpose the improvement of methods and ideals in all lines of technological teaching, has stimulated interest among the teachers and is now endeavoring to come more closely into contact with practical engineers. At the convention held at Cleveland in July, a plan for promoting a careful study of the status and possible improvement of technical and industrial education was formulated. The leading engineering societies were invited to appoint representatives to serve upon a joint committee for the above purpose, and they have since done so. As this committee is to report progress in one year and make a final report in two years, it will undoubtedly begin work immediately.

As a result of a recent canvass made by Mr. W. D. Weaver, there appear to be about 9,000 students of electrical engineering in all grades of schools. More than 1,350 were graduated in 1907. About 42 per cent. of these are from first-class schools, 47 per cent. are from schools of average rank, and the remainder are from schools in which the instruction is elementary in character.

| |||

| Transmission Lines Entering Western Avenue Sub-Station. |

In connection with the discussion of higher education, industrial training for young men who cannot afford the time and money for a college course is receiving consideration. The largest effort in this direction is represented by the Carnegie Technical Schools and Institute in Pittsburg, dedicated with great ceremony on April 11th. In this enterprise $23,000,000 has been invested. The great library and museums are the center for the literature, science and art of the vicinity. As might be expected, these schools are already immensely popular, and their capacity alone limits the number of students registered. This verifies the assertion made during the last year by prominent educators regarding the urgent need for more and better industrial education. At least one state has during the past year seriously taken this matter up and secured expert advice regarding the desirability of expending public money for the purpose.

Many schools were favored in 1907 by gifts and improvements. Mrs. Russell Sage's gift of $1,000, 000 to Rensselaer Polytechnic Institute of Troy, N. Y., has resulted in the formation of the Russell Sage School of Mechanical and Electrical Engineering. During the summer the new electrical engineering building of Worcester Polytechnic Institute was completed and the faculty was enlarged at the same time. This school has always been noted for the practical nature of its instruction. The new laboratory and classrooms are admirably fitted for teaching of the best type, and the building is probably the finest in. this country devoted exclusively to electrical engineering instruction.

|

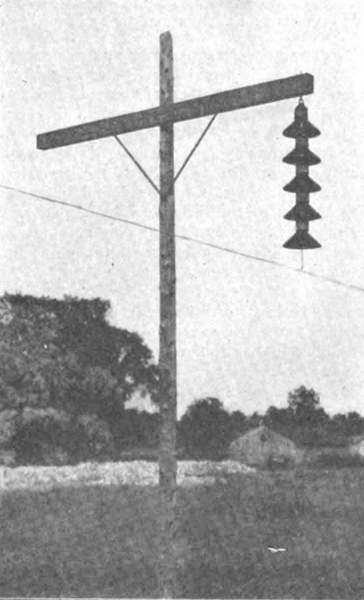

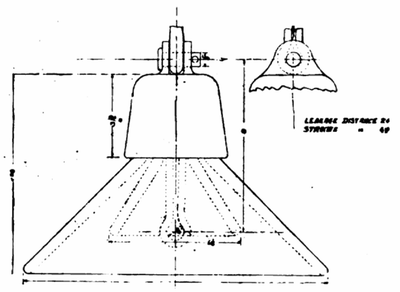

| One Section of the New Type of Suspension Insulator for High Voltages. |

From all parts of the country come tidings of improvement. At Annapolis the electrical course is being reorganized with a view to preparing the cadets for the proper use and application of electrical apparatus. The government engineer school at Washington has demonstrated its usefulness. The new engineering course at George Washington University has passed a successful third year. The graduate engineering school at Harvard has proved popular and timely. All these and many other facts are encouraging for the future of the electrical profession. Research also is not being neglected. On account of the growing pressure upon the funds of the Carnegie Institution, the founder last month added $2,000,000 to its endowment.

ILLUMINATION.

One year ago there was a bewildering series of inventions of new light sources, each outdoing its predecessor in efficiency. These inventions led to great activity in the commercialization of the lamps which has proved to be the important illumination problem of the year. It was soon evident that efficiency is but one of a number of important points of merit in light sources. Color, illuminating quality, expense of trimming, cost of lamps and electrodes, adaptability to standard circuits, production of fumes, and other matters required minute attention. During the year the various forms of lamp have automatically taken possession of their own fields.

| |||

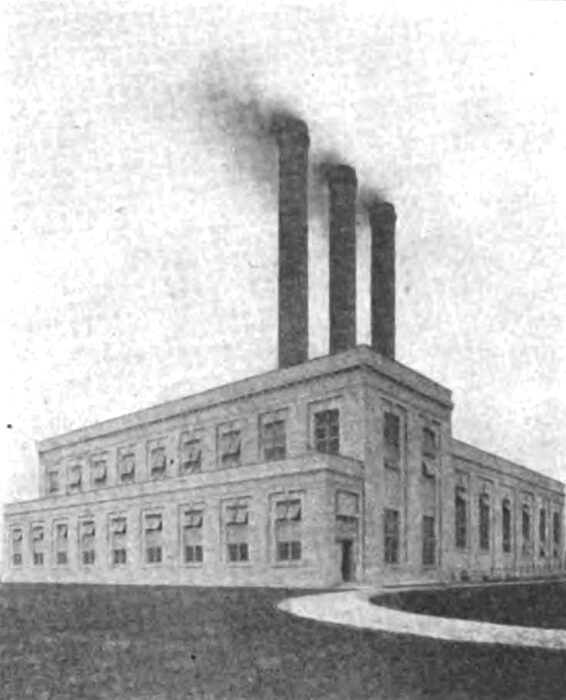

| The New Concrete-Block Power House of the Washington Railway and Electric Company at Bennings, Md. |

The General Electric magnetite arc lamp with iron oxide and copper electrodes has demonstrated its practicability for commercial service, especially for street lighting. It is now being adapted for locomotive and interurban car headlights and will undoubtedly compete with the carbon arc in other fields. Fifteen thousand magnetite lamps are now said to be in operation, and the number is rapidly increasing.

The Westinghouse company has also recently perfected a metallic flame arc lamp on the same general principle. In these lamps the most difficult problem is the disposition of the products of combustion of the electrodes, slag and fumes. By the use of skillfully directed air currents the fumes are carried out of the globe, which is not clouded by them. A chimney located above the arc produces the necessary air circulation. The slag which accumulates on the lower electrode is jarred off as it accumulates and is caught in a small pan.

| |||

| A Suspension Insulator for 100,000 Volts. |

The magnetite arc has created a new and unexpected field for the mercury arc rectifier, which has been developed to a satisfactory commercial stage. Obviously, the magnetite arc, having two differing electrodes, requires direct current for its operation. This unfortunate feature renders necessary the use of transforming apparatus, as, in most cases, a direct, constant-current generator would be very objectionable. The mercury rectifier eliminates the commutator and other evils of the direct current arc machine, and, unless a new form of arc lamp appears in the near future, it will be a part of the standard arc-lamp equipment.

The magnetite arc should not be confused with the flaming carbon arc lamp. The former produces a white light, somewhat less blue, but otherwise not radically different from that of the older car bon arc lamps. While not as efficient as the carbon flame arcs, the metallic flame arc has a better color and is of less intensity. As compared with the ordinary carbon arcs, the efficiency is at least 50 per cent. better. There are no inner globes, and the total expense of trimming is probably not far different in the two cases.

The carbon flame arcs are being introduced in large numbers for spectacular effects. They are placed principally in front of stores to attract attention, and brilliantly illuminate the window displays. The efficiency of these lamps is of the highest, and for the purpose mentioned they are very satisfactory. The yellow color, the necessary frequency of trimming, the fumes produced and the great intensity of the light limit the field of application of the carbon flame arcs.

Excellent progress has also been made by the incandescent lamp in its several forms. Tantalum lamps are now in general use on direct-current circuits, and they are apparently giving entire satisfaction. At the present price of from 50 to 75 cents they are economical as compared with the ordinary carbon-filament lamp. The manufacturers advertise them as considerably more efficient than the metallized carbon-filament lamps. The life on alternating-current circuits is about one-half that on direct-current circuits, hence the lamps are used principally in isolated plants and on the Edison systems in the very large cities.

Tungsten lamps are slowly coming into the market. Naturally the first lamps manufactured were for series lighting, a larger current and lower electromotive force permitting the use of a comparatively large filament. These lamps are well adapted to street lighting, as the units are of convenient size for uniform distribution and the efficiency is arc. practically the same as that of the enclosed carbon arc. As there is no trimming, the expense of maintenance is simply the cost of replacing the lamps, which are said to have a good life. In one such installation the lamps are placed in groups of two, 280 feet apart. Each lamp requires 14.7 volts at 5.5 amperes, to produce 60 candlepower, or 1.35 watts per candlepower. Lamps of 110 volts and of 40 and 20 candlepower are now being imported in considerable numbers, but sufficient experience has not yet been accumulated to permit of a conclusive statement of the results. The long slender wire is delicate and requires careful handling when heated. Properly used, the lamp will undoubtedly have a satisfactory life, and the efficiency is far higher than that of any other small-unit lamp commercially available. At the present high price of the imported lamp, not far from $2 retail, the demand will not be greatly in excess of the supply.

A matter of general interest was the recent great increase in the demand for standard incandescent lamps, resulting in an approach to a lamp famine. Successful plans for increasing the use of electric light have been exploited, and manufacturers have been overworked to furnish lamps.

Among the novelties in illumination, the lighting of the Jamestown Exposition and of Niagara Falls deserve mention. Both of these are notable in the use which has been made of searchlights. Behind the administration building at the exposition a battery of searchlights was located. This threw up ward a radial group of light beams which produced a magnificent corona about the dome of the building.

|

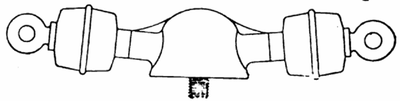

| Special Hanger for 1,200-Volt Direct-Current Railway Construction. |

When the mayor of Niagara Fails, in his ad dress of welcome to the Institute, mentioned his plans for illuminating the falls, his audience was somewhat incredulous. However, on September 4th the first exhibition was made. Batteries of 18, 30 and 60-inch projectors were located at various points on the Canadian side, and beautiful effects were produced by throwing white and colored light upon the falls and the spray. This was probably the most extensive use of searchlights yet made for scenic purposes.

The convention of the National Electric Light Association in Washington in June was the most notable and the largest in the history of the organization. The association placed itself on record as being willing to accept the principle of public control of public-utility corporations if applied fairly. It adopted a new standard for street illumination and devoted one whole day to topics connected with the getting and retaining of business for central stations.

ELECTRIC TRACTION.

Steam-railroad electrification has been one of the absorbing topics of the past year. Whenever and wherever discussed, large and interested audiences were present. As mentioned earlier, the opening meeting of the Institute in the new building was devoted to this topic, and an exceptionally large number of other papers have treated of it.

The subject divides itself naturally into two parts-first, under what circumstances should steam roads be electrified second, under what particular conditions is the direct-current or the alternating current motor to be preferred? There has been some criticism on the part of steam-railroad men that electrical engineers are forcing this matter too rapidly. At the same time substantial progress has been made both in direct-current and alternating current railroad electrification.

After years of experimentation, late in the spring the New York Central Railroad began full electrical operation on the New York terminal with direct-current locomotives. One of the early passenger runs, on February 16th, was the occasion of a serious accident, in which a score of persons were killed and more than one hundred were injured. The cause of this accident has been variously explained, some experts maintaining that the low center of gravity of the locomotive would account for the shearing of the rail spikes, others holding that it was due to excessive speed. The fact is that the train was derailed through spreading of the track. The exact speed may never be ascertained, as witnesses on the train estimate it at from 45 to 80 miles an hour. The superintendent of the road was indicted for manslaughter, and after thorough trial was acquitted early in December. It was shown that all reasonable precaution had been taken by those responsible for the condition of the track and the operation of the road. After more than six months of electrical operation the management is convinced that electrification has resulted in marked increase of efficiency and in financial saving.

| |||

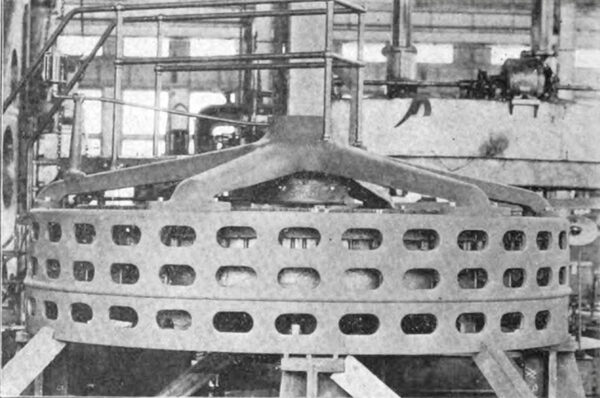

| Electric Motors Driving Cement Mills. |

The New York, New Haven and Hartford Rail road, which uses the New York Central electrical terminal, has recently established regular service with its alternating-current locomotives. Twelve miles of track, beginning at the terminal, are sup plied with direct current at 600 volts from a third rail. More than 22 miles of four-track road is equipped with double catenary trolley carrying 25 cycle current at 11,000 volts. At present 35 93-ton locomotives are used, each being capable of drawing a 200-ton train at 45 miles an hour maximum speed in local service and at 60 miles an hour in express service. While this road has not been in operation a sufficient length of time to permit an estimate of the results, its electrical engineer is convinced that great economy is sure to follow.

As the chief function of electrification appears to be the increase of capacity, particularly in congested terminals, the results of this stupendous experiment at New York will be awaited with interest. Other roads are already planning to utilize this remedy for congested traffic. The Southern Pacific Rail road is now contemplating the electrification of the Sierra Nevada division, aptly termed by Mr. Sprague the "neck of the bottle" This proposition differs from others, in that it is proposed to handle freight trains weighing 1,000 tons or more over a grade of 12 per cent. and 83 miles long. The matter has been referred to an advisory board, which will reach a decision in a few months.

The Erie Railroad put into commission early in the year an electrical section, the Rochester division. Apparently this was done to ascertain the facts regarding electrical operation, and thus secure data for future electrification. Trolley construction for 11,000 volts is employed, and, as far as can be learned, the new motive power has given satisfactory results.

Since the pioneer tunnel locomotives of the Baltimore and Ohio Railroad were placed in commission more than ten years ago, this field has been an at tractive one for the electric locomotive. The Sarnia tunnel, between Port Huron, Mich., and Sarnia, Ont., will shortly be fully equipped. Trains will be hauled between these cities by 3,300-volt, 25 cycle locomotives weighing 62 tons each.

The Pennsylvania Railroad, which is rapidly completing its tunnels between New Jersey, New York and Long Island, is experimenting with both direct current and alternating-current locomotives. Sample equipments have been constructed and are now under test. The requirements are severe, necessitating high speed on grades of two per cent. A decision will be reached in a few weeks regarding the type to be employed. This company will use all-steel construction both for day coaches and Pullman cars.

All of the progress mentioned has been with the series motor. Although abroad the three-phase motor has been developed for traction work to a remarkable degree, it has found little favor here. It is especially noteworthy, therefore, that the Great Northern Railway has selected the induction motor for a mountain division. Its consulting engineer states that the constant-speed characteristics and the possibilities of power regeneration have been important factors in this selection.

Aside from locomotive service, the alternating electric-railway motor has made a satisfactory advance during the year. There has been no whole sale changing over to the new form of motor, but such roads as the Pittsburg and Butler Street Railway, the Visalia Electric Company, the Chicago, Lake Shore and South Bend Railway and the Maryland Electric Railway have selected the series alternating-current motor. The Visalia line is the first to employ the low frequency of 15 cycles. In addition to new construction of 13 miles, there are 10 miles of electrified steam track. The line pressure is 3,300 volts.

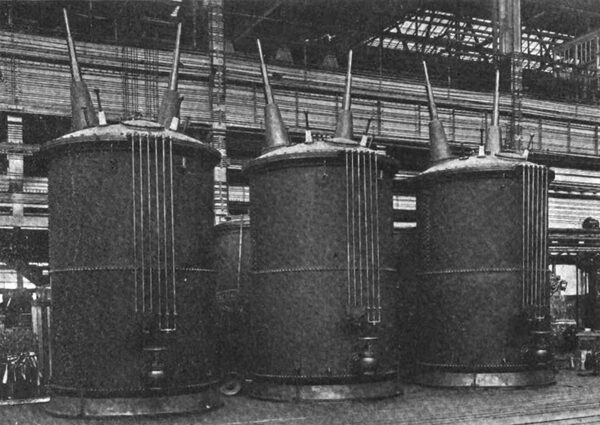

| |||

| Single-Phase Transformers of 3,750 Kilowatts Capacity Each. (Largest of Their Type.) |

A year ago the interpole railway motor was in process of commercial application. It is now an assured success, having been adopted by a number of roads. The principal ones at present are the Central California Traction Company, mentioned in last year's review, the Pittsburgh, Harmony, New Castle and Butler, the Indianapolis, Columbus and Southern and the San Josť and Santa Clara rail ways. These roads will operate at 1,200 volts, and in one case at least the secondary current for the commutating poles will be supplied from a separate exciter at 600 volts. The Indianapolis and Louisville line, although 41 miles long, will be operated from a direct-current station located near the center of the line and without sub-stations of any kind. This indicates the possibilities of direct-current transmission at the higher pressures, the possible range of operation increasing greatly with the 1,200-volt transmission.

The higher voltages, for alternating current especially, have required better insulators, and the manufacturers have met the demand with fair success. Undoubtedly the serious problem at present is the safe and secure support of the slender overhead wires, so that danger may be eliminated and increased reliability secured.

The American Street and Interurban Railway Association closed its second year with a great convention at Atlantic City. A mammoth exhibit covered the Steel Pier and the sessions were extremely profitable. The most noteworthy achievement was the adoption of a Code of Standards for electric-railway equipment, prepared by the Engineering Association. On January 1, 1908, an expert statistician was added to the secretary's force, and a special effort will now be made to secure and arrange a most complete collection of electric-railway data.

POWER GENERATION.

As a prime mover for steam-power stations the steam turbine has demonstrated its superiority and has proved entirely reliable. For the present the limit of size appears to have been reached, not because of the impracticability of building larger turbines, but because there is no advantage in doing so. The Rateau turbine, of the impulse type, has taken its place with the well-known Curtis, Parsons, Allis-Chalmers and de Laval engines. The direct-current generator has been successfully adapted to turbine speeds, and thus a new field is opened up for the turbine. In a recent Institute paper a description of an exhaust turbine installation, along the lines suggested by Mr. H. G. Stott, is described. The plant is that of the Wisconsin Steel Company at South Chicago. A 1,000 horsepower reciprocating engine delivers its exhaust steam into a regenerator or heat-storage reservoir in which the heat is absorbed by a large volume of water. The turbine draws its steam from this at slightly above atmospheric pressure and exhausts into condensers. As the load on the engine is variable, the regenerator is necessary in order to produce a uniform supply of steam to the turbine. The turbine drives a direct-current generator of special construction.

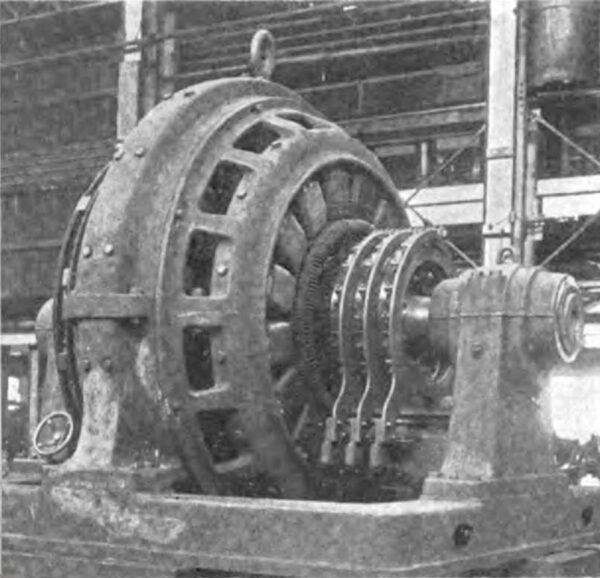

| |||

| The Booster is the Right-Hand Part of the Machine. Combined Rotary Converter and Booster. |

One of the most complete power stations of the past year is the Bennings (Md.) station of the Washington Railway and Electric Company of Washington, D. C., installed by J. G. White & Co., and described in the Western Electrician of June 1, 1907. Here the engine room presents a particularly neat appearance, on account of the absence of all auxiliaries, which are located on the floor below. The new station is of interest as typical of the present tendency toward compact, neat and simple construction. On account of its proximity to the city special attention has been given to the architecture, which is comparable with the buildings at Niagara Falls.

An annual review is incomplete without mention of the plants at the great waterpower center. All of the projects have reached a satisfactory stage and each is supplying its own territory with power. The beautiful building of the Electrical Development Company fulfills all expectations. This company has been during the year supplying Toronto with power. The Niagara Falls Power. Company's new plant corresponds in general style with the American power houses. The Ontario Power Company has several units in operation, and is supplying power at Syracuse and at many points en route. The new power house of the Niagara Falls Hydraulic Power and Manufacturing Company is the latest project. Sixty thousand horsepower of units was installed during the year. This will all be used focally.

| |||

| A 3,250-Kilowatt Turbo-Generator Under Test. |

The gas engine as a prime mover is increasing in popularity, and it imposes special conditions upon generator design. A typical installation containing the largest gas-engine-driven alternators in the world is the Martin Station of the California Gas and Electric Corporation. These Crocker-Wheeler machines have kept in step under the most violent fluctuations of load, and even under back explosions of the gas engines. The Allis-Chalmers Company has delivered two 2,000-kilowatt gas-engine alternators to the Illinois Steel Company, and others to the American Steel and Wire Company and to the Milwaukee Northern Railway. The latter has the largest gas-engine electric-railway power plant in the country. It has at present two 2,000-horsepower units, each consisting of a four-cylinder gas engine directly driving, at 107 revolutions per minute, a 405-volt, 25-cycle alternator.

One of the novel developments in electrical machinery is the combined rotary converter and booster installed by the Westinghouse Electric and Manufacturing Company for the New York Edison Company. The booster is an alternator mounted on the same shaft as the converter and forming mechanically an integral part of it. The booster armature is connected in series with the alternating-current side of the converter between the rotary collector and the rotary armature winding. It does not, therefore, require a separate collector and brush-holder mechanism. The direct-current volt age of the rotary may be raised or lowered by reversing the current in the booster field circuits, thus giving a regulation twice as great as that represented by the booster capacity. The regulation may be either manual or automatic. The de vice seems to represent a marked improvement over previous methods of converter regulation.

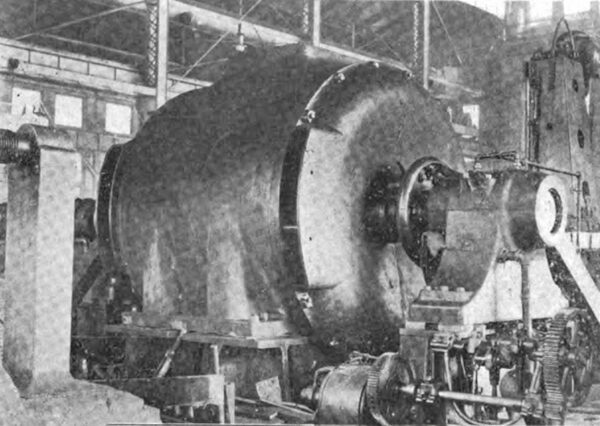

| |||

| A Vertical 450-Horsepower Induction Motor to Drive Centrifugal Pump. |

As the generating units in power stations improve, so also do the detail parts, such as instruments, circuit-breakers, lightning arresters, etc. This line of work has improved in a marked degree of late, particularly in adapting the apparatus to increasing pressures. Two Westinghouse devices that deserve special notice are the electrolytic lightning arrester and the automatic synchronizer. The former is familiar in principle, as it was described last year in an Institute paper. It has now been put into service and has been applied up to 60,000 volts. If it proves commercially successful it will mark a real step in a direction in which progress is needed. The synchronizer consists of a contact arm which is oscillated by two magnet coils, the oscillations corresponding to the difference in frequency of the two circuits to be connected together. When the rate is sufficiently slow a contact spring bridges a gap between two contact plates carried by the arm. Current flows across the gap from an auxiliary circuit and operates the mechanism controlling the main switch which is thrown in.

POWER TRANSMISSION.

Power transmission continues to develop new problems, particularly as the tendency to increase line pressures continues. While size is of secondary importance, it is interesting to note that the record has been broken again in transformer construction. The Grand Rapids and Muskegon Power Company has purchased a number of 100,000-volt, 3,750-kilowatt capacity, single-phase transformers, the largest yet constructed. It will be but a short time before 100,000 volts will be the standard high line pressure. The pin-supported insulator is not adapted to pressure much above 60,000 volts, as it is too tall to have the necessary mechanical strength. A radically new type has therefore been developed. This insulator hangs from the cross-arm with the transmission wire at the bottom. It is in sections, each of which may be large enough to withstand 20,000 volts. In one form, described by Mr. E. M. Hewlett at Niagara Falls, the sections consist of separate porcelain dish-shaped disks held together with steel wire loops. These loops, in passing through eyes in the porcelain, link together, giving the name "link" insulator. The Locke Insulator Manufacturing Company has under construction a large number of insulators on this general principle, although differing radically in appearance from those described by Mr. Hewlett.

Several power-transmission schemes have been completed during the past year. One that has attracted attention is the system of the Ontario Power Company. This was fully described by the engineer, Mr. R, D. Mershon, at Niagara Falls. This line will be an important factor in the industrial development of Central New York. Another important new hydro-electric plant is that of the Chicago Drainage Canal, described and illustrated else where in this issue.

POWER REPRODUCTION.

While less spectacular than some other lines of progress the application of the electric motor to new uses and in growing quantities is having an important bearing on industrial development. Not only are standard motors being largely bought and applied to various loads, but special motors, horizontal and vertical, are being designed. The largest as well as the smallest manufacturing companies are devoting attention to the small motor, even down to one-twentieth horsepower.

The steel mills present at present an attractive field for electric drive. At the plant of the Illinois Steel Company in South Chicago a 30-inch plate mill has two 2,000-horsepower, 575-volt, direct-current Westinghouse motors direct connected to the rolls and with a speed variation from zero to 150 revolutions per minute. These motors are supplied with current from a motor-generator equalizer set. A 1,300-horsepower induction motor drives a direct current generator. Heavy flywheels, each weighing 50 tons, serve to absorb energy during light load and restore it when the rolls require extra power. The speed of the equalizer motor is reduced automatically by resistance inserted in the secondary when the load is heavy.

At the same plant is a re-rolling mill direct driven by two induction motors, one with 12, the other with 24 poles. When connected in tandem the capacity is 1,800 horsepower. Separately the 24 pole motor produces 1,200 horsepower. Heavy fly wheels are mounted on the motor shafts.

So important has the steel-mill business become that special lines of motors are being designed for it. During the past year the Crocker-Wheeler Company has installed a number of motors of a rugged type, with great commutating ability. In addition to the motors described the Westinghouse Company has equipped several mills. In the last year's review the 6,000-horsepower motor designed by the General Electric Company for the Indiana Steel Company was mentioned. Wherever furnace gas is available there is a field for the electric motor, driven from gas engines as prime movers. The direct-current motor is most readily adaptable to mill conditions, but there is a field for the induction motor, and the two in combination appear to be ideal.

TRANSMISSION OF INTELLIGENCE.

From the commercial standpoint the most prominent fact of the year in telegraphic circles was the great operators' strike. After numerous local difficulties in several sections had led to strikes and concessions, and after strenuous efforts on the part of Labor Commissioner Neill to effect a compromise, a general strike of the Telegraphers' Union was declared early in the summer. All commercial operators of both companies were affected and for a short time business was seriously interfered with. The companies soon restored their service to a remarkable degree of efficiency under the circumstances. The companies apparently have been victorious in the struggle, and business is now transacted as usual. Public sympathy does not seem to have been very strong in favor of the strikers.

The strike is said to have had a stimulating influence upon the automatic high-speed telegraph development. In August the Postal company added to its Rowland equipment the Chicago-St. Louis and New York-Philadelphia lines, having had the Boston-New York line in successful operation for a year or more. This is a very significant situation. Apparently the Delaney system is to be tried upon a large scale as it is now being exploited commercially. The general plan is to connect the large cities by trunk lines, over which the messages will be sent at high speed and received on chemical tape. From the main centers they will be distributed by the most convenient and economical means.

After years of experimentation, commercial transatlantic service by radio-telegraphy has been established. On Friday, October 18th, 14,000 words were transmitted by the Marconi company between the two coast stations-Glace Bay, Nova Scotia, and Clifden, Ireland. The messages are carried at much lower rates than over the cables, and there is no reason to believe that sufficient business will not develop to keep the plants busy continually.

Radio-telegraphy on land is also making substantial progress. For example, in Alaska, when conditions are especially adapted to this means of communication, regular business has been con ducted for some time. At present the United States Signal Corps is extending the equipment to cover Safety Harbor, St. Michael, Fairbanks, Circle and Valdez.

In automatic telephony some interesting improvements are reported. The perfection of the new line switch is one. By its use the number of first selector switches in an exchange is reduced 90 per cent. The space occupied by a complete exchange is less than one-quarter of that formerly required and the total number of working parts and consequent cost of maintenance correspondingly reduced. Common battery for transmission has been made a permanent feature of the automatic system, and all switchboards installed during the year have been of the common-battery type. Νο extra battery is required, the regular operating battery being used for supplying current to the transmitters as well as for operating the switches. The demand for party lines in connection with the automatic system has resulted in the perfection of the four-party selective ringing system, which employs the well-known "harmonic" principle of selection. The four subscribers on a line have different numbers and only the bell of the subscriber called is rung. Another new feature is the "district station," the object of which is to reduce the cost of construction of a cable plant 50 to 75 per cent. by employing trunk lines only to serve the different districts comprising an exchange. Switchboard units, small and compact, and which require practically no attention, being supervised from the central exchange, are installed in the center of the different districts or suburbs, these units being connected to the main exchange by the requisite number of trunk lines.

Radio-telephony is now an accomplished fact and is in regular use. The 16 battleships of the Pacific fleet, which recently sailed on its long voyage, are equipped with the De Forest system. In general this differs only in detail from the radio telegraph system. The underlying principle consists in the production and transmission of high-frequency oscillations which form the foundation of the sound waves. They are of much higher frequency than the sound waves and are produced by an alcohol flame shunted across the terminals of a direct-current generator, in series with which are capacity and inductance. Variations in the strength of the oscillations corresponding to the soundwaves, are superimposed upon the oscillations by a micro phone in the circuit. They are received on the "audion" receiver described by Mr. De Forest in an Institute paper last year. The utility of this invention is obvious, especially as installed on the fleet.

SUMMARY AND CONCLUSIONS.

As a whole the year 1907 has been as fruitful in substantial results as any of its predecessors. Especially in the commercial application of scientific discoveries and inventions has the development been most marked. In spite of financial and industrial disturbance, real and substantial results have been secured. The commercial interests have lost a commanding figure in the death of Colonel Eugene Griffin. So also has the scientific and teaching fraternity in the death of Prof. C. P. Matthews. America loses also a firm friend in Lord Kelvin, who passed away on December 17th at the age of 83 years. It is a coincidence that at this time the ocean cable system, to which he devoted some of his best energies, has a rival in the wireless system, to which, however, he gave a cordial welcome.