[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 38, no. 23, p. 464-467, col. 1-3

Power-transmission Line and Third-rail

System of the Long Island Railroad.

Transmission lines of the Long Island Railroad to be first equipped comprise the Atlantic Avenue division, between Flatbush terminal and Belmont Park, and the Rockaway Beach division between Woodhaven Junction and Rockaway Park. The equipment of this latter division has also been extended to enable electric operation via Far Rock-away to Valley Stream.

A study of the traffic conditions to be met by the electric equipment upon these divisions resulted in a preference for sub-station sites at Woodhaven Junction, East New York, Flatbush Avenue, Rock-away Junction and Hammel. These were ultimately selected as permanent sub-station locations, except that Grand Avenue, about one mile out from the terminal, was later on substituted for Flatbush Avenue.

Since the original installation described in this article was completed, a sixth sub-station has been located at Valley Stream, receiving its power from an extension of the overhead line by way of Springfield Junction.

Two portable sub-stations were also provided as the most economical method of supplying current for the very heavy periodic traffic to and from the Metropolitan race track south of Jamaica, and the new Belmont Park race track about five miles east of Jamaica. These loads occur for two hours each day, for periods of two weeks, twice a year. The portable sub-stations consist of 1,000-kilowatt rotary-converter outfits, complete with transformers and switchboard, each mounted in a heavy steel boxcar.

The topography of the system is such that Woodhaven Junction sub-station becomes a natural distributing center between the power house and the other sub-stations, and it was therefore decided to make it the objective point of a main power transmission trunk line which should bring directly to it the entire output of the power station for distribution among the sub-stations. The problem of line construction was therefore to build a trunk line from the main power station to Woodhaven Junction, with two branch transmission lines running along Atlantic Avenue between Grand Avenue and Rockaway Junction, with two subordinate branches from Rockaway Junction to the two race tracks, and a third subordinate branch running directly south from Woodhaven to Hammel sub-station across the Jamaica Bay trestle.

The trunk line as originally built carries five circuits from the power station to Woodhaven Junction sub-station, running in an 18-duct conduit line to Dutchkills Street, thence on a line of steel poles which follows the right-of-way of the main-line division to a point about due north of Glendale Junction, where it bends to the south across the fields for about a mile, until it strikes the Rock-away Beach division, which it follows to Woodhaven Junction. A branch line of three circuits runs westward from Woodhaven Junction to the East New York sub-station, two circuits running thence to Grand Avenue sub-station, all these being run in underground conduits. To the east of Woodhaven Junction there are two circuits run under-ground to Dunton, where the transmission is changed from underground to overhead, continuing easterly on steel poles to Rockaway Junction sub-station. The branch circuits from Rockaway Junction to the portable sub-station terminal buildings at Belmont Park and Springfield Junction are carried on wooden poles running along the main line and the Montauk division, respectively, to their destination. Southward from Woodhaven, two circuits follow the Rockaway Beach division across Jamaica Bay trestle to Hammel sub-station. These circuits are carried on a line of steel poles to the southern outskirts of Ozone Park, half a mile or more from the sub-station, and the remainder of the distance on wooden poles.

|

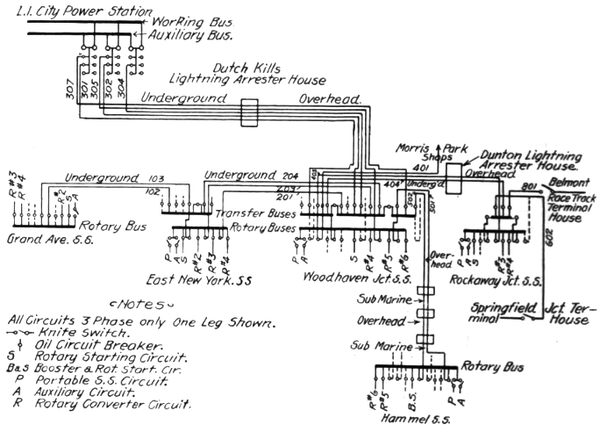

| Fig. I. Diagram of Transmission Circuits on Long Island Railroad. |

The general arrangement of the transmission circuits is shown in Fig. 1. It will be noted in this diagram that the incoming trunk-line circuits at Woodhaven Junction are distributed along a set of busbars called the "transfer bus" and divided into sections from which the outgoing transmission circuits lead in various directions. It is possible by manipulation of the bus junction switches to operate these circuits separately or together from outlying sub-stations all the way back to the power station. The same general arrangement is carried out in a smaller degree by similar transfer buses at East New York and Rockaway Junction.

The total mileage of conduit lines now in use is9.09 and that of pole lines 26.19 miles.

CONDUIT CONSTRUCTION.

Between the power station and the railroad tracks the construction of the duct line involved no serious complications, except such obstructions as are frequently met with in city streets. The remainder of the line involved not only some blasting through a ledge of rock, but was also rendered especially difficult because much of it was situated below the level of the ground water, which, for a large part of the distance, was nearly at the surface, so that special provision for the drainage of the ducts and manholes was necessary.

This conduit line is constructed of single vitrified lay ducts 18 inches long, with square holes 3 13-16 inches inside measurement and walls three-quarters inch thick. They were designed especially for this construction, and the ducts are seven-sixteenths inch greater diameter than usual in order to facilitate the installation of the three-conductor high-tension cables, which are nearly three inches in diameter. A single duct was preferred to multiple ducts because of the thicker wall between ducts, which is better able to resist heat in case of a possible short-circuit. A square hole with rounded corners was preferred as affording space for dirt and pebbles to slide to one side instead of being dragged along underneath the cable and injuring the sheath, as would be the case if round ducts had been used. The ducts are laid in cement mortar in such a way as to break joints in all cases, and are surrounded on the top, bottom and sides by a covering of concrete four inches thick, composed of one part Portland cement, 2½ parts sand and five parts broken stone. The ducts are arranged three wide and six high.

| |||

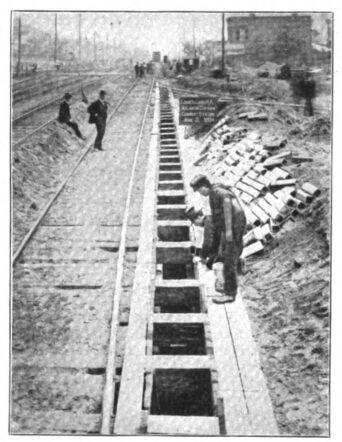

| Fig. 2. Conduit Manholes Close to Tracks on at-Lantic Division of Long Island Railroad. |

Manholes for drawing in and splicing the cables are located 400 feet apart on straight work and a shorter distance on curves. The standard manhole for straight-line work is eight feet long, four feet wide and 6½ feet high, inside dimensions. The corners are cut off so that a horizontal section of the manhole resembles an elongated octagon. The side walls at the bottom are 12 inches thick and at the top six inches thick, reinforced with expanded metal. The manholes are built of concrete, having a composition the same as that surrounding the ducts. An opening at the top is 25 inches square and is closed by two covers, the inner one of which can be locked, clamped and packed gas tight.

The conduit system on Atlantic Avenue comprises two kinds of construction. The portion lying between Atkins Avenue and Dunton, a distance of 4.4 miles, is in general identical with the above de-scribed construction for the main transmission line. It is installed on the south side of the tracks near the edge of the right-of-way. On this part of the construction the soil is of a very light sandy rature.so that the system is sufficiently drained by providing openings at the bottom of the manholes. As shown in Fig. 2, this section of the conduit construction was very close to the railroad track; in fact, the track overhung it for a good part of the distance, so that it became necessary to support the railroad track (which was in continual use), onone edge of the excavation.

Atlantic Avenue improvement conduits are built of four-way vitrified clay duct 36 inches long with square holes 338 inches on a side. These ducts are laid in cement mortar, the joints being first covered with cotton cloth saturated in Portland cement grout.

On the Subway portion of the improvement the man holes for the conduit lines consist of niches in the side walls five feet wide, 8½ feet in length and 15 feet high. On the other portions of the Atlantic Avenue improvement the manholes are built of concrete and are generally oval in form, seven feet long, five feet wide and 62 feet high inside.

UNDERGROUND CABLES.

Underground high-tension cables are of the three-conductor type, each conductor having a cross section of 250,000 circular mils and being composed of 37 copper wires. Each conductor is covered with a wrapping of impregnated paper seven-thirty-seconds inch thick. The interstices between the insulated strands are then filled in with jute insulation and another layer of seven-thirty-second-inch paper insulation is wound over the entire group. The outside sheath is nine-sixty-fourths inch thick and is composed of lead with about 12 per cent. of tin added. The completed cable is 2 7/8 inches, outside diameter. Each length of the cable was tested at the factory by applying 30,000 volts between each pair of conductors and between each conductor and the sheath; and after the cable was installed in the ducts and jointed up ready for service it was again tested by applying between each pair of conductors30,000 volts, and between each conductor and the sheath 27,000 volts for a period of 30 minutes.

At each end of every high-tension cable there is sweated on a spun-brass end-bell, which is filled with G. E. compound to properly seal the ends of the cable and prevent injurious static discharges. The end bell is about 734 inches in diameter and about seven inches high. The three conductors are brought out separately through a wooden head in the end-bell, after being wrapped with varnished cambric tape, and are surrounded by micanite tubes.

At the drawbridge in the Jamaica Bay trestle the cables are of the armored submarine type, and the conductors are insulated with seven-thirty-second inch of rubber around each strand, with another seven-thirty-second inch of rubber around the group of three. This insulation is composed of 30 per cent. pure Para rubber and is covered with a sheathing nine-sixty-fourths inch thick and com-posed of lead with about 1½ per cent. of tin added,and over this is an armor of No. 4 B. & S. galvan-ized iron wires laid spirally on the outside of thelead covering, with a thin layer of jute betweenthe lead and the armor. There are two such cablesat each drawbridge.

The high-tension cables are located in the lower portion of the conduit system wherever possible, with the idea of separating them from any other cables for different purposes which may be in-stalled subsequently. They are carried around the sides of the manholes in racks. The minimum radius of the bend in this type of cable is 18 inches. Where exposed in the manholes and at the sub-station terminals the cables are wrapped with a layer of hard-rolled asbestos mill board one-eighth inch thick, and outside of the asbestos millboard there is a wrapping of asbestos listing two inches wide, laid on until it averages three-eighths inch thick. The whole is then wrapped with galvanized-iron tape one-sixty-fourth inch thick and one-half inch wide, laid on with edges overlapping. At each manhole there is a strip of sheet copper sweated on to the lead sheath and brought out through the wrappings to allow of grounding the cable should it be necessary to protect it from electrolysis.

There is in all about 25 miles of high-tension underground cable installed, besides 0.418 mile of armored submarine cable.

ARRESTER HOUSES.

Vulnerability of underground cables to lightning and to other static disturbances which may be setup in the transmission line require that the outlying ends of transmission cables exposed to lightning discharges be provided with protective apparatus. Wherever the underground cable section of the transmission line is joined up with the overhead system, lightning arresters and choke coils are installed, suitable houses being provided to shelter this apparatus, there being one on the main transmission line at Dutchkills Street, Long Island City, and another at Dunton, on the branch line running east of Woodhaven. Smaller houses were also provided for the same purpose at the two drawbridges, one of which is shown in Fig. 3 at Broad Channel drawbridge.

| |||

| Fig. 3. Arrester House at Broad Channel Drawbridge. |

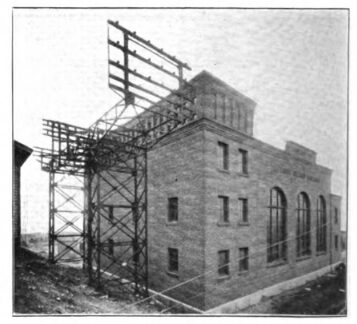

POWER-TRANSMISSION LINE AND THIRD-RAIL SYSTEM OF THE LONG ISLAND RAILROAD.

The house at Dutchkills Street is a brick structure and at present contains room sufficient for eight outgoing overhead circuits, which leave the house four on a side. The general design of the transmission line is such that the circuits on one side of the poles can be shut down for repairs without shutting down those on the other side, and this idea was carried out in the construction of the arrester house, so that there would be no confusion possible between live and dead conductors whenever it might become necessary to do any repair work on the line. Arresters are all provided with knife switches, so that they can be readily disconnected from the circuit. A choke coil is also provided in series with each main circuit and another knife switch between the choke coil and the cable bell, enabling the cable to be entirely disconnected from the overhead line. The disposition of the material is such as to economize space and at the same time makes each circuit capable of ready access without the necessity of incurring risk from other apparatus in case it needs repair.

A similar house to the foregoing is located at Dunton, where the branch transmission line running eastward from Woodhaven Junction is changed from conduit to overhead construction. At the drawbridge channels in Jamaica Bay three houses are provided to shelter similar apparatus.

OVERHEAD LINE CONSTRUCTION.

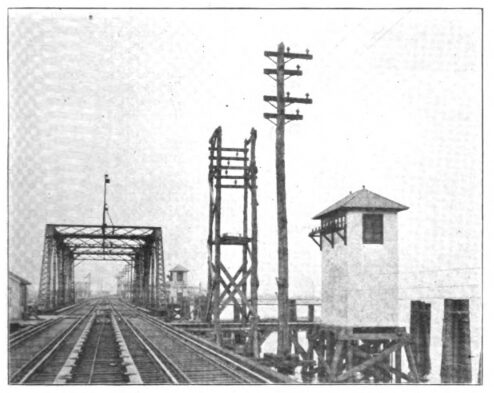

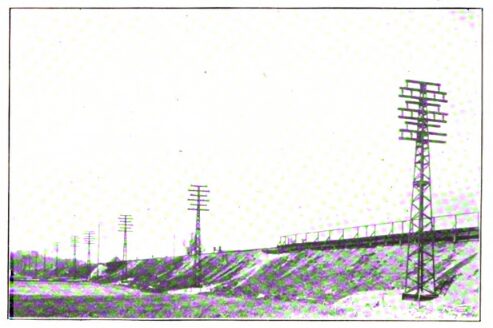

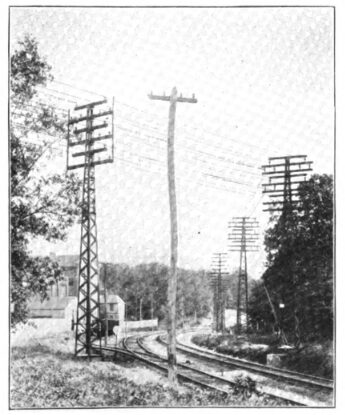

There are two general divisions of the overhead construction, the trunk line between Dutchkills Street and Woodhaven Junction and the branch lines between that point and the other outlying sub-stations. The trunk line shown in Fig. 4 is built of steel poles, and the branch line between Dunton and Rockaway Junction (Fig. 5), through which the latter sub-station and two portable sub-stations are fed, and upon which the circuits to stations not yet constructed may eventually run, is also equally important as the trunk line, and is therefore built of steel. From Rockaway Junction the branch pole lines to the separate outlying sub-stations are of wood. From Woodhaven Junction south the poles are of steel to the southern out-skirts of Ozone Park because of the rather exceptional height at which the cables have to be carried to clear other wires, but from Ozone Park to Hammel they are of wood.

The pole lines have not been duplicated for the sake of greater security, as is sometimes done where plenty of room is available for pole lines and where other conditions make it desirable. It was decided that a sufficient degree of insurance would be obtained by constructing a single-pole line in the most substantial manner. The suburban lines of the Long Island Railroad form several loops or meshes of a network which may afford an opportunity for the construction of additional transmission lines by other routes should future conditions require such a development.

The trunk line is designed to carry eight three-phase transmission circuits consisting of three 250,000-circular-mil cables each, together with eight low-tension cables of 500,000 circular mils each. As the latter, when installed, must be 25 feet above the ground, and as there must be a reasonably clear space between the low and the high-tension circuits, no argument is required to demonstrate the necessity for using steel-tower construction to carry such an unusual weight of overhead conductors.

The branch-line transmission circuits, however, are not intended to carry more than two three-phase transmission circuits and four low-tension cables on a single line of poles. This condition enabled the use of wooden poles, of which an extra-heavy type was selected, in order that the idea of stability might be consistently carried out.

POLE LINE AND EQUIPMENT.

The steel poles are of various sizes to meet differing conditions. They are all designed to carry 24 250,000-circular-mil cables on their upper portions, and underneath them an additional load of eight 500,000-circular-mil low-tension cables, which local regulations require to be at least 25 feet above the ground. The spans between steel poles average 150 feet in length, except where turning corners or carrying the cables over railroad tracks. The poles, when fully loaded as above, are able to carry safely a weight of 4,500 pounds of cable.

The steel poles are built of four corner angles, connected together by angles and plates forming a lattice type of construction. They are tapered uniformly to the top on two sides and to within about 72 feet of the top on the other two sides, the taper being three-eighths inch per foot. This taper is uniform to the bottom of the pole and is the same for all lengths of poles. The tops are in every case six by 11 inches. At the bottom the corner angles are tied to a base composed of plates and channels, through the corners of which the four anchor bolts pass. This forms a sort of box construction around the base of the pole and greatly increases its stiffness and stability. This type of construction enables a foundation to be built and the anchor bolts set at any convenient time, independent of the delivery of the poles. This permits the most desirable degree of flexibility in the organization of the pole-setting force, thus dividing it into practically two separate gangs, neither of which is hampered by the movements of the other.

Standard poles are made in four lengths, increasing by five feet, from 39 feet to 54 feet in length, the 39-foot pole being the standard, the other lengths being used only where necessary. They are designed to withstand a wind pressure at right angles to the line corresponding to a wind velocity of 100 miles an hour.

| |||

| Fig. 4. Main Overhead Trunk Line Near Woodhaven Junction. |

POWER-TRANSMISSION LINE AND THIRD-RAIL SYSTEM OF THE LONG ISLAND RAILROAD.

Besides the standard poles above described, designed to meet the ordinary conditions, an extra-heavy pole was designed in three lengths. This type is called the strain pole and is used for offsets up to 32 ½ feet for turning sharp corners, or for anchoring the line at special points.

The size of the concrete foundation varies with the height and character of the pole. For the straight-line pole the dimensions are 4½ to five feet square, averaging eight feet deep, with 1 3/8-inch anchor bolts. For the curve poles the foundations are somewhat heavier.

Wooden poles are of two kinds — chestnut, which is the standard for ordinary work, and creosoted yellow pine, which is used only along the trestle over Jamaica Bay. The chestnut poles are 45, 50 and 55 feet in length and 25 inches in circumference at the top. The creosoted poles are from 60 to 80 feet long, with the same dimensions at the top, and treated with 15 pounds of dead oil of coal tar per cubic foot of timber. Creosoted poles are all set 15 feet into the bottom of the bay by means of a water jet. They are all set so as to have the tops 30 feet above the rails and are located far enough away on one side of the trestle to obviate any interference with the wires on the part of the pile driver that is used to renew the piles of the trestle bridge. These poles are braced to the trestle with creosoted yellow pine timber.

The total number of steel poles employed is 377, of chestnut poles 490 and of creosoted yellow-pine poles 264.

Cross-arms are of yellow pine, five by six inches cross section, housed on top to a 12-inch radius, and they are painted with one coat of asphaltum paint. On the wooden poles they are gained one inch into the pole and held by one three-fourth-inch through bolt with two-inch square washers.

The two circuits on the Jamaica Bay trestle and on the line immediately north of it were carried one above the other on two sets of cross-arms on the side of the pole, the cross-arms being flush on the side of the pole opposite to the circuits. On the trestle itself the circuits were both on the side of the pole away from the track, in order to get them as far as possible outside the sweep of the pile driver used to replace piles in the trestle bents. On the main line, to the north of the trestle, how-ever, this position was reversed, on account of the four tracks here laid. The poles had to beset as far as possible toward one side of the right-of-way, and there was not room enough to carry the wires on the outside of the pole without over-hanging the adjoining property. The cross-arms here are four feet and five feet long, but the standard bracing and fastenings are used.

Insulator pins consist of malleable-iron castings clamped to the cross-arms by means of U-bolts threaded through the body of the pin and held by a plate fitting over the U-bolts and against the cross-arm. This type was first used on this transmission line and represents a new departure in pin design, in as much as by its use all boring of the cross-arm is avoided. The strength of the cross-arm is maintained and the depreciation resulting from entrance of moisture through holes bored in the arm from top to bottom is obviated. The form of pin used is also of much greater strength than is possessed by a pin in which the bending moment where it enters the arm has to be met by small cylindrical cross section, which in case of the iron pin is sometimes not more than three-quarters inch in diameter, and in a wooden pin 1½ inches to two inches. The strongest part of this pin is at the base, where it joins the cross-arm. It admits of easily following up any shrinkage of the cross-arm (which cannot be done in a pin which is set in a hole in the cross-arm), as all that is necessary, if the pin comes loose, is to tighten up the nuts on the underside of the clevis.

The straight-line insulators are 6½ inches in diameter and five inches high, made of porcelain in two parts connected together. The insulators are colored with a brown glaze to render them less conspicuous. They are designed particularly for the conditions here imposed. The pin and insulator together carry a 250,000-circular-mil cable 6½ inches above the cross-arm. The ties are made of ordinary soft copper wire, tied on top. The tests to which the insulators were subjected at the factory include a rain test at 30,000 volts and a salt-water flash test of 50,000 volts for two minutes. The insulators were further obliged to pass the test of plunging them into hot water and then into ice water without cracking. After the insulators were erected and the cables strung upon them ready for operation they were tested by applying 30,000 volts between the conductor and the ground for four minutes. The insulators underwent all these tests successfully.

Strain insulators are of the "spool" type and made in one piece 7½ inches in diameter and eight inches high. Each strain insulator has two petticoats, one above and one below the point where the wire is attached. A 1-inch by 12-inch steel pin is cemented in the center of the insulator, and this steel pin rests in sockets at the top and bottom, which are firmly clamped by U-bolts to the cross-arms.

The insulators were cemented onto the pins be-fore erection. The cement used throughout was composed of litharge moistened with a mixture of glycerine and water. This type of cement was found after careful trials to be preferable to Portland cement, and although the materials were more expensive, it was found that the labor cost of doing the cementing and the risk of breakage were so much less as to more than counterbalance the extra cost of material.

CABLES AND CABLE RACKS.

The transmission cables are of 250,000-circular-mil stranded copper and are fastened to the insulators with ties of No. 6 copper wire, three feet long. Splices were made by cutting back the core of the cable and wrapping the outer layers of strands around the abutting cables after the manner of the ordinary Western Union splice. All the joints were soldered. Where jumpers were used to lead into sub-stations or arrester houses, the ordinary half-connection joint was made and carefully soldered.

| |||

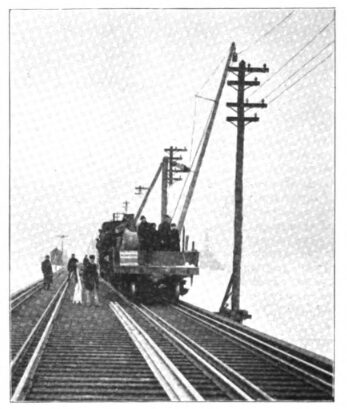

| Fig. 5. Trunk Line Poles Over Railroad Tracks, Long Island Railroad. |

The cables were strung for the most part by means of teams of horses and running lines of 1,000 feet or more in length, the cable reels being mounted on stationary stands.

On the trestle, however, this method could not be so readily followed and the cables were strung in the following manner: The reel of wire was carried on a flat car, upon which was carried a boom capable of being swung to one side to the position which would be occupied by the wires. At the end of this boom was a snatch block, through which the wire passed and by which it was guided on the cross-arm. The car was moved along slowly by a locomotive and wire paid out, the boom being raised at each cross-arm so that the wire would drop down on to the arm. This method proved very economical and is illustrated in Fig. 6. The total amount of overhead transmission cable erected is 62.03 circuit miles, or 186.09 miles of cable.

After the line was finished the railroad company installed a telephone line, which is carried on the same poles that support the power circuits and connects the power house with all the sub-stations. It also has instruments connected to it and mounted in boxes at intervals of about 2,000 feet, which are used by the men patrolling the line.

| |||

| Fig 6. Stringing Cable on Jamaica Bay Trestle of Long Island Railroad. |

At the Woodhaven and Rockaway Junction sub-stations special terminal poles or racks are provided to distribute the overhead circuits along the face of the building parallel to the high-tension switching galleries in such a manner that the disposition of the cables after entering the building will be most convenient. The conditions to be met at such places were somewhat conflicting. The disposition of the circuits on the line poles is such as to enable those on one side of the pole to be shut down for repairs, while those on the other side are kept in operation, and it was desirable in leading the cables into the sub-station buildings to adhere as closely as possible to a disposition that would be consistent with this scheme.

The sub-station galleries were laid out for the most convenient subdivision of the high-tension bus into sections for distributing power to the branch-feeder circuits, as above noted, so that it was necessary to lead certain circuits into particular openings in the side of the building without special regard as to whether that particular disposition was the most convenient for keeping the circuits clear and free from crosses outside of the building. An idea of the manner in which these conditions were met is best given by Fig. 7.

The wires of the circuits as they come from the trunk lines are brought into the same plane, the upper circuits going to the top cross-arm which is located at the rear or farthest end of the terminal pole. The next lower circuits are anchored directly in front of these, and so on, gradually working toward the front of the pole, and downward from the top of the pole as one circuit after another is added, thus obviating interference with working circuits when new ones are being erected. By an arrangement of jumpers the outside circuits are led around without interfering with other circuits and brought opposite their proper pigeon holes in the side of the sub-station structure.

TYPE OF THIRD-RAIL CONSTRUCTION.

In the selection of the general type of third-rail construction adopted for the Long Island Railroad, the general requirements were that both the rail and the contact device must be suitable for collecting heavy currents at any speed. The rail must be so placed as to encroach as little as possible beyond the fixed clearances of the permanent way, and it must clear all forms of equipment in general use on the road. The design of mounting must be mechanically stable, and besides including good insulation must provide a reasonable degree of protection to employes against accidental contact and be proof against interruption of service by weather conditions.

It was also desired to settle upon a standard form and location of rail that would permit a free interchange of ordinary passenger and freight equipment between the Long Island Railroad and other roads in the vicinity.

A study of the equipment clearances pointed to the necessity of locating the third rail with its gauge line 26 inches from the inside of the gauge line of the running rail and its top at a height of 32 inches above the top of the track rail. After considering a great variety of designs, both of rails and contact shoes, it was decided to adopt the top-contact type which is now almost universally employed. In order to best combine the qualities affording protection to employes and immunity to weather troubles it was decided to provide a horizontal type of guard extending directly over the rail, requiring the use of the slipper type of contact shoe. With this type of contact rail a tee section was naturally adopted on account of its stability. The location of the contact rail with reference to the track was also governed by the fact that it could not be placed much farther away from the track rail without interfering with bridge gussets and other fixed objects, while, if placed higher, the guard would be interfered with by 50-ton hopper-bottom steel coal cars when heavily loaded.

The rail used for most of the construction is a modified tee shape weighing 100 pounds to the yard, in 33-foot lengths. The section is four inches high, with a head three inches wide, bottom flange six inches wide, and web 1½ inches thick. This particular shape was selected because of the limited vertical distance between contact and running rail tops requiring that the upper rail be of as low section as possible to provide maximum insulation distance to tie. In some cases running rails were only 60 pounds section, reducing the available distance from the top of the tie to the top of the third rail to only 7½ inches. The section, therefore, is that of heavy rail squeezed out horizontally, with a broad base adapted to reduce over-turning. The rail is of extra-soft steel.

All of the main-line tracks on the elevated line are provided with this 100-pound third rail, excepting about 7½ miles, which are fitted with 70-pound standard relaying tee-rails. For side-tracking and unimportant spur work, 60-pound relaying rails were used.

The contact rail is supported every 10 feet on vitrified clay insulators set on extra long ties. The insulator consists of a cylindrical piece of vitrified clay with a beveled flange projecting at the base and a two-inch hole through the center to aid in manufacture. A malleable-iron ring having two projecting lugs and holes in each lug for lag screws fits over the flange at the base of the insulator, two lag screws being used to fasten it to the tie.

Resting on top of the insulator is a malleable-iron cap which projects down over it for a distance of 1 1/8 inches and has two ears 1 1/4 inches long projecting upward. The rail rests on top of the cap between the ears. With this type of insulator no vertical strain comes upon it, due to the sagging of the tie when a train passes, as the rail is in no way directly attached to it. The design also facilitates the removal of broken insulators, as the whole device may be removed by taking out two lag screws in the base. There being four different sizes of running rails and three sizes of third rails, the dimensions of the insulators are made in three sizes to suit the conditions. Two of them are six inches in diameter and 3 7/8 inches and 5 3-16 inches high, respectively, the other being 4 ½ inches in diameter and 3 5/8 inches high, but of the same general form. In this way the proper height of third rail above the running rail is maintained.

The end-approach blocks and incline for lifting the third-rail shoes are of cast iron. Two lengths are used, one being 5½ feet long and used on main-line tracks where the shoes must be raised and lowered at high speed; while the other, which is 22 feet in length, is used only on spur track and sidings. The approach blocks are attached to the end of the rails by the regular splice plates and are supported on standard third-rail insulators at their outer ends.

| |||

| Fig. 7. Terminal Cable Rack at Woodhaven Junction on Long Island Railroad. |

The third-rail joints are bonded by laminated copper foot bonds with plug terminals. They are of varying sizes, according to the weight of the rail to which they are applied, 300,000, 350,000 and 400,000-circular-mil sizes being employed. The holes for the plug terminals were punched in the base of the rail by hydraulic punches, and the terminals riveted into the holes by hydraulic compressors.

The third rail is frequently interrupted by high-way crossings and switches, and at such places underground cables are provided to maintain its electrical continuity.

As at present installed the third-rail system is not fed in separate sections from the sub-stations, but is treated as a continuous conductor between sub-stations, except where the number of switches and cross-overs incidental to a station terminal or junction necessitates dividing it into sections that can be easily isolated from the remainder of the third rail should emergency require. There are, therefore, no low-tension cables running along the tracks to reinforce points distant from the sub-stations, but the frequency of highway grade crossings and track switches and cross-overs requires the frequent interruption of the third rail. To maintain its electrical continuity at such places underground jumper cables are provided.

These cables are in three sizes — 500,000 circular mils, 1,000,000 circular mils and 2,000,000 circular mils. The cable is insulated with varnished cambric four-thirty-seconds inch thick, which is covered with a lead sheath one-eighth inch thick for the 1,000,000 and 2,000,000-circular-mil and three-thirty-seconds inch for the 500,000-circular-mil cable. Outside of the lead there is a layer of prepared paper and two layers of jute wound on spirally in opposite directions and thoroughly impregnated with asphalt. This unusual precaution is taken to protect the lead from acids and alkalis in the soil and from possible electrolytic action of return currents in the ground.

| |||

| Fig. 8. Standard Third-Rail Construction on Atlantic Avenue Elevated Structure. |

POWER-TRANSMISSION LINE AND THIRD-RAIL SYSTEM OF LONG ISLAND RAILROAD.

The Stilwell-Slater type of guard was adopted for the third rail; it consists of yellow-pine plank 1 7/8 inches thick, seven inches wide, placed above the rail, with 2 1/2-inch clear space between the top of the rail and the under side of the plank. The edge of the plank nearest the track extends seven-eighths inch beyond the line of the third-rail head and is beveled back to give the necessary clearance for running equipment. Each plank has a saw cut three-eighths inch deep in the middle of the under side to prevent warping. The planks vary in length from 14 to 16 feet. The guard is supported directly from the third rail, there being four supports to each plank. The planks are butted together without splicing so as not to interfere with the free expansion and contraction of the rail and to facilitate repairs.

Fig. 8 is an excellent view of the standard third-rail and guard construction as it appears on top of the elevated structure on Atlantic Avenue.

Additional protection is provided for the third rail at stations. This additional protection on the outer side of the rail consists of a yellow-pine strip four inches wide and 14 inches thick, set at an angle of about 45 degrees with the rail and almost completely covering the side of it.

Cables connecting the third rail with the sub-stations are of 2,000,000 circular mils and connections are made directly in front of the sub-stations. In some cases these short feeders are located in conduit and in other cases laid directly in the ground in the manner above described for the crossing jumpers. Such cables when laid in ducts are insulated with five-thirty-seconds inch of paper, covered with a layer of sheathing one-eighth thick.

Near each sub-station the third rail is interrupted by a 40-foot gap. Should any section break down it is then impossible for a single car to bridge the gap between the live rail and the grounded one, thus avoiding the possibility of injury to the car wiring and equipment. The east and west-bound tracks are in most cases supplied by a separate set of feeders and are not cross-connected, except through the station bus-bars. Current can therefore be cut off from the section of either track lying between two sub-stations simply by opening the proper feeder switches in the stations at each end of the section.

| |||

| Fig. 9. View on Main Line and Sidings Equipped With Third Rail. |

POWER-TRANSMISSION LINE AND THIRD-RAIL SYSTEM OF LONG ISLAND RAILROAD.

In order that part of a section between two sub-stations may be disconnected in case of emergency, instead of requiring the whole section to bethrown out of service, 1,600-ampere disconnecting switches are installed at suitable intervals between sub-stations being cut into the third-rail circuit, so that by opening any two of them the section between them can be cut out, though normally theses witches are kept closed. They are generally located near the cross-overs to enable trains to switch around the opened section on the other track. The switches are of the quick-break knife-blade type and are located in wooden boxes fastened to the third-rail guard.

Practically all the line is double-tracked, excepting two stretches which are four-tracked, one on Atlantic Avenue between Chestnut Street and Woodhaven Junction, and the other running south from Woodhaven Junction as far as the north end of the trestle. The third rails on the former of these two sections are supplied by separate feeders from Woodhaven Junction, and it is not cross-connected with the main-line tracks. South of Woodhaven, however, the third rails of the four tracks are cross-connected. Each of the four third rails has a separate feeder leading into Woodhaven Junction sub-station, but at the other end near the trestle the two east-bound tracks are connected together through a knife switch and a 2,000-amperecircuit-breaker, located in the switch house at one side of the track. The two west-bound tracks are similarly connected so that under ordinary conditions they work in multiple. In case of a short-circuit, however, the circuit-breaker will open, separating the tracks at that end, and this separation can be completed by throwing the switches in the sub-station.

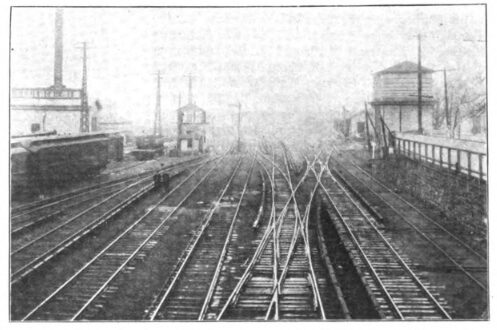

There are several very important places on the line where the arrangement of interlocking switches is such as to require special provision for cutting the third rail into sections. Woodhaven, Ozone Park, Jamaica and Hammel are points where the arrangement of intersecting and side tracks is such as to require this special treatment. Fig. 9 shows the arrangement of the third-rail circuits at a rather complicated interlocking point just east of Jamaica station.

RETURN CIRCUIT.

Both running rails of each track are used for the return circuit. On a considerable portion of the line an automatic block-signal system is used, requiring the use of both running rails for its operation, so that a special method had to be used in order to allow the tracks to be used jointly as a power-return circuit and for signal purposes. The signal system was developed by the Union Switch and Signal Company, and employs alternating current for the operation of the signals. With the aid of a special arrangement of bonding, to be described hereafter, the track is used for carrying both direct and alternating current, without the former affecting the latter.

About 20 miles of track on Atlantic Avenue is laid with 100-pound tee rails. The remaining portion of the electrified system is laid with various weights of rail, running from 60 to 80 pounds per yard.

The problem of bonding the rail joints was solved by different methods, on different portions of the line, depending largely upon the local conditions. The rails having been practically all laid when the work of equipment began, the type of joint plate then in position had much to do with the various types of bonds employed.

It was found impossible to install bonds of sufficient size beneath the splice bars already in use. Foot bonds could not be used on the elevated portions of the Atlantic Avenue improvement, because this track had supported joints, and where the tracks were laid on the surface they could not be used, because the leakage through them would unfavorably affect the operation of the signal system. On a portion of the line which has no automatic block-signal system, however, soldered foot bonds, placed underneath the rail joints, were used.

A good deal of the bonding was done with laminated bonds of the soldered type, attached to ends of each splice bar, requiring four bonds per joint.

Where the automatic block-signal system is used, it is not possible to cross-bond the running rails, on account of the disturbance in the signal system which would thereby be occasioned. On other portions of the line two 350,000-circular-mil bonds of the plug-terminal type were installed between the rails of the same track and between adjoining tracks at intervals of about 1,500 feet. A special arrangement was devised for cross-bonding a portion of the line where the automatic block-signal system is used. The cross-connections only occur at the end of the signal blocks, where the special inductive bonds are cut into each track rail. These inductive bonds serve to keep out signal current, but, for the direct current, act exactly the same as the ordinary bond, and maintain the continuity of the running rail . The cross-connections between the tracks are made at these points, the inductive bonds being used in both tracks, so that the signal system is not affected by the flow of current between them.

At the two drawbridges in the Jamaica Bay trestle the continuity of the return circuit is maintained by four 2,000,000-circular-mil rubber-covered armored cables at each crossing, similar to those used for the third-rail circuit, and connected up to the rails in like manner.

The feeder connections between the track rail and the negative bus-bar connections in the sub-stations are 2,000,000-circular-mil bare tinned copper cable. In some cases these cables are buried directly in the ground, without protection, while in others they run in vitrified-clay ducts.

CONCLUSION.

The completed overhead line was first put in service on April 27, 1905, and the third rail was the first put into service about May 13, 1905. Regular operation began July 26, 1905. The operation of the transmission line and the third rail have been remarkably free from interruptions of what ever nature, and have demonstrated their efficiency as a substantial and reliable transmission system for a suburban railroad on whose regularity of operation thousands of people are daily dependent.

The design and construction of the fore going transmission system was carried out by Westinghouse, Church, Kerr & Co., engineers for the Long Island Railroad Company, and the entire work was under the direction of Mr. George Gibbs ,chief engineer of electric traction of the Long Island Railroad, subject to the approval of an electrical committee, consisting of the chief operating officials of the road, with the president as chairman.