[Trade Journal]

Publication: American Glass Review

Pittsburgh, PA, United States

vol. 47, no. 13, p. 15-17, col. 1-2

Making Battery Jars and Carboys

At Gayner Glass Works In Salem

By S. B. Roberts

(Reproduced from the December issue of

Compressed Air Magazine through courtesy of the publishers.)

Salem, N. J., enjoys the distinction of being among the oldest of the country's glass manufacturing centers. Today, as was the case long ago, the glass industry still flourishes in this picturesque town that so pleasantly reflects the centuries that have passed since the community was instituted. The art of making glass in Salem has, therefore, been handed down from generation to generation - changing its application as each succeeding period has found new uses for the material.

Bottles constituted a predominating percentage of the products in the decades past, and bottles loom very large in the volume of commodities now turned out in Salem's glass plants. But don't let us hasten; let us review some of the conditions that made southern New Jersey for many years the source of most of the glass manufactured in America.

As far back as 1675, John Fenwicke, an English Quaker, sailed in between the Capes of the Delaware River, disembarked on the shore of what we now call New Jersey, and purchased lands from the Indians. There, he called into being the first permanent English settlement on the Delaware, and named the place Salem. Twenty years later, Salem was formally incorporated as a town.

In those days, as long afterwards, glass beads were a medium of barter and exchange between the white man and the Indian; and beads and other forms of glassware had then to be imported from abroad. Accordingly, the early settlers of New Jersey - especially those dwelling near the seacoast, soon essayed to make glass, themselves, from the abundant raw materials at hand. In doing this, they followed the example set by the colonists at Jamestown, Va., who began the manufacture of glass as early as 1609.

|

| Left - Primary Operations in the Hand-Blowing of Large Glass Containers. Top - Where Compressed Air is Used to Expand the Glass Bubble, Within the Cast-Iron Mold, That Forms the Body of the 12-Gallon Container. Bottom - at This Stage the Cooling Action of Compressed Air is Employed to Solidify the Plastic Glass. |

One has only to recall that three essential materials are needed to produce one kind of glass - those are lime, sand, and soda ash or potash. The early settlers in New Jersey found sand of the required quality in or adjacent to the nearby beaches; and they got their lime by burning oyster and clam shells, gathered from neighboring flats or water beds. For fuel, they had available seemingly inexhaustible stands of pine timber; and from the ashes of this fuel, when leached, they obtained the potash they needed. Thus, because of trade demands and consideration of their own convenience and comfort, pioneers in New Jersey brought into being a glass industry that has continued there, with varying degrees of importance, ever since.

| |||

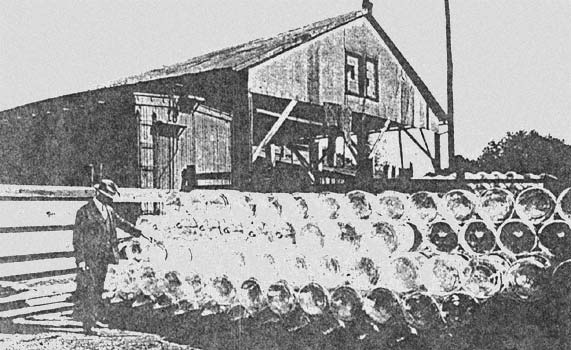

| A Lot of 12-Gallon Carboys Ready for Packing and Shipping. |

Plainly, the Gayner Glass Works, in Salem, has a historical background for its activities. That enterprise is relatively young - dating back a little more than half a centrury. To be exact, the works was established in 1874 by John Gayner, Sr., who died only a few years ago at the very ripe age of 90-odd years. So absorbed was Mr. Gayner in the business that he had created that he visited the plant almost daily up to the time of his death - in the latter years being taken there is [sic] in a wheel chair. The business is now directed by his some [sic] son Edward J. Gayner, the president of the company.

DIFFERENT SOURCES OF POWER

The plant is engaged in the manufacture of what is known in the trade as "large ware," consisting principally of large bottles, carboys, battery jars, etc. In the course of its career, the Gayner Glass Works has relied upon different sources of primary power - steam, produced with coal, predominating for the most part. And in blowing or molding its ware, the plant for a long time depended on the lungs of its workers; and only in recent years, so to speak, has the management found it advantageous to have recourse to compressed air for various purposes. Similarly, coal and gas have been utilized to provide heat for the melting tanks; and today compressed air and fuel oil are employed to heat molds and the small furnaces or "glory holes" in which the glass is reheated during different stages in the blowing and forming of the ware. These facts are mentioned so that the reader will realize that the Gayner Glass Works has, in its way, reflected the march of engineering in the generation of power and heat. The latest innovation in the plant has been the introduction of an oil-engine-compressor unit to furnish compressed air for numerous services throughout the different departments of the establishment.

Until three years ago, all compressed air used in the plant was supplied by two steam-driven machines, each having a piston displacement of 654 cubic feet per minute. Both of these units were Imperial Type 10 compressors manufactured by the Ingersoll-Rand Company. Work actually in hand, and other developments under advisement called for more compressed air; and the management was confronted with the problem of choosing another steam-driven unit or some other type of compressor. With operating economy the objective, combined with the need of a machine of greater capacity, the decision - after a survey of the field - was made in favor of an oil-engine-driven compressor of the well-known POC-1 Type. This machine, built by Ingersoll-Rand Company was duly installed in 1924; and the unit has a piston displacement of 802 cubic feet per minute - the discharged air going into the service line at a pressure of 45 pounds per square inch. In other words, the POC-1 machine furnishes about 25 per cent more air per minute than either of the steam units.

Apart from a record of satisfactory service over the three years intervening since the oil-engine-driven compressor was added to the equipment of the Gayner Glass Works, the president of the company, Mr. Edward J. Gayner, has recently said of it: "The unit is absolutely reliable. It has caused less trouble and has taken less care than any other machine on the place." Furthermore, Mr. Gayner states: "The POC-1 costs approximately only one-third as much to operate as either of the steam compressors." This comparison is made on the basis of total costs, and includes fixed charges as well as operating costs.

|

| Oil-Engine Compressor That Furnishes A Considerable Percentage of the Air Used in the Gayner Glass Works. |

Before describing how compressed air is utilized in the Gayner Glass Works, and before touching upon some of the manufacturing methods of the plant, it might be of general interest to mention what that establishment produces in the course of a year. The output, for the most part consists of 150,000 carboys, each capable of holding 12 gallons of acid; 300,000 bottles, each of 5-gallon capacity; and substantially 500,000 battery jars. While the plant does make some Jericho ware - that is, bottle ranging in capacity from half a pint to one gallon, still most of the smaller containers turned out average half a gallon in capacity. In brief, this widely known glass works takes up the making of containers where most other plants leave off, and, therefore, is notable because of the larger sizes most of the bottles and carboys produced by it.

In the manufacture of battery jars the Gayner Glass Works took a leading place some years ago; and it has maintained its position in this business by developing special machinery for the purpose - compressed air helping to make the performances of these machines successful. We are not permitted to describe these apparatus. Glass battery jars are extensively employed for storage batteries in all kinds of service.

PROCESS OF MANUFACTURE

It will probably interest many of our readers to learn how large carboys and water bottles are made in the Gayner Glass Works. At Salem, both human lungs and power-driven compressors provide the air which transforms the gob or gather of glowing plastic glass in blowing the containers with which we are generally familiar. Compressed air does the double service of helping to model the glass and then to harden or set it so it will retain the desired shape. Perhaps this can be easiest understood if we follow the stages by which a single five-gallon bottle is made.

First, the operator gathers on his blow pipe or iron - from a tank filled with molten glass - a quantity of glass, and rolls this on an iron plate. Then he goes back to the tank to add more glass until he has accumulated on his pipe enough of the incandescent plastic material to make a carboy. With this achieved, he blows into his iron and produces an initial bubble in the yielding glass. Next, he slips a hose over the mouth of his pipe and turns on compressed air to increase the cavity and, incidentally, to enlarge the bubble of yellow-hot glass. By now the glass has cooled somewhat and stiffened slightly, so that the bubble must be reheated. This is done by putting the glass in a small furnace, called a 'glory hole," that is heated by fuel oil sprayed or atomized with compressed air.

When sufficiently reheated, the bubble is worked on an iron table in a pit - the blower's pipe being held vertically and rotated the while. This operation forms approximately the bottom of the bottle. While revolving the glass on the table, the worker blows with his mouth into the bubble. Everything is now ready to shape the body of the bottle. This is effected by putting the yielding glass into a split iron mold that is kept at the right temperature by heating it with a flame produced by oil sprayed with compressed air. When the glass in enclosed within the mold, compressed air is blown down through the attached pipe, forcing the plastic mass against the walls of the mold.

After being removed from the mold, the body of the bottle is cooled to rigidness by a stream of compressed air, and then the ware is again reheated in a "glory hole." When it has been heated to a suitable degree, the bottle is withdrawn and the neck length is formed by revolving the attached iron and by gripping the neck mass with hand-held finishing tools. The tools used by the glass blower are lubricated with powdered carbon and rosin; and the forming block on which the bottom of the bottle is shaped is lubricated with sawdust. With most of the neck thus fashioned, the bottle is skillfully detached by the blower from the rest of the glass still adhereing to the blow pipe - the finishing lip of the neck being formed by the next or concluding operation.

When a bottle has thus been produced, it is promptly put into an annealing furnace or lehr, where a moving platform slowly carries it from one end to the other - the temperature increasing or decreasing gradually during the journey. In this way, any internal stresses in the glass - set up during different stages of forming - are released or neutralized, and the bottle is therefore stronger and less likely to break when exposed to a considerable range of temperature in service. The lehr is heated by fuel oil sprayed with compressed air, and the melting tanks are heated with a mixture of air and producer gas. This gas is made in the plant by producers using gas coal.

Glass making is a continuous activity; and continuous tanks are used to melt the batch which is made up of lime, soda, sand, arsenic, and a certain proportion of scrap glass or cullet. The raw materials are fed into one end of a furnace in which they are melted and refined, flowing on to the outlet end of the tank where the glass is withdrawn to be blown either by hand or by machines. Where machines of this description are employed in the Gayner Glass Works, they are operated either in part or entirely by means of compressed air.

The actual blowing or machine-making of the glassware begins on Monday morning at 7, and goes on night and day until 4 o'clock of the following Saturday. The furnaces are kept heated continuously from the time of starting operations - including Sundays and holidays - until any of them is shut down to be rebuilt or to receive major repairs.

Before a container leaves the Gayner Glass Works it is tested to make sure that it is sound. Any structural weakness is quickly detected by tapping the bottle or carboy. The experienced ear can tell by the resulting ring whether or not the ware is all right.