[Trade Journal]

Publication: Journal of the American Ceramic Society

Columbus, OH, United States

vol. 5, no. 8, p. 492-499, col. 1

THE HARROP TUNNEL KILN

BY W. E. CRAMER

ABSTRACT

The successful application of the car tunnel kiln to the firing of electrical porcelains is described. This kiln is 321 feet long, 54 1/2 inches wide inside, and has a placing height of approximately 60 inches. Ware has been fired through this kiln in 48 hours-total time for heating up, soaking, and cooling. The kiln operates at cones 10, 11, and 12, depending upon the ware being fired. Natural gas is used as fuel and is supplied to the kiln through Maxon Premix burners. Auxiliary fuel oil equipment is also installed. The ware is placed in saggers as formerly.

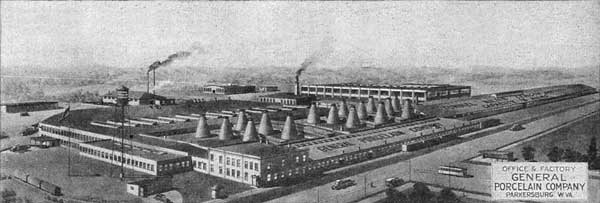

The tunnel kiln located at the plant of the General Porcelain Co., Parkersburg, W. Va., is a Harrop kiln of the direct fired type and is firing low tension electrical insulators, special porcelain and a general line of standard electrical porcelain. It is equipped for burning either fuel oil or natural gas or the two fuels can be used together. The kiln is so constructed that with a few minor changes in the furnaces, coal can also be readily used for fuel.

Construction on the kiln proper was started on March 4, 1921, and it was completed on July 14, 1921, at which time it was started in operation.

The kiln is housed in a Milliken fabricated steel building which is 60 feet wide and 350 feet long. This building is bolted together throughout having steel window sash, steel doors and concrete floor which makes it an ideal kiln building.

The kiln is 321 feet in length and the inside width is 54-1/2 inches. The overall height is approximately eleven feet. Of the 321 feet in length, 160 feet is taken up in the heating up zone, 42 feet in the firing zone and 119 feet in the cooling zone. The firing zone includes eight furnaces, four on each side of the kiln, which are in staggered relation.

The kiln car is six feet long and 58-1/2 inches in width, the effective setting space being fifty and one half inches by five feet nine inches. The metal parts of the car are protected from the high temperature by sand seals which extend the entire length of the kiln. The cars are propelled by an automatic hydraulic ram.

The burners used on the kiln are the Maxon-Premix type. They are so arranged that either gas or oil can be used and a change can be made from one fuel to the other at a moments notice. .If desired both fuels could be used together.

The total power required to operate the kiln is twenty-one motor horsepower. This represents the motor horsepower provided but it is calculated that only about eighty per cent of this power is used under normal operation.

There are four firemen required to operate the kiln, in two turns of twelve hours each with two men on each turn. These men attend to charging the cars in the kiln, removing them from the kiln, and also the regulation of the heat which requires attention when there are three different firing temperatures used. . That is, in firing three different kinds of ware the kiln must operate at either cone 10, 11 or 12 and be quickly changed from one temperature to another. This change can be easily made by regulating the burners and the car schedule in from one to two hours.

|

| |||

| Charging End of Kiln Showing Loaded Cars. |

The kiln has been operated at a car schedule as fast as fifty minutes and as slow as one and three quarter hours. When operating at a one and one half hour schedule or slower it is sufficient to fire two furnaces on each side of the kiln to obtain good results, but a faster car schedule requires the use of three furnaces on each side.

The entering temperature of the kiln varies between 100°F and 220°F. The heating up curve is practically a straight line until it reaches the burning temperature of cone 10, 11 or 12. Then the temperature drops off quickly and then more slowly as it nears the end of the kiln. The discharge end temperature varies' between 175ºF and 350°F.

The cooling air is first drawn under the cars from the atmosphere by means of a suction produced by the air supply fan. From under the cars it is drawn through the fan and tempered with atmospheric air and then divided three ways. Part of it is forced into the discharge end of the kiln and serves for cooling the ware. The second part is forced through a flue over the entire discharge end of the kiln from where it is led down over the furnace arches and delivered into the furnaces as secondary air for combustion. The third part is circulated through hollow walls in the furnaces where it is preheated and then can be led to the burners or forced through the grates as primary air for combustion. The temperature of the air as it comes from under the cars has been found to be 340°F when the kiln was operating at cone 12. As this same air enters the discharge end of the kiln after being tempered its temperature is 165ºF.

The combustion gases leave the furnaces and enter directly into the tunnel proper, travelling horizontally toward the charging end. Near the charging end they enter flues in the side walls of the kiln and are taken out by the draft fan. The temperature of these gases as they enter the stack is 350°F.

The cross-sectional heat distribution has been excellent. At times the tops of the car setting has been about one half of a cone easier than the bottoms. However, this has been easily remedied by the proper adjustment after which practically every sagger on the car received the same temperature. In August, 1921, a car loaded with one hundred and twenty five-inch saggers, every one containing cones and ware trials, was run through the kiln in order to determine the cross-sectional heat distribution. It was found that each sagger received practically the same amount of heat, there being but a quarter of a cone variation throughout the entire setting.

| |||

| Discharging End of Kiln. |

The top saggers of the setting were slightly easier than the bottom saggers. Later it was found that, unlike other kilns of the car tunnel type, it was possible to maintain continuously a higher temperature along the bottoms of the setting than along the tops. This condition is undoubtedly due to the construction of the inner walls of the kiln which allows an easier passage of gases through the bottom of the setting. This is an exclusive feature of the Harrop Kiln. The car setting is three bung wide and the center bung is as well fired as the two outer ones. It was found that the same results were obtained when the saggers were set tight across the car but with a space between them lengthwise as when the setting was very loose. This again shows that there is good circulation throughout the kiln.

|

| Typical Cross-Section |

The kiln was designed to have a maximum capacity equivalent to the drawing of twelve sixteen foot diameter periodic kilns per week. Using thirteen and one half inch diameter round saggers it requires seventeen kiln cars of ware for the equivalent of one periodic kiln. Thus a fifty minute schedule will give the above capacity. Using square saggers the amount of ware placed on a car can be increased by 55%. These saggers are now being made and will undoubtedly increase the saving and efficiency of the kiln.

The kiln will hold fifty-two cars in its length. Thus at an hour schedule a car will remain in the kiln fifty-two hours, twenty-six hours being used in the heating up zone, seven hours in the firing zone and nineteen hours for cooling. This gives a saving of approximately 35% in firing time over the periodic kilns.

It is interesting to note that the average weight of one car loaded with green ware ready for the kiln is slightly over ten thousand pounds, the weight of an empty car being four thousand pounds. The pusher is of ten tons capacity and to propel the fifty-two cars is required but nine thousand four hundred pounds total pressure.

A fuel test conducted during the summer of 1921 shows a fuel consumption of 195,300 cu. ft. of gas in 36 hours with a production of 33 cars. At this time six furnaces were under fire. This gives a consumption of 5,580 cu. ft. per car or (94,869 cu. ft. for the equivalent of one periodic kiln. Another test was conducted while four furnaces were under fire. Twenty-four cars were produced in thirty-six hours and 130,000 cu. ft. of gas was consumed. This is 5,416 cu. ft. per car or 92,972 cu. ft. for the equivalent of one periodic kiln. Meter readings taken during the month of November, 1921, show that the average gas consumption per hour on an operating schedule of one hour and twenty minutes is 4,200 cu. ft. of gas. This shows a considerable saving over the periodic kilns.

During the five and one half months that the kiln has been operating it has been found that there is a saving in labor amounting to the elimination of one man in placing and one man in drawing the equivalent amount of ware in a periodic kiln. The odd work around the kiln is practically the same as around a periodic kiln. However, there is the elimination of maintaining the bags, cleaning out the flues and building up the doors.

There have been practically no repairs on the kiln since it was started. One of the thermocouple welds broke but it was rewelded and replaced. Twice through carelessness it was necessary to shut the kiln off for several days. One time the fireman went to sleep and let the cars stand too long, resulting in a wreck. From the time the kiln was shut off until it was back up to temperature it was but eighty-four hours, during which time the temperature did not fall below 800ºF. Another time through careless regulation of the burners a bung of saggers was caused to fall, thus requiring another short shut-down.

The kiln has shown its advantages over the periodic kilns. First of all it produces a uniformly fired product which is impossible in the periodics. It has a large fuel saving over the periodic kilns. It also has enabled a lower individual labor cost due to the fact that all placing and drawing is centralized and much easier than in the other kilns. Finally it has proved a pacemaker for the entire plant. That is, when the tunnel is operating at a certain schedule the other departments know that they have to handle a certain quantity of ware in order to keep up.

The installation cost of the kiln was considerably less than the cost of the number of periodic kilns necessary to give the same production. Due to business conditions the kiln was closed down the latter part of December, 1921, for a couple of months. Upon cooling a close inspection was made of the kiln. It was found that but few small cracks had developed on the outside of the kiln as a result of cooling. The inside of the kiln was in perfect condition after having been in operation five and one half months. It was particularly noticeable that the expansion joints had functioned perfectly.

COLUMBUS, OH