[Trade Journal]

Publication: Glass Industry

New York, NY, United States

vol. 16, no. 11, p. 333 -336

GLASS MAKING IN SOUTHERN CALIFORNIA

By Roy E. Swain

The story of glass manufacturing in Southern California is one that is closely linked with the amazing mushroom-like growth and development of this fertile section of the United States.

Fifty years ago, Los Angeles was a town with barely 10,000 inhabitants surrounded by a number of ranchos whose boundaries are still in existence. In the past 50 years, figures for each succeeding census, with the exception of World War years, have more than doubled those of the previous census. Two thirds of the present population came to California after the World War and there are now more than 3,000,000 people living within a radius of 150 miles of Los Angeles. The completion of the Colorado River project will offer opportunities to twice as many more people.

The earliest settlers were adventurers and pleasure seekers who had no interest in the development of industries. They were followed by a more serious-minded group who brought their worldly belongings with them to build a home for themselves and their families in the pleasant climate of Southern California. They would buy a small tract of land and set themselves up as orange growers or chicken ranchers or in any other business that did not require great capital or precise skill. None of them went into the business of manufacturing glass; for this would require special highly developed equipment, raw materials of known purity, and a delicately balanced organization of highly trained men. The immediate result of this influx of people from all over the United States was a tremendous building boom in the vicinity of Los Angeles, shortly after the World War. In 1923, the city of Los Angeles alone issued building permits totaling over $200,000,000, and in that and the four years following more than a billion dollars worth of construction was done in Southern California. Building regulations required a high percentage of window area based on the floor space and architects, there being no heating problem, not only used windows for lighting and ventilating but for decorative purposes as well. To furnish all of these new buildings required lighting glassware and table glassware, not to mention all of the containers and glass specialties that are part of modern living.

|

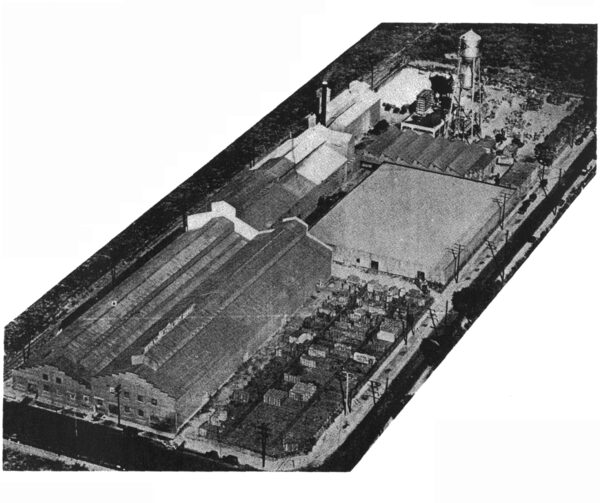

An airplane view of Los Angeles plant number 23 of the Owens-Illinois Pacific Coast Co.

Hundreds of miles of broad highways were being built and these were bordered with the latest lighting units attached on concrete or metal standards. Along these highways sprang up thousands of service stations, some of them with as many as 24 of the visible type glass pumps displaying in their glass cylinders the various colored gasolines developed to distinguish the different brands.

Concurrently, the fruit and vegetable canning industry of Los Angeles, which has been turning out a product valued at more than $5,000,000 yearly, is utilizing glass more and more for its containers. Pickles, jams, nut meats, peanut butter, and salad dressings, not to mention chicken, ravioli, tamales and pickled pigs feet, are being packed in glass in the Los Angeles district. Large quantities of fruit juices and syrups demand bottles to take them to market. And the recent comeback of the California wine industry with its promise of still further development offers a rich opportunity to enterprising bottle manufacturers.

Here was certainly a need for glass for housing, tableware, transportation and containers. And California, being a long way from most other glass-making centers, it seemer [sic] seemed profitable to make glass there rather than ship it by railroad. But at any rate, here was the demand.

Raw Materials. Southern California has abundant raw materials for the manufacture of glass. Glass being about 70 per cent silica and California being three parts sand, there is plenty of sand of which all types of bottle glasses and colored glass for other purposes may be made. For very high grade flint and crystal, either Illinois or Pennsylvania sands are used. Sand from Belgium is also used, being imported to this country as ballast. The chemical analyses and screen tests shown in the adjoining column are typical of three sands which are widely used in Southern California.

Other raw materials may also be found in Southern California. Limestone of exceptional quality is found in ten of the southern counties, and a number of these deposits are suitable for glass. Inyo county offers a deposit of dolomite. There are also deposits of quartz of very high grade but the expense of crushing and screening has made its use for glass prohibitive. The discovery of borax did much to make Death Valley famous, but more accessible deposits have been found in Searles Lake, Owens Lake, San Bernardino and Inyo counties. This borax is refined by the American Potash & Chemical Co., Pacific Alkali Co. and the Pacific Coast Borax Co. Dense soad ash is prepared by the Pacific Alkali Co. and the Natural Soda Products Co. from deposits in Inyo county and San Diego.

|

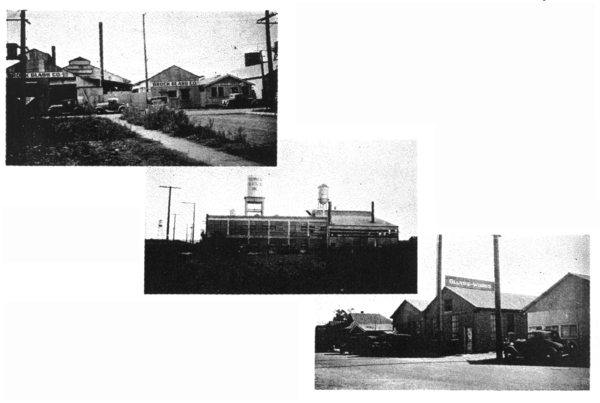

A trio of Southern California glass plants, Brock, Technical and A. H. Forger companies.

The glass and pottery trades find an ample supply of feldspar in San Diego and Inyo counties. Deposits of potash, barium, fluorspar and lepidolite are being worked in Southern California, and these materials will no doubt be available to the glass manufacturer.

|

Fuel. Almost as important as the raw materials themselves in such an industry as glass-making are abundant facilities for cheap fuel. Southern California has a plentiful supply of natural gas with a rating of 1100 to 1125 b. t. u. per cu. ft. This gas, at the time of writing, is available for industrial purposes at 15 cents per thousand cubic feet and can be had at 12 cents per thousand when subject to certain emergency regulations. Its price is controlled to some extent by the price of fuel oil which has sold for a number of years at 65 cents per barrel of 42 gallons.

Here were raw materials and fuel and a climate that provided ideal working conditions. Freezing weather* was unknown and on the hotest summer day there is always a cooling breeze off the ocean. Here seemed to be the opportunity of a lifetime. Glass factories sprang up on all sides. They ranged from small daytanks in back yards to well-financed and well-planned factories. At one time there were 35 in the Los Angeles district and failures were so common that investors were warned to beware of glass factory promoters. These plants, however, did serve to train men and to make extremely vivid the requirements for manufacturing glass.

|

(Left) End of blowing room, Latchford Glass Co. (Right) The Maywood Glass Co., founded in 1929.

One of the primary difficulties during this pioneering period was the labor situation. There were simply no highly trained glass technicians and workmen available. As a matter of fact, the labor situation in Southern California, even today, is unique. There is a great deal of cheap foreign labor available but it is confined chiefly to the many large-scale agricultural projects, whereas the majority of the industrial plants are comparatively small and employ a very high percentage of native white labor. The school census of Huntington Park, one of the residential sections of the industrial district (see map), shows that 97 per cent of the school children are of American born white parents. This ratio does not vary greatly as in the other industrial sections of Southern California. The fact that this skilled labor is paid according to the national wage scale, when combined with low living expenses, makes for a very happy labor situation. However, the low foreign labor costs concern only a few situations where unskilled labor is usable.

As a matter of fact, one of the chief causes of the early failures of glass companies in Southern California was this lack of skilled workmen. Dr. R. D. Tiffany, when appointed to straighten out the finances of a small flint glass factory located in Newport Beach, immediately sent East for skilled workmen and his call was answered by Wm. A. Anderson, Fred Glassen and Gus Conradsen.

They found that their predecessors were attempting to produce good glass in a poorly constructed melting unit made of inferior materials. They abandoned this site and organized the West Coast Glass Co., nearer the market, to manufacture a general line of pressed and blown glass. However, the demand for milk bottles was so great that the entire plant was soon devoted to them.

Glass Containers. The entire history of glass-making in Southern California appears to be based on the enterprise of a few men with their changing affiliations and the organization of new manufacturing units. Thus, Wm. A. Anderson and his associates, shortly after organizing the West Coast Glass Co., formed the Technical Glass Co., and securing a small building, started making glassware of all types. This was in 1919. Then came the great Los Angeles building boom which demanded tremendous quantities of glass for builders' hardware and the company was forced to move into larger quarters. Today, they make an extensive line of flint glass as well. Besides considerable private mold work, they manufacture a number of staple lines such as bird baths and seed cups, glassware for fountain dispensers and vending machines, ashtrays and novelties. They have also recently added more than 100 new drinking glasses to their line. Their melting equipment consists of two continuous tanks and four day tanks in which opal, black, crystal and a large variety of transparent colors may be melted.

Equally enterprising was William McLaughlin who started a bottle factory in his backyard with the assistance of a small tank and two helpers. He was, however, able to convince William J. Latchford that bottle-making had commercial possibilities and the Southern Glass Co. was organized with a group of highly trained engineers and salesmen to produce bottles and containers. In 1920, two years after starting the Southern Glass Co., McLaughlin withdrew and started the McLaughlin Glass Co. for making hand-made water bottles. A line of gallon, half gallon, beer and liquor bottles are made in flint, amber, light and dark green. There are three 15 ton and two smaller continuous tanks as well as a small day tank in this plant.

The McLaughlin Co. was also building up the production of flint glass for which there was a large local demand. Two insulator presses, six side lever presses, a press and blow machine and specially built machines made up their equipment for this. The blow furnace and swing hole are used by a pair of well-known window glass workers, Gaston and Franz Cornell, in the making of large cylinders, fish globes, garden furniture and moving picture properties.

While McLaughlin was developing his own business, Mr. Latchford concentrated his efforts on the Southern Glass Co. until 1925 when he resigned to start the Latchford Glass Co. with his stepson, Baird Marble. They located on one of the main trucking routes to the harbor, having selected enough land to enable him to more than double his plant and production facilities as the bottle business in the West grows. In the main plant, there are today three continuous machine tanks of 45, 35 and 20 ton daily capacity. The hand tank has a daily capacity of 15 tons. The forming equipment consists of five Hartford-Empire feeders and five Lynch R machines for the production of liquor, beer, vinegar and bleach bottles as well as jars for jams and pickles. The hand plant makes five-gallon water bottles. Testing laboratory, three large warehouses, all-steel factory buildings — all sprang from a small tank in Wm. McLaughlin's backyard.

This period, which saw the establishment and development of the great Latchford and McLaughlin glass companies, also wrote the final chapter for Southern Glass Co., In 1930, it was taken over by the Owens-Illinois Pacific Coast Glass Co., which closed down the plant and removed the equipment. This brought to an end the story of the plant that had first demonstrated the possibility of bottle-making in Southern California and trained so many glass men for "local experience."

Another graduate of the old Southern Glass Co., Benjamin H. Koons, in 1929 organized the Maywood Glass Co. to manufacture preserve jars and a large variety of flint and amber bottles ranging in size from eight ounce to one gallon capacity. It has one 15 and one 30 ton tank. In addition to semi-automatic equipment, the company operates two feeders under a Hartford-Empire license and the forming equipment consists of one Lynch R, one Lynch LA, one O'Neill and two Teeple Johnson machines.

Another branch of the Southern California glass container industry is exemplified by Glass Containers, Inc., which was organized in 1919, a contemporary of the Southern Glass Co. This group began as the Long Beach Glass Co. with a plant in Long Beach but they later erected another plant in Los Angeles where they moved their offices, holding the Long Beach plant in reserve. This plant is devoted exclusively to the manufacture of flint glass bottles and containers for proprietaries, ethicals, beer, liquor, toilet articles and cosmetics. They have a daily capacity of 75 tons from two continuous tanks. Their equipment consists of four Hartford-Empire feeders and the following bottle blowing machines: one Lynch B, three Lynch LA, one Lynch 10 and one Miller press and blow telescopic.

Through a series of absorptions, the Owens-Illinois Glass Co. has succeeded in establishing itself in Southern California as the Owens-Illinois Pacific Coast Glass Co. First, there was the West Coast Glass Co. which was built in 1920 to manufacture hand-pressed and blown wares. Soon, however, the demand for milk bottles absorbed the facilities of this plant which was then sold to the Pacific Coast Glass Co., which in its turn became a unit of the Owens-Illinois Pacific Coast Glass Co. Unlike the Southern Glass Company's plant, this factory continued in operation and today the greater portion of the milk bottles used in the Southwest are said to be made there. This plant recently installed a decorating lehr and other equipment for applying permanent labels and trade-marks on milk bottles.

Window Glass. The story of the window glass business varies somewhat from that of the flint and bottle business in that more than 30 years ago there was established in Stockton an 18 blower plant that was later increased to 36 blower capacity. This plant operated until 1921 when it went the way of all hand plants faced with the competition of machine factories for producing flat drawn glass.

|

The only sheet glass plant in Southern California, that of the Mississippi Glass Co.

As a matter of fact, there is only one sheet glass plant operating in Southern California at the present time, that of the Mississippi Glass Co. The reason for the failure of the window glass companies appears to be that while the bottle manufacturer usually lists hundreds of items and the flint glass maker may have thousands of items, the sheet glass manufacturer makes up a few stock sizes from which the dealer cuts his customers' wants. For another thing, sheet glass nests perfectly, thus making possible the packing of considerable quantities in a limited space. Thus economic shipping and storage are facilitated which helps to explain to some extent why the California window glass factories were forced to close down despite the very active market demand during the housing boom in Los Angeles.

The only active plant at present is that of the Mississippi Glass Co. This plant was originally erected in 1924 by the Western Glass Co. and then became a part of the Highland Western Glass Co., before being acquired by Mississippi who also have leased the plant of the Columbia Glass Co. The Mississippi Glass Co. plant has one furnace of 50 ton daily capacity and makes rolled, wire and polished wire glass for building purposes.

|

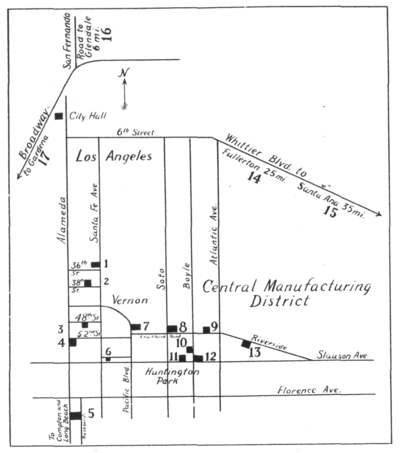

1. Glass Containers, Inc; 2. Lenwood Specialty; 3. Technical Glass Co; 4. McLaughlin Glass Co; 5. Latchford Glass Co; 6. A. H. Forgar & Co; 8. Owens-Illinois Pacific Coast Co; 11. Columbia Glass Co; 12. Owens-Illinois Pacific Coast Co; 13. Maywood Glass Co; 14. Mississippi Glass Co; 15. Brock Glass Co; 16. Crystalite Products Corporation; 17. Larson Glass Co.

To date, no efforts have been made to manufacture plate glass in Southern California, although in 1928 the Pittsburgh Plate Glass Co. bought a 200 acre plot near Santa Ana for the purpose of erecting a plant. However, business conditions have not made this advisable.

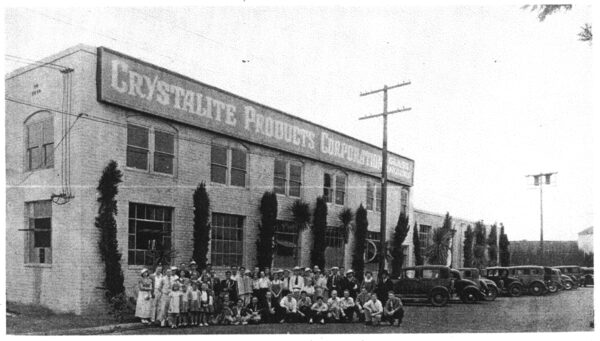

Miscellaneous Glass. In addition to producing glass containers, and some sheet glass, Southern California is also the location of manufacturers of various items made of glass. The Crystalite Products Corporation, for instance, manufacture letters for theatre advertising and lighting units. This company, with five day tanks, manufactures various glass specialties, and private mold work, as well as enclosing globes, under the supervision of Fred Glassen, who it will be recalled was one of the first glass technicians to come to Southern California.

There are various other plants making such specialties as gasoline cylinders, bird baths, residential lighting units, silvered reflectors, ironmold and pastemold and various pressed glass specialties. Among such plants are A. H. Forgar Co., Brock Glass Co., and Larson Glass Co.

One of the most interesting features of the Southern California glass industry is its concentration in a comparatively small centralized territory. Due to trucking, shipping and freight facilities it is found advisable for the industries of Southern California to centralize their activities between Los Angeles and Long Beach. The accompanying map admirably illustrates this condition.

There is still an enormous amount of glass shipped into Southern California for building purposes and household use. But when one considers that 16 years ago the business of glass manufacturing in this district was all but a total loss, the growth and present condition of the industry is remarkable. The bottle and blown containers industry has been developed with a view to an increased population in the future and the development of food and wine industries of Southern California. Certain lines of flint glass have not only been developed to take care of local needs but are shipped all over the world. However, it should be noted that only a small percentage of the tableware and lighting equipment is made in local plants. And in the field of flat glass, only rough rolled and wired glass is made in Southern California.

The 20 odd plants in Southern California employ approximately 1400 people but in normal times would probably require more than 2000. To meet present conditions, some plants have spread employment by working their plants on a four shift basis, while others are operating on a five day week.

|

Illuminating ware and novelty glass are made by hand at the Crystalite plant.