[Trade Journal]

Publication: American Electrician

New York, NY, United States

vol. 11, no. 12, p. 582, col. 1-2

LOCKE INSULATORS.

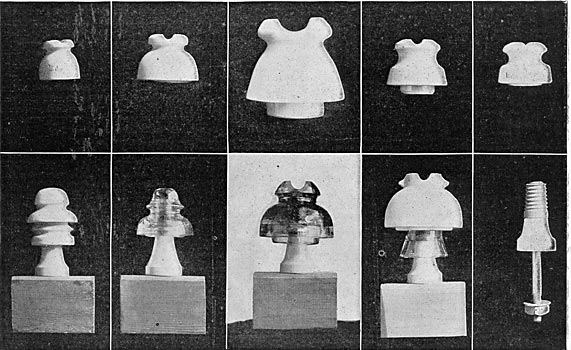

In the manufacture of insulators for very high voltages the material used must not only have a very high specific resistance and dielectric strength to resist the tendency of the current to break through it, but it must interpose a large creeping distance to prevent the current traveling over it and must provide a considerable gap between the edge of the bell and the pin to prevent the current sparking across from the wet exterior to the pin and charring and setting fire to the latter. These various considerations, combined with the peculiarities of china, porcelain and glass making, constitute the construction of insulators a fine art. The ways in which some of the difficulties of the problem have been overcome by one maker are illustrated by the accompanying reproductions, Fig. 1, of several styles of insulators made by Mr. Fred M. Locke, Victor, N. Y.

| |||

| Fig 1. - Views of Various Forms of Locke Insulators. |

|

| Top Row (Left to Right): Pony Porcelain Insulator With One Petticoat for Telephone Lines. Pony Double-Petticoat China Insulator. Street Railway Top Groove Cable Insulator, Two Parts. Street Railway Porcelain Insulator Side Groove for Standard Pin. Street Railway Cable China Insulator for Heavy Work. Bottom Row (Left to Right): Porcelain Transposition Insulator. Glass Insulator for 5,000-Volt Lines. Glass Insulator for 20,000-Volt Lines. Porcelain and Glass Insulators for 25,000-Volt Lines. Pin for Street Railway and Heavy Line Work. |

In the first place the insulator, when used for heavy work, at least, is mounted on a steel pin such as is shown in the lower right-hand corner of the illustration, and the upper part of this pin is capped with wood to prevent the breakage of the insulator through the difference between the expansion of iron and the material used in the bell. Below the wood is a porcelain sleeve which surrounds the pin and rests upon the top of the cross arm. This porcelain acts as a protection against sparking from the shell of the insulator to the pin and greatly increases the sparking voltage. The use of this pin may be seen in the other illustrations of the lower row. That to the extreme left is a transposition insulator, while to the right of it are shown porcelain and glass insulators for various voltages.

In the upper row are shown various forms for street railway use. Some of these are made in two parts, which are burned together in the second heat when the glaze is put on. This gives an extra resisting wall, which must be broken down before the current can leak through, besides which this form of construction makes each part of a more uniform thickness during the first heat, when the different rates of shrinkage of parts of different thicknesses would tend seriously to set up serious initial strains which would greatly weaken the resisting powers of the insulators to the strains of service.