[Trade Journal]

Publication: A Handbook of Practical Telegraphy

London, England

vol. 8, p. 139-150, col. 1

344. In the earlier telegraphs great care was taken to protect insulators from rain by wooden roofs; but it was found that such coverings are not only useless, but injurious. They do not themselves insulate, they afford no protection in fogs or continued rain, for then every part becomes equally damp. They harbour spiders, which spin their webs over and among the wires. All coverings hinder the drying of the supports, and prevent the rain- washing off the dust which covers the insulators; for as damp dirt conducts far better than a film of clean rain-water, insulation is often improved by heavy rain.

It is therefore inadvisable to place insulators under railway bridges, or in any situation where they will not be fully exposed, or to cover them with iron hoods, unless as a protection against stone-throwing. When hoods are needed, they should be made with slits to admit rain and wind.

The insulator should be fixed above, not under the arm which carries it, for when placed underneath, the portion which is covered by the arm does not get washed by rain.

345. Complete exposure is most of all desirable on the sea-coast. It is true that a cover may protect an insulator from the direct effect of spray, but during storms the air is impregnated with water holding salt in solution. The next shower washes the salt from the exposed surfaces, but cannot reach the covered portion ; so that the latter retains a coating of salt which remains constantly damp. It is so difficult to obtain good insulation in a line near the sea, that the coast is avoided as much as possible.

346. An insulator of suitable material conducts (practically) entirely by the film of moisture or dirt which adheres to its surface, and obeys the ordinary law of resistance. So that the best insulator is one which has the smallest possible diameter consonant with strength, with the greatest distance between the wire and the bolt or support; and which can, moreover, be maintained in the driest condition in wet weather as regards its inner surface, while exposed freely as regards its outer surface to the cleansing action of rain. It must not depend for insulation on its glaze alone, but the ware must be perfectly nonconducting.

|

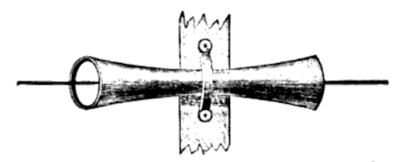

| Fig. 61. |

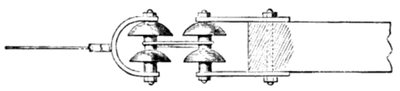

347. The dice-box or double cone form in which the wire passes through the centre (Fig. 61), and the shackle (Fig. 62), permit the current to escape in two directions, thus doubling the conducting surface, and are in consequence bad insulators. To lessen the loss two shackles are generally fixed together, as in Fig. 62.

|

| Fig. 62. |

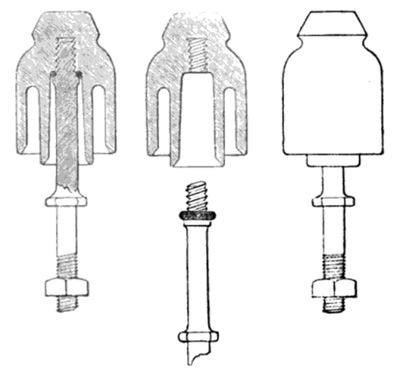

When the insulator is fixed on an iron pin which does not pass through it, the current can escape only in one direction; and when made in an umbrella or bell form, either single-shed with one cup, or double-shed with two cups, one within the other (Fig. 64); the formation of a continuous wet surface is prevented by the inner surface of the cups or bells, which remains comparatively dry.

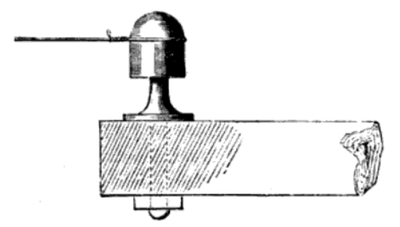

The first form of umbrella-shaped insulator was placed under the arm, but the present form is placed above it, for the reasons given in par. 344; and being now fixed upside-down, as compared with the original form, they are called iiwerfs. (Fig. 63.)

|

| Fig. 63. |

348. In choosing a material for insulators, it is necessary to consider the affinity of its surface for moisture—that is to say, its liability to become damp. Glass, although when dry a better insulator than porcelain, becomes damp much sooner. If a glass tumbler and a tea-cup, each filled with cold water, be brought into a damp warm room, the glass will be covered with dew long before the porcelain shows any signs of moisture. The glass supports of apparatus used for experiments on frictional electricity are varnished with shellac to lessen this affinity for moisture.

Cast glass has been very extensively used; but out of the hundreds of thousands of insulators which were erected, very few remain. It is probable that want of care in annealing may have been a principal cause of this failure; but even if duo attention in this respect would render cast glass more to be depended on, it is next to impossible practically to find out if the annealing is perfect or not, and glass at its best is but fragile and treacherous. It is, however, largely used in Switzerland and in the United States. Glass insulators break very rapidly in those deep railway cuttings into which the sun does not shine till late in the morning, so that, instead of being warmed gradually, they are heated suddenly at a time when the sun has attained great power.

349. It has often been observed of electrical machines that a cylinder has more power, and works better in a room, than a plate. Snow Harris considered that this arose from the nature of the surface of the glass, and found that a plate machine, constructed of several layers or thicknesses of window-glass cemented together, was as efficient as a cylinder, because both being made by blowing, have a fused surface formed without contact with a mould. Now the surface of cast or moulded glass is more or less affected by contact with the mould, and although this surface in the case of plate-glass is removed by grinding, the new polished surface is not as good, electrically, as one produced in contact with air alone.

Reasoning from this, Mr. Brooks, an American, introduced a blown-glass insulator in the form of a narrow-necked bottle. It certainly gives very good results as regards insulation, but whether because of its shape or surface is uncertain.

350. Ebonite would be the best of all materials for insulators were it not that after exposure to weather its surface becomes rough, so as to retain damp and dirt, and thus loses much of its insulating power. Compared with porcelain or earthenware, it less easily becomes wet in mist, but more easily in rain. Bain forms detached drops upon a surface of earthenware, but covers ebonite with a continuous film. Thus the latter acts with most advantage when it forms the inner cup of a double-shed insulator, and is protected by earthenware from the direct action of rain.

For special uses it is most excellent. An insulator may be made small and light, yet strong enough not to be broken without difficulty; and even after the surface has deteriorated, it will insulate well enough for a short line. The dark colour and unpretending appearance of a small ebonite insulator, protect it greatly from willful damage. It is found that in localities where the telegraph is exposed to mischief, a large white porcelain insulator is quickly broken; earthenware is less attacked, and a small ebonite insulator not at all. Mischievous boys cannot hit the small mark with stones, nor does it tempt them by its inviting appearance. Many who would not take the trouble to break an unpretending black cup, cannot resist the temptation of throwing at a large white one.

Hence a wire insulated with ebonite will be very free from the interruptions so frequently caused by broken insulators; this is a great advantage in remote places, and localities where willful damage is to be expected.

351. Brown stoneware is an excellent material, strong, cheap, and durable. Its surface is not equal to that of porcelain, so that it never insulates as well as the best specimens of the latter, but the glaze never cracks, as is sometimes the case with inferior porcelain.

352. The best material for an insulator is a really good porcelain, thoroughly vitrified, so as to insulate perfectly even when unglazed. Its value arises principally from its polished smooth surface, which resists the formation of a continuous film of moisture, does not retain dust, and is washed clean by rain. Very great attention has been paid to its manufacture, and it is now easy to obtain excellent ware.

353. Small pieces of ware are more easily burned, and therefore more likely to be perfect than large ones, double-shed insulators were, therefore, formerly of two cups, one placed inside the other, and joined with cement, but now they are made in one piece.

354. The several parts of an insulator are tested before they are cemented together, a small portion of glaze being ground off the top to test the soundness of the ware.

A trough lined with lead is fitted with racks to hold the insulators, which are arranged mouth upwards, and are then nearly filled with water. The trough is filled with acidulated water to within half an inch of the upper edge of the insulators. The edges are slightly smeared with grease, paraffin oil, or turpentine, to prevent damp spreading over them.

One pole of a battery of 250 Daniell cells is connected to the lead of the trough, the other pole to an insulated handle, a very delicate galvanometer being placed in circuit. The conducting wire is dipped into the water contained in each insulator in rapid succession, and if one is faulty the needle moves. The acid must be very carefully washed off after the tests. If a delicate reflecting galvanometer is used, the acid is unnecessary.

355. From its power of repelling water, grease greatly aids insulation; paraffin, again, enormously improves it; so that before testing samples it is necessary to ascertain carefully that they have not been coated with these substances to give them a fictitious value. New insulators were at one time dipped while dry and hot into melted paraffin, but it was found the surface so given deteriorated from retaining dirt.

356. In order to learn the comparative value of different kinds of insulators, they should be fixed upon standards exposed to the rain equally on all sides, and tested when the weather is uniformly wet. Almost any insulator will appear good in fine weather, while that which tests best in slight rain may not give the same result in extreme wet, when-the insulation is most tried.

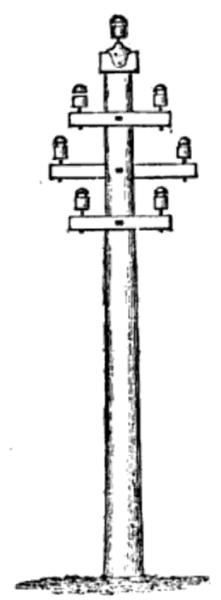

The best method of testing is to fix as large a number as convenient, certainly not less than ten of each kind, upon a pole, connecting them by a wire to represent the line-wire, and fixing a second independent wire to their bolts to represent the earth, and to determine the leakage from one wire to the other. To obtain good results the following precautions are necessary. Fix a pole not less than 20 feet high in an open place not sheltered in any way or on any side, place the arms on which the insulators are to be fixed at least two feet apart, the insulators themselves a foot apart. Do not place all of the same kind together, but alternate or mix them as much as possible, so as to obtain an average of exposure for all.

Take especial care that the wire representing the line touches each one closely all round and uniformly as to the number of turns: let it be all the same gauge. The object is to insure equal surfaces of metal in contact with the porcelain, because the leakage takes place from each point oi the wire over the surface of the insulator, and consequently if the wire does not touch uniformly, the leakage will vary with the variation of the surfaces in contact. If possible, divide each set of ten into two sets of five each. If these do not test alike there is probably a defective insulator among them which will vitiate the test, and must be removed. Never use separate insulated leads for each set to the testing-room, for these will become unequally damp on their surface and will vary in insulation, one from the other, more perhaps than the insulators themselves. Use only one leading wire, employing an assistant to shift it from one set to the other.

It is seldom that rain falls steadily and uniformly, so that if the testing occupies even five minutes there will often be considerable difference in the amount of moisture during the interval. To avoid error from this cause, after testing all the sets, commence again in the reverse order; if the two series agree, the observation is a good one. As the object of such tests is not so much to find the absolute resistance of the several specimens as to ascertain their relative value, it is better not to occupy time by testing in units, but rather to read a simple deflection, so that the tests may be made as rapidly as possible in order to ensure the greatest uniformity in the conditions; the absolute resistance can be calculated afterwards.

357. But with the greatest precaution these tests will often be very anomalous, and the only really satisfactory method is to place the insulators to be compared on wires running side by side for at least ten miles, and to test them every damp day for six months. It is obviously useless in any case to test in dry weather.

358. The following is the result of tests made in a situation quite free from insects, but somewhat smoky—Gloucester Road, Regent's Park, London—during twelve months, 1868-9:—It shows the proportional leakage of inverts, double cones, and shackles, all of porcelain.

Double shed inverts, mean leakage .26

Double cones, mean leakage .51

Shackles, mean leakage . 82

The effect of iron caps is seen in the following set of tests :—

Porcelain, without iron caps, mean leakage .38

The same, with open iron cages, mean leakage...44

The same, with closed iron caps, mean leakage. 55

Iron caps have another disadvantage; the water which drops from them covers the porcelain below with a coating of rust.

359. A long and narrow single-shed gives better insulation during wet than a wider double cell of the same length of inner surface, but it dries more slowly. Two parallel wires on a railway were insulated for about two miles, one with porcelain double-shed, the other with Brooks' glass. On a very foggy night the resistance of the Brooks was 290,000 ohms, of the porcelain, 150,000. But the following morning, just after the sun had broken out, the porcelain tested two million ohms, the glass only 390,000. The narrow opening in Brooks' retarded their drying.

360. Speaking generally, the best insulator is not that which tests best when quite new, but that which bears exposure the best, and therefore no tests are of value which have not extended over several months.

When the cups have narrow openings the insulation is very good at first, but their inside is apt to be filled with spiders- webs and the dirt which collects upon them, especially on roads lined with trees. A wider opening is less tempting to the spiders and less easily filled, so that although its insulation is not at first so good as in the former case, it falls off less rapidly. The aim in modeling an insulator is to find the best width of cell to satisfy all the conductors. Fig. 64 is the form used by the Post-office in 1884. It is drawn 1/3 of full size (364).

|

| Fig. 64 |

361. For a short line, a small, cheap, single cup insulator will be amply sufficient, and its maintenance need not be very carefully looked after. For a long line the best double cup insulators must be used; they must be kept clean, and carefully renewed when broken.

362. Various plans have been tried to prevent spiders building within insulators. Smearing with paraffin oil is effectual for a time, and it is found that they do not infest creosoted poles as long as the smell remains.

Periodical cleaning is the only effectual plan, and it is best to clean in the late autumn after the spiders have ceased to spin.

363. In smoky places also, periodical cleaning is very necessary ; and it is sometimes better to put up a new set and remove the old set to the stores for a more thorough cleaning than can be given on the line.

364. It is very difficult to remove the insulator from the arm without breaking, because the nut rusts tight to the bolt, and in consequence several attempts have been made to screw the bolt into the porcelain itself, so that it need not be removed from the arm. This has been at last successfully accomplished, and an experience of several years has shown its advantage.

A thread is formed on the head of the bolt, and a corresponding thread inside the insulator, which screws down to a shoulder on the bolt. A vulcanised washer is placed between the iron and porcelain above the shoulder, the elasticity of which enables the two pieces to be screwed tightly together, notwithstanding the necessarily loose fit of the screws.

365. When an insulator is made in two pieces, they are cemented together with a mixture of equal parts by weight of plaster-of-paris, portland-cement, and fine river or clean pit-sand (not sea-sand). These ingredients are mixed dry and sprinkled into sufficient water to form a cement; if the water is added to the powder instead of adding the powder to the water, the plaster is apt not to be properly saturated, and may afterwards, by absorbing more water, expand and split the porcelain.

866. The pins or bolts of insulators are cemented into them with a mixture of equal bulks of rosin, fine sand, and finely- sifted ashes from the smoke-box of a locomotive. Fresh rosin is added from time to time to replace that which is lost from continued heating. Sulphur splits the insulators.

367. The insulator bolts fit into holes in transverse arms or iron brackets fixed to the poles, and are securely fastened with nuts to prevent the insulators being lifted out by the wind. The bolts should be of such a length as to raise the insulator sufficiently above the arm to prevent its being blocked by snow accumulating under it.

368. At the top of the pole a galvanised iron roof is fixed, and over it a cast-iron saddle, into which the insulator bolt fits. The saddle must be fixed with screws, for nails split the Wood when driven at the end of a pole, and will not bear a strain. If the pole is creosoted, screws are also needed for brackets when the strain is great, as nails will draw out of creosoted wood.

369. When boucherised (coppered) timber is used, all nails, screws, and bolts must be galvanised. It is better also to dip them in tar before fixing them. The threads of all bolts should be greased to preserve them from rust.

The grooves or slots cut to hold the arms must always be well tarred, or painted, to prevent wet getting in and rotting the wood. This is very necessary, even in creosoted poles.

370. Wires are more apt to be blown into contact in the a vertical than in the horizontal direction; hence there is an advantage in using arms differing in length, placed alternately. This arrangement has the advantage, also, that if a wire break away from its support, it will generally fall clear of the one under it.

|

| Fig. 65 |

Fig. 65 shows the arrangement adopted in the postal telegraphs. The arms are alternately 24 and 33 inches long; and all the arms are placed on the same side of the pole, as this arrangement is more convenient for fixing the earth-wires.

371. It is better, as a rule, never to place more than two wires on an arm; because, when it carries more, it is difficult to see faults and to repair damages, and especially to lift poles when blown down or broken. Snow also will more easily adhere, so as Fig. 65. to cause a leakage from wire to wire. But the space is so limited that four wires are frequently placed on an arm.

372. To give greater distance between wires, they should, when fixed each on a separate support, as a bracket, be placed alternately, not opposite. The distance should increase with the span, and cannot be too great where there is sufficient room on the poles, for wires even 17 inches apart, and tightly strained, are sometimes blown together in storms.

Where 20 poles are used to the mile, the distance should be not less than about 12 inches vertically, and 16 inches horizontally, so as to clear the poles well. In England there is so little available room for poles that it is impracticable to give a much greater distance on main lines, but it should always be done where there are but few wires, for by so doing very many interruptions will be prevented.

373. Wires of different gauges are very much more apt to get into contact than wires of equal size, when set swinging by wind; for wires equal in weight and tightness, keep time one with another in their oscillations, but wires differing in weight and tension do not keep time, but move occasionally in opposite directions, and in consequence meet and hook themselves together.

It does not appear that wires blow into contact much more frequently in long spans than in short ones, provided they are uniform in weight, tension, and distance.

374. The top of the pole is the best position for an important circuit, because the wire is less liable to get into contact with others. The same circuit should always, as far as possible, occupy the same place on the poles, so that it may be readily identified.

375. The smaller the surface of wire in contact with the porcelain, the better is the insulation; so that if it were not for other considerations it would be best to allow the wire to run freely over or through the insulators, resting on a mere knife- edge. This was done in the earlier lines, the wire being threaded through a dice-box or double cone, and strained by a drum and ratchet at every half mile.

But the dice-box form does not insulate well enough for any but short lines, because it permits leakage to take place from the wire at both ends of the insulator. To remedy this fault, and still preserve the effect of the knife-edge, the wire was made to lie in a notch at the top of an invert. The insulation here was excellent, but it was found that the constant vibration of the wire, aided by the sand blown upon it from the soil, caused the wire to chafe.