[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 17, no. 9, p. 105-106, col. 1-2,1-3

First Three-Phase Plant in the Rocky

Mountain Region.

An important application of the three-phase system of long-distance transmission of power has recently been installed and put in operation at the Silver Lake mines, near Silverton, Colo., where power is transmitted a distance of three miles through some of the roughest country in Colorado. It is attracting considerable attention among mining men, as it is the first three-phase plant installed in the Rocky Mountain region.

The Silver Lake group of mines lies about four miles southeast of Silverton, at an altitude of 12,300 feet above sea level. They are owned by Edward G. Stoiber. The ore mined carries both gold and silver, is of a comparatively low grade and requires concentration.

| |||

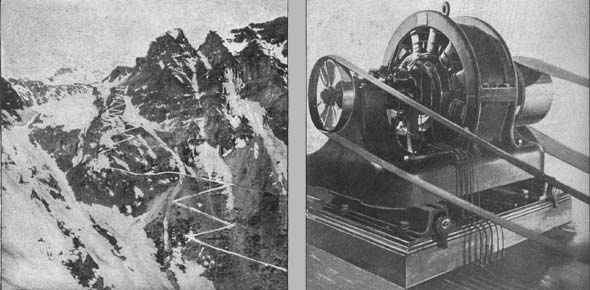

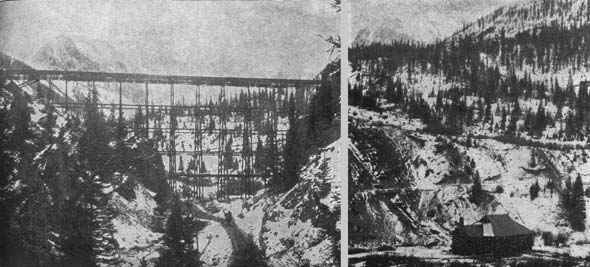

| Figs. 2 and 3. First Three-Phase Plant in the Rocky Mountain Region. |

Previous to the installation of the electric plant, the mill, which is situated on the shores of the lake, near the mouth of the mine tunnel, was run by steam. Coal was brought to the steam engine by the zig-zag path up the mountain shown in Fig. 1, and by the time it reached the furnace it cost $8.75 a ton. This represented a monthly expenditure of almost $1,000, and the expense proved a burden which went far to eat up the profits of the mine.

The plant is now operated by water power, which is brought from the Animas river, above Silverton, through a three by four foot flume 9,750 feet in length, which carries 2,350 cubic feet of water per minute. Flume and trestle are shown in Figs. 2 and 3. One of the great advantages of electrical utilization is here demonstrated, for it was found less expensive to build this costly two-mile flume, running from above Silverton down to a spot where the necessary head could be utilized, and then to transmit the current back to the mine, rather than to continue to burn coal at the price which it brought at the mouth of the Silver Lake mines. The head of water obtained is about 180 feet; this develops on the water-wheel shaft 640 horse power. The plant consists of two four foot double-nozzle Pelton water wheels, wheels with special buckets belt-connected to two 150 kilowatt General Electric three-phase generators. The current from these machines is given out at 2,500 volts and is transmitted over a distance of a little more than three miles to the Silver Lake mill and mine. The conductors are No. 3 B. & S. bare copper wires, one for each branch of the three-phase circuits. These are strung from the power house, shown in Fig. 3, up the mountain passes and through the rugged, forbidding country shown in the illustrations.

In one place where a chasm has to be spanned the wires leap from pole to pole a distance of 275 feet. They have been strung with special care as befitted the abnormal conditions. At each insulator the wire is run through a short piece of rubber tube as an extra precaution against leakage. Lightning arresters are placed at each end of the line and an additional safeguard against possible damage by lightning is provided in the shape of a barbed iron wire which extends the entire distance of the line along the tops of the poles and is grounded at every second pole. In this country where the storms are frequent and the lightning disastrous in its effects, every precaution is taken to frustrate possible dam-age from atmospheric discharges.

In the winter time the snow lies thickly on the ground and all intercourse between the mine and civilization is almost cut off. Some idea of the difficulties of the road may be gathered by referring to Fig. 1, where the zigzag route up the side of the mountain is shown.

Arriving at the mine the current is supplied to a 100 horse power three-phase induction motor run directly from the primary circuit. Another 100 horse power motor, as well as one of 75 horse power, is located beneath the ground, and current is supplied to these at a pressure of 220 volts, the reduction in pressure being effected by step-down transformers. In addition a 15 horse power motor runs a pump raising water from the lake to the mill, and one small one horse power motor operates a blower and the lights for a bunk, office and other buildings, both being connected to the secondaries.

The induction motor used is an excellent representation of the latest type of alternating current motor, built by the General Electric company, as will be seen by the cut, Fig. 4. There are no commutators, collector rings or brushes. The field winding is connected to the circuit, but there is no connection between the armature and any external source of current. The three-phase currents rising and falling in the field windings induce corresponding current in the armature winding and the armature revolves. The field armature cores are so completely laminated that all loss from eddy currents is practically eliminated. The speed of the motor is at all loads practically constant. The starting resistance for preventing any excessive current in the armature winding while gaining speed is contained in the armature itself, and the handle shown in the illustration serves to cut out the resistance when the motor is fully up to speed. These induction motors are built to stand the severest conditions met with in actual service.

The interest in this mine centers, of course, upon the economy induced by the electrical installation. The power used in the mill and the mines at the present time is more than three times as much as was used when generated by the steam engine previously employed. If, therefore, $1,000 a month or $12,000 per year would be economized by using the same power, an economy of not less than $36,000 a year is effected by the operation of the mine by electricity, and a greater power is available. Another advantage is that the operation of machinery inside the mine is made possible for the first time.

| |||

| Figs. 1 and 4. First Three-Phase Plant in the Rocky Mountain Region. |