[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 35, no. 19, p. 367, col. 2-3

Work of the Telluride Power Company.

In last week's issue of the Western Electrician (pp. 352 and 353) was presented Mr. P. N. Nunn's valuable paper on "Pioneer Work of the Telluride Power Company." This paper was read in Section D of the International Electrical Congress. The accompanying pictures were received too late to be used when the paper was printed, but they are so intrinsically interesting that they are presented, herewith.

| |||

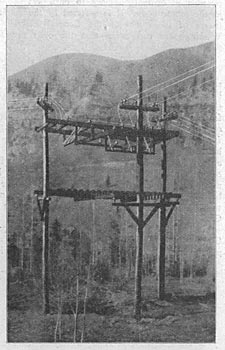

| Fig. 1. Work of the Telluride Power Company. — Open-Air Switching Junction. |

Fig. 1 is a view of one of the open-air switches that are placed at all junctions in the transmission lines other than generating or distributing points. These switches are mounted on standard line insulators and are operated from platforms similarly insulated.

| |||

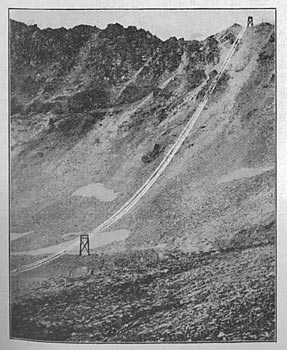

| Fig. 2. Work of the Telluride Power Company. — Long Span at Camp Bird Divide. |

An interesting picture is that in Fig. 2, which shows a long span at Camp Bird divide. There are a number of these long spans crossing canyons and divides near Savage Basin. The divides are bare ridges at an altitude of 13,000 feet and swept by frequent snowslides. They are inaccessible in winter and even in the summer the difficulty and danger encountered in constructing a transmission line in such localities may be readily imagined by studying the picture. Spans of this kind up to 1,100 feet are used, the longest being of No. I hard-drawn copper supported by half-inch plow-steel cable, both carried by the same insulators. The deflection is approximately 35 feet on a slope of 31 degrees. The strain insulators for the long spans are a series of the usual line insulators and pins upon a longitudinal arm. These arms are hinged to permit adjustment to span motion.

| |||

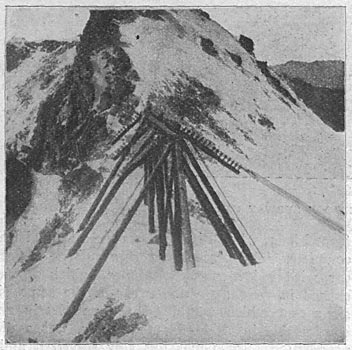

| Fig. 3. Work of the Telluride Power Company. — Supports and Strain Insulators at Camp Bird Divide. |

The stress upon the supports located upon the tops of the ridges and carrying the weight of these long spans is enormous, and very strong construction is necessary. Fig. 3 is a view of the tower on the summit of Camp Bird divide. The support, though simple and inexpensive, is exceedingly durable and has stood the test of years without repair. In this picture also may be seen the strain insulators referred to above.

| |||

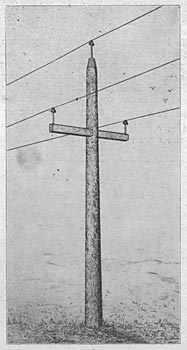

| Fig. 4. Work of the Telluride Power Company. — Sample of All-Wood Construction. |

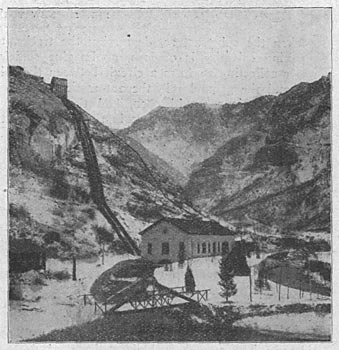

Fig. 5 is an exterior view of the power house, located at Logan, Utah. This plant was completed in 1901 and contains two 1,000-kilowatt revolving-field alternators direct connected at 400 revolutions to double-discharge turbines operating at a head of 212 feet. Duplicate lines over 100 miles in length connect this plant with the Provo (Utah) system. Distributing points are at Mercur, Eureka, Bingham, Salt Lake and Provo.

At present all-wood pole construction is used on the Logan lines. Fig. 4 is a good illustration of this type of pole. The three conductors of the line form an equilateral triangle 76 inches between wires, carried by a seven-foot cross-arm and the top of the pole. The cross-arms are mortised through the pole and wedged and pinned in place, thus doing away with all metal except conductors. This construction was original with Mr. A. L. Woodhouse. Extra long pins raise the insulators well above the cross-arms, and they are made of selected locust soaked from six to 12 hours in paraffin at 150° C. The cross-arms are of Oregon .fir, kiln-dried and soaked in boiling bitumen. During the four years' operation of the 400 miles of line thus constructed very few poles have burned down.

| |||

| Fig. 5. Work of the Telluride Power Company. — Logan Power House. |

Insulators of the Provo type have been used throughout, and of the many which have been broken the cause has generally been gun practice or stones. Leakage losses are inappreciable, except during the severest storms.