[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

col. 2-3

Electricity in Placer Mining at

Breckenridge, Colo.

BY JAMES E. JOHNSTON.

The development of the vast mineral resources of Colorado has been very materially aided in many instances by the utilization of the energy of her mountain streams, electricity being the main medium of application. The intermittent character of the flow of these streams, however, has been the most serious drawback to the extended use of waterpower in that section of the Rocky Mountains. Still, for some purposes, this is not as great an obstacle as might at first seem. This is especially so in the case of placer mining, which can only be prosecuted during the summer months, at which time even the most insignificant of these streams becomes a veritable torrent.

| |||

| Generating Station and Transformer House for Placer-Mining Plant at Breckenridge, Colo. |

The Goldpan Mining Company of Breckenridge, Colo., has the largest placer-mining plant in the state, if not in the United States. This plant, outside of the direct application of water under pressure to the washing of the gravel and elevating same from the pit, is largely operated by electricity.

Spruce Creek, some five miles above the present scene of operations, is the source of power. It is diverted from its natural channel and conveyed to the pressure box by means of a ditch some two miles long. From the pressure box to the generating station the water is conveyed in a steel pipe of varying diameter and thickness to suit requirements. The total effective head is 425 feet and the working pressure about 206 pounds.

| |||

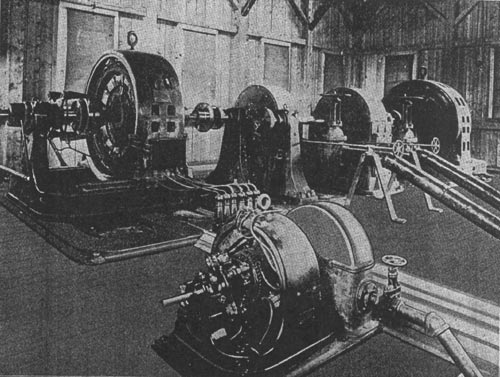

| Electricity in Placer Mining at Breckenridge, Colo. — Interior of Generating Station. |

The generating plant consists of two 200-kilowatt, alternating-current Westinghouse generators, delivering two-phase current at 440 volts, and direct-connected to two Pelton waterwheels.

The arrangement of these generators and wheels is novel and deserves mention. The wheels are set as closely together as possible to allow their extended shafts to pass each other. The shafts are thus parallel and of the same length and some four feet apart. On each end of each shaft is mounted a half of a flexible coupling of the leather-link type. At each end of this arrangement is placed a generator, which, by a tension screw and guides, can be placed so that its half coupling can engage with either shaft. Normally, one generator will be used on each wheel, but the plan allows either wheel to be operated with either generator and provides for emergencies that otherwise could not be met.

Two exciters, each of capacity sufficient to excite both generators are provided. They are direct-connected each to a suitable Pelton wheel. As a portion of the current generated is used in lighting the town of Breckenridge, and the remainder is applied to motor work of an intermittent nature, the switchboard is provided with two sets of bus bars, which allows of either multiple or separate running. This board is of blue Vermont marble, provided with a full line of measuring instruments of the long-scale type.

The raising transformers are located in a separate building, and are of the Westinghouse oil-cooled type. The line pressure is 10,000 volts, three-phase, it being the intention to cover ultimately greater transmission distances than those now used. The line is of No. 5 copper, two circuits of three wires each of one set of poles. Glass insulators are used.

The principal use in mining to which the power is applied is the driving of pumps, lighting the pit, etc. Two electrically driven portable cranes are used in moving larger boulders, etc. These cranes are of the boom type and are equipped with variable-speed, alternating-current type-F motors, capable of exerting 30 horsepower. One 150-horsepower constant-speed motor is used to drive a centrifugal pump and assists in keeping the pit dry. There is also a well-equipped machine shop, driven by a 50-horsepower, constant-speed motor. In this shop were made the large wrought-steel water mains used in the placer system.

Distribution of current is made to these motors at 220 or 440 volts, according to location from a sub-station at Breckenridge. The lighting of the town is from 2,200-volt mains, also from the same sub-station.

The plant has been in full operation for a short time only, but has proved the wisdom of the outlay by materially reducing the cost of the mining operation.