[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 34, no. 10, p. 195-196, col. 2-3,1-3

EUROPEAN PRACTICE IN THE CONSTRUCTION AND OPERATION OF HIGH-PRESSURE TRANSMISSION LINES AND INSULATORS.

BY GUIDO SEMENZA.

The first question which requires consideration when a line is to be built and the voltage of the current has been fixed, is, Which is the most advantageous wire section to be adopted? In a line you may allow any loss of energy, say, between two and 20 per cent., but what will be the most advantageous value, considering both the cost of construction and economy of operation? In some instances the line loss is limited by the regulation required at the end of the line: or in cases of small powers and high pressures. by the minimum section of the wire required to give the necessary mechanical strength: in other cases, the problem is generally purely one of economy. In the old practice, the most economical wire cross-section was determined without the aid of any calculation, in quite an empirical way, based on the consideration of gross expenses, weight of wire, etc. However, a close examination of the subject shows this to be an important factor of economy.

In Europe, generally speaking, important lines are carried across the country and not alongside roads; this is done for obvious reasons. The cross-country method allows the building of a straight line, thus avoiding angles to a considerable extent; then, again, the line is shorter. Of course, crossing cultivated land, as is generally the case in Europe, the cost of building the line is increased on account of the expropriations; but in the greatest number of cases, the extra cost of purchase of land or of right-of-way, is more than compensated by the shorter line. It must not be forgotten that the weight of copper increases in the ratio of the square of the length of the line, the loss remaining the same. It is often argued that following the high roads, the patroling of the line is much easier, but in many cases the right-of-way along the line across the fields is included in the purchase, and the system proves very efficient. At all events, well-constructed and straight lines far from the roads, do not show the necessity of very close patroling, although it is prudent to exercise it.

A most important question now arises. Whether metal poles are better than wooden poles? The principal reason for the adoption of wooden poles is the small cost of installation. For small lines this may be true. Another reason is the assumption that wooden poles increase the insulation of the line; and this also is true, but only when the insulators are very bad. A close investigation, however, will lessen the advantages claimed for wooden poles.

I shall now enumerate the principal advantages and disadvantages of iron roles. Advantages.—Wooden poles will last from two to 10 years, according to the nature of the ground. The durability of iron poles cannot be definitely stated as yet, but they will surely last go years, reducing the depreciation to a small amount.

Spans with iron poles may reach from 300 to 400 feet, and in exceptional cases, to 600 feet and more. This compensates for the higher cost of single supports. as, in lieu of three or four wooden poles one iron pole can be adopted, reducing the number of insulators, and consequently of weak points, and thus rendering possible the crossing of difficult passages.

The experience with existing lines constructed with iron poles, shows that the expense of keeping the line in proper repair and good working condition is very much reduced. With wooden poles the strain exerted by the wires will slightly displace the poles or rotate the cross-arms. Dry or wet weather will loosen the connections between cross-arms and poles and between pins and poles. In some cases wooden poles will twist in time.

All the above facts affect the insulators, pins and bindings, so that a certain amount of work is constantly required to keep them in good order. In line construction with iron poles, all these causes of deterioration are avoided and lines which have been in use from five to six years are in as perfect condition as they were when first constructed. The poles only require repairing every four or five years.

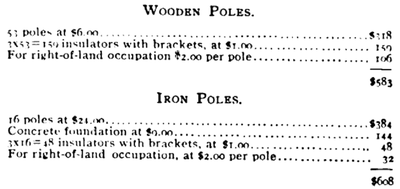

Disadvantages.—There is a somewhat greater capital investment. To illustrate this point, I submit the following figures, showing the difference between a line constructed with wooden poles and a line constructed with iron poles. based upon European prices and for a three-wire line for high-tension transmission:

|

Better insulators are required. As a matter of fact, the breaking of an insulator means a complete grounding: but, as we shall see, the insulators which can now be obtained reduce the frequency of this disturbance very much. On the other hand, it is not always true that wooden poles act as insulators, as for instance, in wet weather one cannot depend upon the surface insulation of wood. Therefore, from an economical point of view, iron poles require a larger capital investment; but the maintenance and depreciation are reduced to a minimum. These considerations tend to make the adoption of iron poles for important transmission lines more and more general.

Iron poles are calculated by the ordinary rules of mechanics. The forces acting on the poles are: The weight of the pole itself, the wind (both on poles and wires), and the strains transmitted by the wires. With equal spans on each side of the pole and no angles, the only forces acting on it are the weight of the wires and the wind. When spans are not equal there is a longitudinal strain which varies with the temperature. If an angle occurs, there is a component of the strain exerted by the wires which acts in a transverse direction. In the case of a vertical angle there will be a vertical component.

We must then begin with the calculation of the strains exerted by the wires. In doing so the effect of wind and snow must be taken into account, allowing a tension which does not exceed the limit of strain admitted for copper in coldest weather and with an overload of snow and ice. The maximum sag is also calculated in order to determine the height of the pole, as the wire must never come too near the ground: Taking into consideration all the above facts and effects, the poles are calculated in the same way as any iron structure.

Wooden cross-arms are sometimes employed with iron poles, in which case any system of pins may be used; but in general, supports constructed entirely of iron are preferable. In this case either iron or steel pins are used on brackets composed of angle iron.

A special cement is employed to fasten the insulators to these brackets, or, in the case of small lines, tarred rope is employed. This differs entirely with American practice, and no attempt is ever made here to use threaded insulators, as it is difficult to obtain good insulators with thread of the exact gauge. The best cement that can be employed for this purpose is composed of 10 parts of litharge and one of glycerine, well mixed.

When the span exceeds a certain length, care must be taken that the wires do not come in contact through their oscillation due to the wind. It is obvious that in order to avoid such a contingency, it is necessary that two or more wires should never be placed on the same level, and the adoption of cross-arms as practiced in America is not to be followed. In any case, it is easy to calculate the deflection of the wires from their vertical position, due to the force of the strongest wind prevailing in the country and midway of the span, thus finding the distance between the insulators to prevent the wires coming in contact,

One may ask if it is worthwhile to make such a careful calculation. That is easy to answer—in order to reach a high economy in the use of iron poles, it is necessary to put in them only the quantity of iron that is absolutely necessary; and this cannot be done without a close calculation of every element of the line. The author had the opportunity of calculating the poles of a line built without much precaution, and found that each pole weighed about 200 pounds more than was necessary. As the number of poles was 600, the extra weight represented a total of about to tons of metal in excess of what was actually necessary.

The problem of high-pressure insulation is very carefully studied by European electricians. It is well known that glass insulators are not used in Europe, and the reason for this, I believe, is that good porcelain can readily be obtained here. Glass is considered to have a better dielectric strength, but not as good surface insulation; moreover, glass is weaker against meteorological agencies, the superiority of porcelain being due to the materials composing the glazing. It must be said at once that European engineers do not consider American porcelain as good as European porcelain. It is possible that they may be mistaken, but a few tests made by the author on American insulators showed a higher dielectric resistance for the European porcelain, which in appearance, finish and homogeneity of material is much better. Perhaps the difference in these particulars may have had much to do with forming his opinion.

In designing an insulator the following points are to be considered: Dielectric resistance, resistance against surface arcing, mechanical strength, facility of cleaning, ease of construction. It is well known how the resistance against puncture can be increased, by making the insulators of several pieces, introduced one piece inside the other. In general, the different pieces are cemented together with a kind of glazing in the process of manufacture and put on the market as single pieces. The author does not follow this practice, but prefers having them furnished by the factory in separate pieces for the following reason: When the thickness of the porcelain reaches a certain limit the ordinary testing will not puncture a sound insulator. In testing an insulator made up of two or more pieces, one layer of porcelain may be cracked but is protected by the other layers. When the tests are performed on the single composing parts this cannot happen, and one is sure to have the insulators made up of sound parts. Moreover, each composing part can be better inspected and the character of glazing observed.

The ability of an insulator to resist surface arcing is due to its dimensions and shape, the latter to be considered under a double aspect: I. The protective action against moisture and rain. 2. The property of giving origin to electrostatic phenomena. An insulator with a very large petticoat on the top and only a second petticoat round the pin will not afford a very good protection against rain and moisture. as during a storm the inner petticoat will get quite wet. It is therefore good practice to have one or two intermediate petticoats, which will also insure the dryness of some part of the surface in all kinds of weather.

With reference to the influence of electrostatic phenomena on surface arcing it is only possible to venture some assumptions, although it appears that they have a certain basis of fact. It is well known to those who have studied tests on insulators that the surface arcing does not always occur at once, but seems to be preceded by a number of static discharges between the petticoats. These discharges, of a bluish color, are very marked with insulators having petticoats close together, in which arcing seems also to occur with large air spaces. It is not improbable that these blue discharges may produce an ionization of the air and moisture, which facilitates the striking of the arc.

DISCUSSION (IN ABSTRACT).

J. W. Lieb, Jr.: I would say that this paper is indicative of the character of analysis that European engineers give to mechanical problems when they are presented. It is, perhaps, true that the European engineer is not as active in undertaking pioneer work in new fields, particularly where large investment and commercial development are necessary, but I think it is also true that when these applications are once made by them that the constructions are subjected to very careful analytical treatment. I remember when one of the first electric railways was introduced in Italy, in the 90's, on the Sprague system, from Florence to the heights of Fiesole adjacent. In making a report on this construction an Italian engineer gave a most excellent analysis of some of the problems in connection with matters as applied to railway work, an analysis which has only been equaled in its thoroughness by some of the work that has been done in very recent years. It is unfortunate, I would say in this connection, that the work that is done by a good many of the Italian workers in the field of experimental physics and analytical investigation is apt to be lost to the world through insufficient publication. I think there are a number of cases where this has been the fact, notably the pioneer work that was done by Professor Pacinotti, which was buried for quite a few years before it was resurrected from the archives of a purely physical production. This was also the case with other investigators, but some of the more recent investigators, notably Marconi, have been more fortunate in having their work brought forward. Including the remarkable work of Professor Galileo Ferraris, there is a vast amount of careful research in physical work going on, done under most unfavorable circumstances, with limited means, and all through Italy will be found students who are laboring under the greatest difficulty in trying to construct primitive apparatus to conduct research work, and, as I said before, it is unfortunate that some of this work has not the advantage of being given that publicity which its value merits.

W. N. Smith: I think we must all regret the fact that the author of this paper is not here to tell us a little more about how the plant works. He has wound up his paper by saying that the results are satisfactory and the lines are economical and safe in operation. The methods which are so well outlined here are so radically different in structural details from nearly all the principal examples of first-class work in this country that it seems a pity we cannot get a little closer to these European fellows and have an opportunity to hear them tell just what happens or does not happen, as compared with the results we are accustomed to get from our work in this country. Their method of construction of the high-tension lines is quite different from ours as usually practiced. It would be interesting to know, for instance, how effective their methods of construction are, these vertical sets of wires one above the other, in the matter of preventing possible short-circuits; for instance, from small boys throwing wires over them. Perhaps small boys do not do those things in Europe; perhaps the police regulations are more effective, or the national government frowns on it to an extent that makes it impossible. That is a condition which does not obtain in this country, and a thorough threshing out of some of these different questions would be very useful to us as showing whether their methods are really better than ours or not. That is simply one of the things which occurs to me in looking over this paper, which I consider an unusually fine contribution to the cause of electric-power transmission. As I say, I cannot but regret that some of those gentlemen who are accustomed to build lines in this manner under European conditions are not a little nearer to us so that we could find out exactly how to compare the results of their work with the results of our own.

Mr. Lieb: I can perhaps answer one or two questions. I am sure Mr. Semenza regrets not being present at this discussion, and he emphasizes that in his letter to me. I remember when this trans-mission line was first spoken of and this transmission plant was first being considered. I was the chief engineer of the Italian Edison Company at that time, and one of the things that gave the gentlemen who were expecting to put their money into the concern a cause for apprehension was the liability of just such occurrences as the gentleman refers to, not so much from the small boy, because he is a difficulty practically absent from European work. One does not usually see a small boy around, and he is not generally engaged in making himself a nuisance, but to what extent the line might be subjected to disturbance by people shooting at insulators, and that kind of thing, which was feared. I am not able to say.

President Arnold: I can say there is just such a line as this almost completed, and perhaps in operation in Mexico and as you know, they shoot pretty freely in Mexico. The line is about 100 miles long, built with steel towers, regular windmill towers using seven poles to the mile, and supposed to be the most modern line now built. The gentleman who built it showed me photographs of it two weeks ago, and that indicates that at least one man in this country has awakened to the fact that Europeans know how to build transmission lines, and possibly we will learn considerable from the other side in that respect in the near future. I will say that the New York Central Railroad, with whose work I happen to have something to do, has considered this transmission question recently as to whether they would put the lines overhead or underground for the transmission of power for the operation of trains. They have come to the conclusion it is safer and more reliable in operation to have them overhead on steel poles than to put them in conduits. This decision is substantiated by the information we secured from the different transmission lines in this country. Every competent engineer whom we consulted said to go ahead and put them overhead if it is possible, because if there is any trouble you can get at it and repair it promptly, while if there is any trouble underground in conduits you cannot locate it and do not know what the damage is. There will be certain parts of the work which will be in conduits underground, but where we can go overhead we will do it. We will use steel poles of some such form as is outlined in this paper.

W. E. Dix: I would mention a recent example of a 40o-foot river span where they had some trouble with two or three of the triangularly arranged wires touching on account of severe winter conditions. They used phono-electric wire, stretched at high tension, in order to have the sag as little as possible so as to prevent any barns, etc., which should happen to go over the dam in case of flood, striking the span; but notwithstanding the precautions they had taken the wires were brought together. Now, had the arrangement suggested by this Italian engineer been followed I think perhaps it would have eliminated the trouble from that particular cause I would say further, in discussing the paper, that I think our American insulator manufacturers are now adopting the suggestions that have been brought out by the writer, namely, to reduce the number of petticoats, increasing the surface, and also increasing the space between the petticoats, thus reducing arcing and leaking from the shortened path.

C. F. Scott: It seems to me that there is a difference between the engineering inside the station and outside the station. The engineering inside the station, the development of electrical apparatus, has been in general in the hands of a few manufacturing companies, with a corps of expert engineers who have given their attention to these points, and they have developed the interior machinery, and this development has constantly increased until very high degrees of perfection have been reached. In general, it is thought that anybody can run a line outside of the station, and the engineering elements are left to the wiremen. The outside construction and system has been haphazard. It has been in the hands of this company and that company, and has been treated by local companies with little or no consideration. Some of these companies have done their work very well, but in the external construction the plant lacks the standardization, lacks the uniformity, and lacks the higher grade of considerations which have been given to other departments.