[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 20, no. 384, p. 245-249, col. 1-2

ELECTRIFYING ZION: — THE BIG COTTONWOOD POWER TRANSMISSION, SALT LAKE CITY, UTAH.

I

A KEEN and travelled observer, who puts the longitudinal limits of his wanderings at Turkey in the East and Utah in the West—from Moslem to Mormon—says a visit to Salt Lake City convinced him that from a sociological standpoint the followers of the Prophet Smith are more interesting as a study than the followers of the Prophet Mahomet. One needs to see the capital of the Church of Jesus Christ of Latter Day Saints, with its great ten-acre blocks, its broad, rectangular streets, its mountain water system, its quaint Mormon walls, temple and tabernacle, to appreciate the marvel of the Mormon exodus of 1848, and the stupendous works of the wondrous chief and builder, Brigham Young. The lever which became such a mighty power in the hands of this great natural leader of men is now discarded, but the work remains. Brigham Young practiced and advocated plural marriages because he wanted his colony to increase.

| |||

| R. M. Jones |

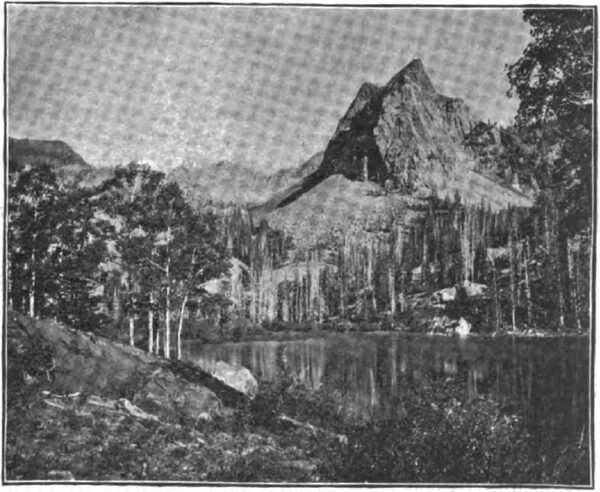

To him it meant fructification and rapid colonization. But polygamy is now dead in Utah, and the people have faced toward a new life. Confident in the strength of its honesty of purpose and its splendid half-century record of privation, patient industry, prosperity, culture and wealth, the great Mormon colony of the West is seeking touch with the rest of mankind, and expanding into wider sympathy with the outside world. Gentiles are now welcomed into the best Mormon social circles. The community on every hand shows signs of vigor and success, socially, politically, and financially. Since the abandonment of polygamy, the membership of the church has increased amazingly, and its missionaries in all corners of the globe tell of the rapid accession of converts that is being brought about by the removal of the primary cause of outside hostility. In the West alone, there are 400,000 communicants of the Church of the Latter Day Saints. The territory of Utah is to be raised to Statehood, and its material wealth is seen in the number and magnitude of its home industries. But its career is only just begun. It has within itself a fund of resources that will bring it into a leading place among the forces of the age, and it is to the development of these agencies that it is now bending itself. The sublime Wahsatch range, under the shadow of which Salt Lake City springs out of the plain, is studded thickly with water streams, caves, and pockets, fed by the springs and drainage of the mountain, the overflow from which has always been utilized by the Mormons for the fertilization of their valley farms. The grandeur and beauty of its peaks and lakes are unequalled even in the Bernese Alps, and the picture of Lake Blanche, with its setting of snow-mantled cliff, shown on this page, will suggest to the traveller in Central Europe the rugged and awful profile of the Matterhorn. This and seven other of the Wahsatch lakes, lying still, dark, and solemn, at altitudes of 11,000 to 13,000 feet, are now to be the means of filling the valley below with light and gladness. In the picturesque Big Cottonwood Canon, where the granite blocks for the ponderous and imposing Mormon temple were quarried, these waters are being dammed, and converted into a power that will develop the resources of Utah in mines, products, and manufactures, to an extent almost unparalleled in the history of the West. The Big Cottonwood Power Company has practically completed its plans for the generation and transmission of electric power from the various water supplies in the Big Cottonwood Canon, thirteen miles south-east of Salt Lake City, for the supply of light and power within the limits of the city, and to the factories and small towns in the vicinity.

| |||

| Lake Blanche: One of the Feeders of the Big Cottonwood Water Power. |

II.

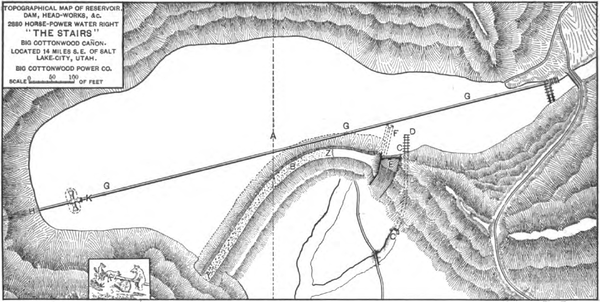

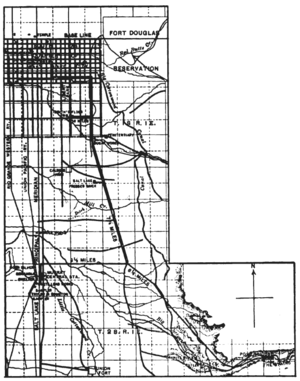

The power station is located in the Canon, at "The Stairs," 14 miles by pole line from the distributing station of the Salt Lake & Ogden Gas and Electric Light Company, in Salt Lake City. At this station, there is a minimum flow of 3,400 cubic feet of water per minute, which, working under 880 feet head, produces 2,447 H. P. any and every hour in the year. During nine months of each year, it will give nearly 4,000 H. P. The storage reservoir at the head of "The Stairs," has an available capacity of 24 hours' continuous flow of the stream, making all of the water available by using an excess during maximum loads and allowing the reservoir to accumulate during minimum loads. 58,800 H. P. hours per day of 24 hours, is looked for from this source, of which 68 per Dent. can be delivered in Salt Lake City in contract form, making 40,000 H. P. hours net daily. The 68 per cent. efficiency is derived from: Pelton water wheels 80 per cent., G. E. generators, 94 per Dent., G. E. transformers (raising) 97 1/2 per cent., line transmission 95 per cent., G. E. transformers (reducing) 97 1/2 per cent., or a total of 68 1/2 per cent. The map of the reservoir shows a pipe line extending from the head gates, submerged in the bottom of the reservoir, to a penstock or receiver wood housing with "grizzlies" located just below the bridge. This pipe, of steel-banded redwood, is anchored to the bottom by rock piles, and is to be used in the event of its being necessary to drain the reservoir, without interfering with the running of the station. This is accomplished by closing the head-gate valves, and opening the reservoir valves in the drainage tunnel, and the station will thus be supplied from the natural flow of the stream, during such time as the reservoir might be empty.

|

| Topographical Map of Reservoir, Dam, Head-Works, Etc., \"The Stairs,\" Big Cottonwood Power Co. |

III.

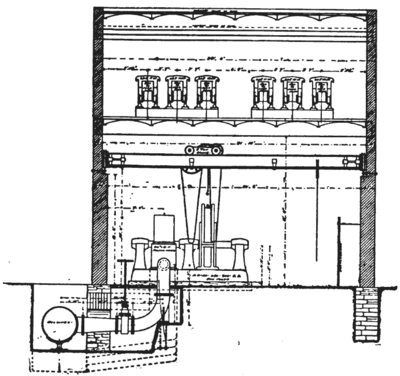

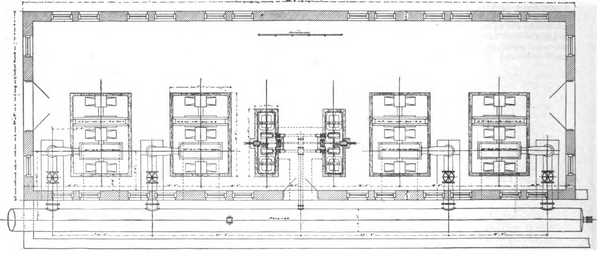

The outside dimensions of the generating station are 34 feet by 100 feet. The generating plant consists of four 450 K. W. three-phase General Electric generators, separately excited, non-compounded, set with armatures, parallel to each other, facing up in true line in the building as shown in plan and elevation on page 248. Each generator is driven by one heavy special Pelton wheel, 60 inches in diameter, provided with two nozzles 3 1/2 inch diameter. The straight nozzles are provided with a gate valve for shutting off, and the lower nozzle is equipped with a hood regulator, so that both good regulation and economical use of water are secured. Each nozzle at 370 feet effective head, produces 310 mechanical H. P., and runs at 300 revolutions per minute, its economical speed. The water wheel is keyed directly on the armature shaft, in lieu of a pulley. In addition to the generators named, four 12 1/2 K. W. exciters, made up in two sets, will be used; both generators of each set being connected together by friction couplings, and each generator to be driven by a 14-inch Pelton wheel, with cast housings. Each set will consist of two generators, and two wheels will be built up on a cast-iron base-plate, making a rigid and direct connection. This application provides exciting energy in two units, and at all times either one or two exciters are in reserve. The exciters are to be ran in multiple, and all connected to one common "bus line" on the switch-board. The three-phase generators will also be operated in parallel. There will be six raising transformers, 265 K. W. each.

IV.

The poles for the line construction were selected from live growth of Sand Point (Idaho) cedar. The smallest are 40 feet long, and 8 inches in diameter at the top. They are placed 100 feet apart. The line conductors consist of 12 wires, four circuits of three wires each; all No. 2, soft-drawn bare copper, and connected to the same common "bus line," at the generating and at the distributing station. The line loss, in delivering 1,520 kilowatts at 10,000 volts, will be something less than 5 per cent.

The transmission line from generating to distributing station is 14 miles by pole line. The distributing station is owned by the Salt Lake & Ogden Gas & Electric Light Company, who rent it to the Big Cottonwood Power Company at a nominal rent. It contains, for "step-down" transformation, nine 175 K. W. air blast transformers, from the secondary side of which the Electric Light Co. buys the current wholesale by meter. This arrangement is a most convenient one for both companies. The actual terms of the contract are that the electric light company is to be supplied with all the current it can dispose of for electric lighting and power, in units of 10 H. P., and under, the Big Cottonwood Company reserving the right to supply power to motors in units exceeding 10 H. P., and the right to reach such wholesale users of power by wires erected on the electric light company's poles, throughout all the districts within the city limits. The contract begins January 1, 1896, and runs for a term of five years. Its conditions are that the current is bought at 2,000 volts, three-phase, at a stipulated price per K. W. hour, which will be need to supply electric light and power for any purpose up to 10 H. P., and for elevator service up to any limit desired by the lessees. 2,000,000 units annually is the minimum limit of the consumption of current.

The present production of the electric light company is practically 3,000,000 units per annum by the use of coal after the usual central station methods, and the contract provides that as soon as the transmission power plant is in operation, the steam plant of the electric light company is to be abandoned, the price to customers reduced, and other changes made that will be to the advantage not only of both companies but also to that of the public, by promoting the production of cheap electric power.

V.

The final cost of the complete development is estimated at $300,000. An estimate of $300,000 for the original outlay for "The Stairs," would give for construction expenses—at 2,258 H. P. — $132.72 per net H. P. delivered in the city ready for use. The future of the company seems to be well assured. The company's affairs have been so well administered that much more than half the power to be developed has already been disposed of absolutely, and the guaranteed total revenue from completed contracts is over $100,000 annually. Although the company is confining its operations for the present to "The Stairs" supply, it has other valuable water rights partly developed by means of which it could at any time largely supplement its output.

|

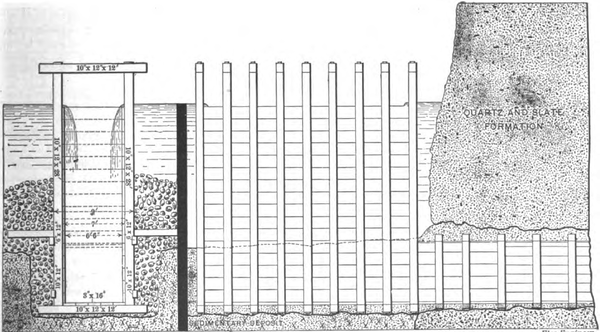

| Overflow Headgate and Tunnel Flume, at \"The Stairs,\" Big Cottonwood Power Co. |

VI.

It is worth while here to review briefly the natural advantages of Salt Lake City, which must be borne in mind if anything like an adequate idea of the importance and far-reaching effects of this great semi-Mormon enterprise is to be arrived at. Cheap electrical power will open up possibilities for electro-chemical work, such as the manufacture of aluminum. The district has bauxite in abundance, and in this industry power is all-important, and freight is hardly considered. For the manufacture of salt products, bleaching powder, disinfectants, soda, sodium, calcium carbide, &c., all the raw materials are on the ground, and cheap power only is needed. The electro-deposition of copper will certainly grow into a huge industry, for the extensive leads of copper ores are as yet undeveloped. A large copper smelting plant is now about ready to start. The electro-deposition of gold and silver is also a coming industry which will rapidly expand when cheap current increases the economy of the process. These are classes of work depending for their successful prosecution almost entirely on power, and requiring materials mined or found in the Salt Lake country in enormous abundance. In mills and factories the ordinary industrial operations likely to be created by cheap power are wool scouring, paper making, the manufacture of cotton fabrics and the making of flour. With the increase in these factories there will be a call for better facilities for iron workers and engineering work, which will require further power. There will be a prompt and large demand for current for electric transit. Cheap power will enable trolley lines to be pushed out all over the Salt Lake Valley, to be used for bringing farm produce into the city and ores to the smelters. With these improved facilities for transportation, the fanning industry of the Salt Lake Valley will increase enormously, and a large fruit trade will be established. Two electric roads are already operating successfully; the Salt Lake City Railroad, with about 70 miles of track, and 45 cars, and the Rapid Transit Company, with about 28 miles of road and 24 cars. These roads already stretch out from 5 to 10 miles from the centre of the city. The output of gold and silver ore with lead bases is infinitely larger than statistics show, owing to the fact that enormous quantities of ore are shipped to Colorado smelters. Before long these ores will be smelted in Utah by electrical processes. The headquarters of the large mines, such as the Ontario, Centennial Eureka, Mammoth, Anchor, Crescent, Silver King, and the various mines in Park City, Tieutic, Bingham and Mercur, are all located in Salt Lake City. The first successful practical application of the cyanide process for extracting gold ores was made at the Mercur mines, located within 10 miles of the city. There are four large smelters and five sampling works. These smelters and the mines require large quantities of power continuously through the year, and though the application of electricity to mining is somewhat slow, it will surely become general. The Ontario mine has taken the lead by putting in a small monocyclic light and power plant, utilizing the waters from the great drain tunnel.

|

| Power House of the Big Cottonwood Power Co. — Transverse Section. |

|

| Power House of the Big Cottonwood Power Co. — Plan. |

VII.

This is only a partial list of the commercial possibilities which will be opened up by the new conditions. But the Big Cottonwood transmission is remarkable not only for the immense development of which it will be the incentive, but as affording at its distributing station, an instructive illustration of supreme ingenuity in grafting new methods on to old appliances, and in combining the best points of more or less antiquated, and of modern practice in a harmonious and highly effective system of electrical distribution. It is fortunate that this critical work has fallen into such hands as those of R. F. Hayward, the able general manager of the Salt Lake & Ogden Gas & Electric Light Company, whose deservedly high reputation as an electrical engineer extends far beyond the limits of the State in which he has so successfully labored and into foreign countries.

The new system, when complete, will consist of a network of primary mains with a network of low tension secondaries, wherever the houses are in close proximity to each other. The primary mains will be at 2,000 volts. They will run along every street east and west and will have equalizing cross mains on several streets running north and south. There will eventually be ten feeding points, though at first only six will be required. The secondary mains will be used almost entirely; only when, the houses are very scattered will separate house transformers be used. In the commercial district, the secondary and primary, mains will eventually be put underground, though this is not immediately contemplated. The transformers will be placed at street intersections in banks either fixed on the poles or in any suitable location near the intersection. In the commercial districts there will be a bank of transformers at every street intersection; but in the incidental districts one bank will be placed at every other intersection, the blocks being 792 feet square. Arrangements will be made for switching out alternate banks of transformers during light loads to save the waste of energy. To do this both the primaries and secondaries of the transformers will have to be controlled. The feeders will be brought from a distributing station situated near the centre of the town. The current will be supplied from the generators of the Big Cottonwood Power Company's station on the three-phase system. The feeders and primary mains will therefore consist of three wires each of the same size. The secondary mains will consist of three wires and a neutral wire. The voltage between any one of the three wires and the neutral will be 115, and this will be the voltage of the lamps. Motors, synchronous or non-synchronous, can be connected at any point to the secondary mains, or, when the motor is large, separate transformers will be need. It is intended to eventually use the alternating current for all arc lamps, in which case they will be connected to the secondary mains with small transformers. For street lighting it will be necessary to make special arrangements for switching the lamps on and off. At present there is a mixture of all kinds of systems in the station, but when the new system is complete, instead of the multitude of heterogeneous wires and circuits now existing, there will be three 2,000 volt primary wires and four secondaries on each street running east and west, and only four secondaries on streets running north and south.

|

| Map Showing Location of Power Line. |

The distributing station will be a substantial fireproof building, with a room for the 10,000 volt step-down transformers, a room for the 2,000 volt switchboard, and a room fitted up with instruments for testing and calibrating meters, etc. The current will be brought from the step down transformer to the distributing board. On the first panel will be a three-phase Thomson wattmeter for recording the energy received; also three amperemeters, one in each leg of the system, to show the balance; also, a station voltmeter to show the volts on the secondary wires at the feeder points, for which purpose, pilot wires will be put up. From the ammeter the current will pass along three bus bars to the several three pole switches, from whence it will pass through fuses to the feeders. The feeder switches are designed for 100 K. W. each. Only ten feeders will be at first arranged for, though more will be added as they are required.

The distributing system and feeders have been designed of ample capacity for a very small drop, and with the complete system of primary and secondary mains the regulation will be very perfect. By cutting out transformers during times of light load, it is expected to obtain a very high distribution efficiency.

The change from the old to the new system will be no easy matter, and will have to be done gradually. In order to take the initial steps immediately three 150 kilowatt three-phase alternators (General Electric) will be driven by the existing steam engines, and will supply energy in the commercial district until the Cottonwood plant is ready. When the Cottonwood supply is established, these generators will be used as synchronous motors to drive the are lighting machinery, and when the direct current arc lamps are replaced by alternate current lamps the machines will be available for use as motors whenever required. It is contemplated to use presently the old single-phase alternators as motors. In this way much of the old plant can still be utilized.

VIII.

The Big Cottonwood is thus to take its place among the great power transmissions of the country. With it will always be inseparably connected the name of Robert M. Jones, who planned the scheme and piloted it to success with characteristic skill and tenacity. Mr. Jones is a distinct figure in the history of electrical work in the West. He was born in Ashtabula Co., Ohio, in 1853. In 1870 he joined a camp engaged in government surveys in Indian territory. After two years he obtained the position of U. S. Deputy Surveyor, and in that capacity was closely identified with civil and mining engineering through New Mexico, Arizona, Colorado, Wyoming and Utah, until 1884, as he describes it: "A dismal siege of fourteen years; most of the time in advance of civilization, soap and railroads." During this period at intervals he had the supervision and handling of mining and milling machinery, and held the post of Master Mechanic of the Quartermaster's Department, of the District of New Mexico and Arizona for two winters. In 1880 he brought out a "solar transit," combining the meridian-giving qualities of the Bart solar compass, with the accuracy of the engineer's transit. Up to 1885 the electrical industry in the Intermountain region was confined to telegraph and limited telephone work. In electric lighting there were only three small Brush stations, at Denver, Cheyenne and Salt Lake City, respectively. Mr. Jones took a prominent part in the organization of the Laramie (Wyoming) Electric Light Company, conducting the business as secretary and manager, and planning and superintending the mechanical construction of the station, which was equipped with Edison apparatus. At this time the Laramie station was rated the seventh as to capacity in the United States, and for three years of Mr. Jones's management it was the second as to dividends. Mr. Jones was the first to recognize the value of the Sprague direct current motor for Western work, and he installed three of the first motors made — 25 H. P.—for driving a too barrel capacity flour mill in Laramie. The installation worked without a hitch. It was at the time noted in the East as a matter for surprise that the very earliest applications of electrical transmission of power could be made in such an out-of-the-way country as Wyoming. In May, 1889, Mr. Jones began the construction, under private contract, of the electrical equipment of the Salt Lake City Railway with Sprague apparatus, and he has since been associated with practically all the important electrical installations in Utah and Wyoming. In point of fact, he holds a record of over 90 per cent. of the entire electrical work done in those territories. Since 1886 Mr. Jones has been actively engaged in the engineering development of the Big Cottonwood transmission which is now regarded as the third installation in the country in point of the power developed and the importance of its commercial bearing.