[Trade Journal]

Publication: Brick

Chicago, IL, United States

vol. 24, no. 1, p. 64-66, col. 1-2

The Manufacture of High Potential Porcelain Insulators.

The manufacture of high potential or high voltage insulators in porcelain is a subject that has not been touched upon in these columns to any very great extent although it is a very interesting one. Glass insulators for outside use were used almost exclusively for a long period until the porcelain insulators came out a number of years ago. The process, although interesting, is simple and runs along the same line as the manufacture of pottery or any other glazed clay goods. A description of the mode of operation may not come amiss at this time, and for convenience sake we describe the plant of the New Lexington High Voltage Porcelain Co., of New Lexington, O.

To start with, the plant is located very conveniently along the tracks of the Cincinnati and Muskingum Valley railroad, being a portion of the big Pennsylvania system, also having a side track in from the above corporation. The clay as it comes from the cars is shoveled direct from the cars into the clay-bins. a separate bin being used for each kind of material, which includes, as a general rule, china clay or kaolin, ball clay, flint and spar. The company uses as a general rule a Georgia kaolin, while the ball clay comes from Tennessee; the flint is Pennsylvania flint, and the spar comes originally from Canada, but is brought to this country and ground in pebble cylinders before it arrives at factory. The flint is treated in the same manner before it arrives at the porcelain plant. When these clays arrive at the plant they are carefully tested to see that no materials are of inferior quality or contain impurities that would he injurious to the ware when finished.

| |||

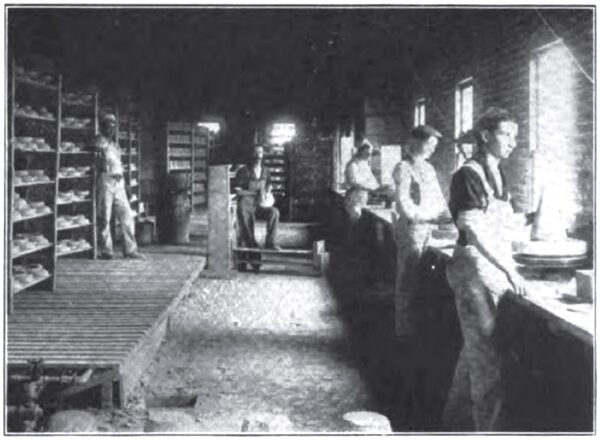

| Making and Finishing Insulators. |

A small track runs along inside the factory close to the clay-bins so that the raw materials may be shoveled onto a car which will hold a charge of from 1500 to 2500 lb. These trucks are arranged with a secret scale, so that the materials may be correctly proportioned. After the clay is taken from the bin and weighed, it is taken to the blunger mill, which in this plant is different from that of any other pottery from the fact that in place of using a regular blunger mill a grinding cylinder is used. This machine is a huge cylinder, six feet in diameter and about five feet in length. It is lined with porcelain blocks, which are about two or three inches in thickness and which the company made at this factory. This cylinder contains about a ton of imported flint pebbles such as are picked up off the beaches of France, and sometimes from Iceland, although the French pebbles are coming into use more generally. After the clay has been carefully weighed, the door of this machine is opened and the clay and other ingredients are placed within the mill where the mixing is done by the pebbles after the machine is set in motion. The reason given for the use of this design of machine is that it more thoroughly mixes the body and grinds it finer at the same time. A trouble that is experienced by the average potter is the fact that as a general rule, the ball clay, which is very plastic and tough and sometimes very hard also, is almost impossible to dissolve and to mix with the other materials and as a consequence when the mixture is emptied from the mill it leaves the ball clay behind. Not so in this case as the pebbles more thoroughly blend the materials and grind the ball clay up so that a more thorough mix comes from the machine than would be the case if the blunger mill were used.

When the clay has been thoroughly mixed it is allowed to pass from the pebble mill onto a screen covered with a fine brass lawn where the coarser particles are removed from it and the materials then pass into a cistern below in which an agitator is located and where the materials are kept agitated and not allowed to settle before they are pumped from it into the filter press, which is the Patterson make and is of 72-chamber capacity. When the clay has been pumped into the filter press and the superfluous water removed, it is taken from it in the constituency of putty and is then conveyed to the body pugmill, which is very similar to the average brick works pugmill except that it is vertical. The clay is generally run through this machine twice to remove the air from it and to get into a workable condition. It is then put onto a clay elevator, which is nothing more than a belt running in a slanting position from the first floor to the second and on which wooden steps are bolted to hold the clay. After the clay has arrived on the second floor it is made into ware on jiggers in plaster molds. The wares are then placed in the dry rooms to dry until they come easily from the plaster molds and are then removed, the plaster mold being brought into service again immediately. The wares are then smoothed up or “finished,” after which they are removed to the dipping room, where they are dipped in the glaze which is, as a general rule, an Albany slip. This glaze is composed of different ingredients, the kind of glaze of course governing this mixture. This material, like the clay body itself, is first weighed carefully in its dry state and is then placed in what is called the pebble glaze cylinder, which is about three feet in diameter and about four feet in length. This cylinder, like the large cylinder, is lined with porcelain blocks and flint pebbles do the grinding. The material is, of course, saturated with water after being placed in the cylinder. After the ware is glazed it is taken to the kilns, three in number, where it is burned. This ware is all burned in saggers, which are clay receptacles, in shape somewhat resembling an oval box without a lid, and the walls of which are about one inch in thickness, although this may be somewhat less. These saggers resemble in color and general make-up an ordinary fire brick. They are made of what is called a sagger clay, which is not unlike the ball clay in appearance, although it is a less expensive clay, being as a general rule a native material.

| |||

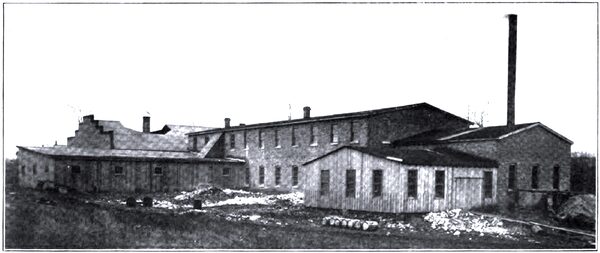

| The New Lexington High Voltage Porcelain Co's. Plant at New Lexington, O. |

The saggers that have been broken are taken to a 5-ft. grog pan, which is nothing more than a dry pan such as is used in any brick works except that it is about half the size and in which these broken saggers, called “sagger shorts." are ground to almost a dust called “grog.” This is mixed with the sagger clay and allowed to soak in boxes and is then run through a pugmill when it is ready for use. In most potteries and other clay-working establishments in this country, these are made by hand over wooden drums or molds, but at this factory they are made on a huge jigger in the same manner that the ware itself is made. These saggers are dried on what is called a sagger flue, which is nothing more than a long flue conveying the heat and which rests upon the floor in a horizontal position, being built of brick, and on which the saggers are placed and dry very quickly. These are generally loaded lightly for the first time as they are still in their green state when placed in the kiln, but after the first firing, they are hard and may be used over and over again.

| |||

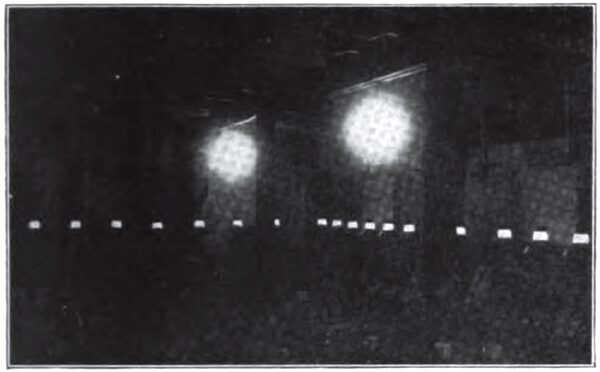

| Testing Insulators by Night. |

When the insulators are removed from the kilns they are taken to the testing rooms where they are tested by electricity to the voltage at which they are to be used. The company of course employs a regular testing man but a great many of the larger buyers of these goods prefer to test them themselves and often send a man to the factory who tests the insulators and then stamps them with his signature when found good. The plant is equipped with a regular testing outfit connected with a dynamo in the engine room and run from the main engine.

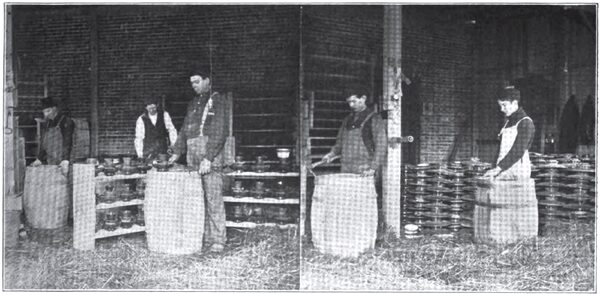

After being tested, the insulators are ready for shipment and are taken to the packing room from the ware room, where they are packed in straw in car load lots generally, but when not shipped in that quantity are packed in wooden crates in straw.

| |||

| The Packing and Shipping Departments. |

The plant has a capacity of 6 kilns, three of recent construction. The buildings are all of brick, the kiln rooms having sheet steel roofs. The company is also installing an additional equipment of machinery the same as the first installed and of the same capacity which, together with the additional kilns’ capacity and additional buildings, will more than double its capacity.

The New Lexington High Voltage Porcelain Co. was organized about three or four years ago by A. S. Watts, who became its superintendent and remained in that capacity until about a year ago when Mr. Watts removed to Victor. N. Y., taking charge of the factory of the Locke Insulator Mfg. Co. there. Mr. Lowry of Roseville, O., became general manager and in which capacity he remains today. The plant has been successful and Mr. Lowry, being a practical man and a good business man also, seems to keep the plant working to its utmost capacity. Its goods are in demand and the company has the reputation of putting out as good insulators as can be made.