[Trade Journal]

Publication: Brick

Chicago, IL, United States

vol. 27, no. 5, p. 177-179, col. 1-2

The New Lexington High Voltage Porcelain Co., New Lexington, O.

An industry that has grown to be quite a power in this country and one that has not been given very much attention in the clayworking field, due, no doubt, to the secrecy in the manufacture of this class of goods, is the porcelain insulator business. Insulators of all kinds are now made of porcelain, from the small insulator or knob to insulators required to stand a test of over 150,000 volts. These are all made of porcelain and the insulators of the latter type are all of larger size and are made with caps to protect them from the weather and to prevent the insulator from taking up the current. At the factory of the above-named company, nothing is made but what is known as high-voltage stuff, none of the smaller varieties, such as knobs, cleats, rosettes, sockets, tubes, etc., are made there as they devote their attention strictly to the larger class of goods.

| |||

| Jiggering Insulators. |

The process of manufacture is a great deal the same as the manufacture of pottery ware, although not so intricate as a whiteware pottery where the goods are decorated.

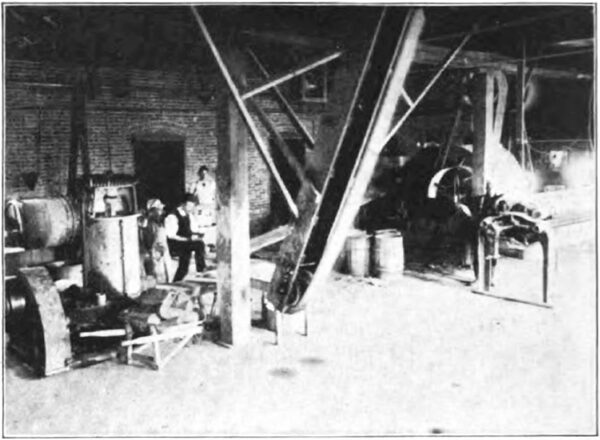

The slip-room or mixing-room where the clay is prepared, is almost identically the same as any ordinary pottery. The clay, flint, spar, etc., are thrown from the cars they come in, into the clay bins which are located just outside of the slip-house. The different clays are then carefully weighed up and wheeled to the blunger mill, which in this case is a large revolving cylinder and not the regular pattern blunger mill. A peculiar thing about the high-voltage-porcelain industry is that they invariably use cylinders to mix their body in and not a regular blunger mill. They claim that a porcelain body may be easier and more thoroughly blunged in a cylinder than it can in a blunger mill, and it certainly is plausible. A hopper is placed over the door of this mill and the clays are then thrown; the mill is run for a certain length of time until the charge is thoroughly blended and the tight door of the machine is then removed and a door With a nozzle on is then placed on in its place. The charge from the blunger, which by the way has been saturated with water in the Munger mill, is then allowed to run into the agitator where it is kept agitated or stirred up. It is not allowed to settle until the workmen are ready to pump it into the filter presses, which is done by means of pressure pumps, forcing the liquid clay from the agitator into the filter presses, from which it comes in the constituency of putty. A peculiar thing about the porcelain business is the fact that a steam pump cannot be operated successfully for pumping clay into a filter press, due, no doubt, to the fact that the body contains so much grit that it cuts the plunger and packing to such an extent that it does not pay to use them.

| |||

| The Testing of the Insulators. |

After the clay comes from the filter presses, sometimes it is stored in a damp clay cellar for as long as two, three, or even four weeks, where they have the necessary room, the longer the better, and is then removed and run through the pugmill. In some factories the clay is not aged at all but is run through the pugmill as soon as received from the filter presses. However, it is best to age the clay somewhat, as aged clay works much easier and makes smoother and much evener ware and it also reduces cracking and breakage at the kilns. The clay is run through the pugmill, which chews it up and removes the air from the mass. A little water is also run into the mill at the same time, tempering the clay to any desired constituency. The porcelain clay, being so tough, is very hard to pug and as they use their clay so hard it also makes this work very tedious to get the clay tempered rightly. Sometimes it is necessary to run the clay through two or three times before this is accomplished. This, of course, depends a great deal upon the kind of pugmill used; in the one shown in the illustration, the clay is run through once and, at times, twice.

| |||

| The Mixing Room. |

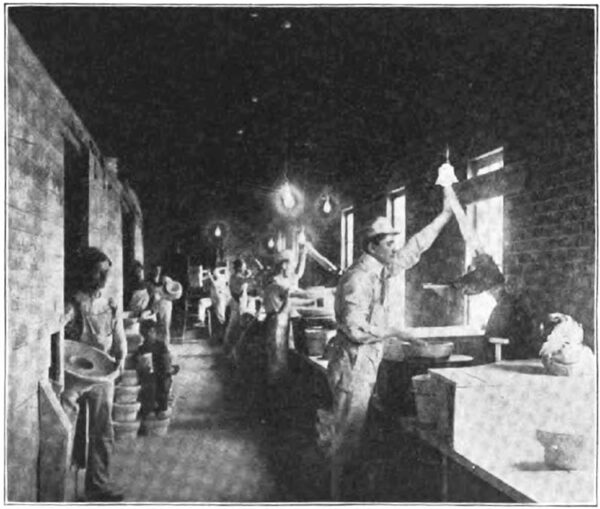

When the clay is received from the pugmill, it is cut into lengths of about 2 ft. with cutting wire, and placed on a clay elevator, which is an endless belt running over two pulleys, one on the first floor and one on the second floor. These are run by a set of tight and loose pulleys, in order that the elevator may be thrown out of gear at any moment. On this belt are placed, at intervals, wooden steps or shelves and the clay is set upon these shelves, the belt being placed on a slant in order to hold the clay on more securely, and by this means it is elevated to the second floor. When the clay reaches the second floor it is then delivered to the workmen, mostly jiggermen. All the insulators of this type are made upon a jolly or jigger, the different parts being made in this manner and stuck up or stuck together afterward.

After the ware comes from the jiggerman it is placed in the dry room where it is allowed to dry until by shrinkage the ware is ready to be removed from the molds. The boys called mold-runners, as they take a freshly-made piece into the dry room, bring back a dried piece which is removed from the mold, which is then handed to the jigger-man who uses it again. In this manner an endless chain is formed. The ware from the mold is placed upon a working-board which holds several pieces and is carried to the finishers. The finishers turn the pieces, removing the rough edges, and carefully finish and sponge each piece. The ware is then ready for glazing.

| |||

| Interior of Kiln Room. |

Different kinds of glaze are used for this purpose, but Albany slip is used more extensively than anything else.

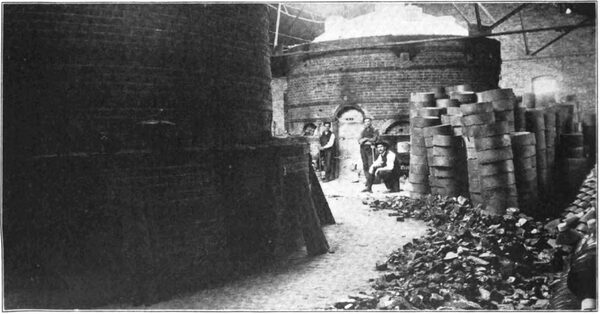

The glaze is then allowed to dry, although not much drying is necessary as the dry clay absorbs all of the moisture immediately, and is then taken to the kiln sheds where it is placed in saggers in the same manner that ware is placed except that no sand can be used as it would interfere with the glaze. No stilts or pins are used either.

In most of the high-voltage-porcelain factories with the exception of East Liverpool, O., coal is used for firing. At East Liverpool, and one or two other points, gas is used exclusively.

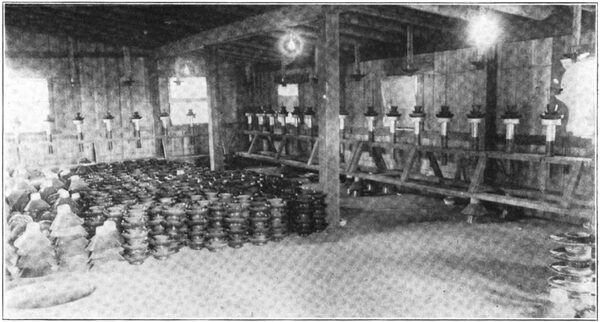

These kilns are, for the most part, down-draft. The ones in the plant we are describing are of this pattern and are about 25 ft. inside diameter. After the insulators have been fired, they are removed from the saggers and carried to a testing-room where they are all tested by electricity, to the necessary number of volts, depending, of course, upon the size of the insulator, style, use it is to be put to, etc. This part of the work is very interesting as every insulator that does not stand the proper test is thrown away and not allowed to leave the factory.

These insulators are then packed with straw and are shipped in barrels, crates, boxes. etc., except where cars are loaded in the bulk, in which case, the insulators are loaded directly into the cars, straw being used to pack them in. As a general rule, the factory making the insulators sells the wood cross arms, braces, wood pins, etc., which are sometimes shipped right along with the insulators.

The above factory has been in operation something over two years and has had a very good trade.

The plant has a capacity of two kilns and the whole factory is well constructed upon modern lines, is all brick and is one of, the best porcelain factories in the country. The equipment is all modern and thoroughly up-to-date in every detail. The power is supplied by a powerful boiler and engine of sufficient power to operate everything in the plant and then have a surplus. The mechanical equipment, conŽsisting of clay-preparing and manufacturing machinery, finishing machines, etc., was supplied by the Patterson Foundry & Machine Co., East Liverpool, O.

There are several factories in the United States manufacturing the same class of goods. Of these two are located at East Liverpool, the R. Thomas & Sons Co. and the Electric Porcelain Co. There is also one at Victor, N. Y., the Locke Insulator Co., one at Lima. N. Y., the Lima Insulator Co., and one at Peru, the Peru Electrical Mfg. Co. All of these companies are turning out more or less of this class of goods and all have the reputation of manufacturing an excellent product. The Electric Porcelain Co., the R. Thomas & Sons Co., and the Peru Electrical Mfg. Co. also make all other kinds of porcelain, including tubes. etc. The Peru people fit up their porcelain complete with the brass parts also and use a great deal of their own porcelain of the smaller varieties. The Locke and Lima people make nothing but the high-potential material and the Lima company is practically a new concern, only having been making goods for the past few months. For the most part this company is composed of people formerly connected with the Locke Insulator Co.