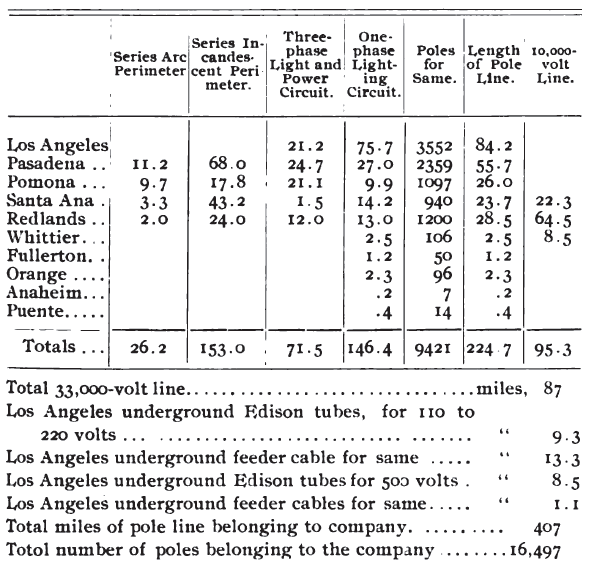

[Trade Journal]

Publication: The Journal of Electricity, Power and Gas

San Francisco, CA, United States

vol. XIII, no. 1, p. 9-24; 24-38; 42-46, col. 1-2

The Generating, Transmission and Distribution Systems of

The Edison Electric Company of Los Angeles, Cal.

By Geo. P. Low

[Of all the world, America is infinitely far in the lead in the practical applications of transmission engineering, and of all America, California shows greater development along this line than any other State and the Union, yet to nowhere in California is there to be found more interesting long distance high voltage work of almost every conceivable description than exists in the southern portion of the State, where in a single system of The Edison Electric Company, of Los Angeles, alone may be marked not only the first polyphase transmission station ever built for commercial service in America, but where also may be traced, step-by-step, every advance made in the art of electric power transmission down to the present time. And the first among the prominent transmissions of southern California is this selfsame The Edison Electric Company, they principle hydraulic, mechanical and electrical features of which it is the purpose of this article to describe.

| |||

| The Santa Ana Plant From A Carbon Print |

Side-by-side the oldest American built polyphase apparatus works in perfect accord with the newest; fears forebodings, once all but overpowering, have gone the way of hobgoblins of childhood, and the first power transmission-born project of scarcely more then a decade ago, has grown and grown and grown from a slender infancy to the very perfection of corporate maturity, so that now, when it has but to ask for millions for extensions to receive them, it seems but fiction to think of a time but twelve short years ago when it proved to be all but impossible to secure the paltry sums represented in the cost of the plant that is the nucleus of the present mighty enterprise. If American prosperity has increased of late, the transmission development has advanced by a yet more rapid stride, and here and southern California the engineer may see it all, from its earliest stages to it's acme of perfection, and in seeing it he will be struck not only by its historical significance, but also by the unprecedented thoroughness of its hydraulic development and the marked originality, in equal thoroughness, which characterizes its every electrical feature. The Editor]

The system of The Edison Electric Company is a composite one, constituting, as it does, eight separate and distinct corporations, which, in process of time, have been gradually merged into the single concern of great magnitude, which bears the name of this article. If viewed from the standpoint of its interests in the city of Los Angeles the company originated in the comparatively small concern eventually known as the West Side Lighting Company, which, as time wore on and business increased, developed into the Edison Electric Company, that, in turn, became of great importance, especially after its absorption of the Southern California Power Company. Comparatively short periods of time wrought marked developments thereafter, and rapidly following the absorption of the Southern California Power Company by the Edison Electric Company came the acquisition in the sequence named of the Pasadena Electric Light and Power Company, the Santa Ana Gas and Electric Company, the Redlands Electric Light and Power Company, the California Power Company and the Mountain Power Company, all of which have been, within the last few months, as stated, merged into The Edison Electric Company.

THE REDLANDS BEGINNING.

And from a transmission standpoint, as stated, interest centers first about the plant of the Redlands Electric Light and Power Company, and then about the then-extraordinarily high voltage long distance lines of the southern California Power Company. It was in January, 1892, transmission development had begun to reach such a stage of progress as to inspire confidence in its ultimate commercial feasibility, and at the same time local conditions in and around Redlands were such as to make the proposition of transmitting the energy of the water power of Mill Creek to Redlands and extremely favorable one. It is certain, at events, that in the month named Messrs. George H. Crafts, George B. Ellis, F. G Ferand and H. H. Sinclair began to discuss the project with a thoroughness which has since become characteristic in the organization and development of electrical and transmission work in southern California. The most notable work of a similar nature to that proposed, and which was also under contract for building at that time, was the 10,000 volt, twenty eight mile and single phase incandescent lighting plant of the San Antonio Light and Power Company, familiarly known as the Pomona plant. This plant, which was, as stated, being installed, was built under the electrical engineering direction of Mr. A. W. Decker, who was also at that time in charge of the electrical work then being done in building the Mount Lowe Railway. Mr. Decker's qualifications and experience were such as to fit him pre-eminently for the position of electrical engineer of the new project at Redlands, and in June, 1892, he was employed in that capacity.

| |||

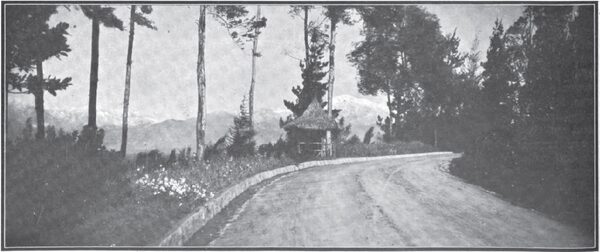

| A Beautiful View of Redlands and the San Bernardino Mountains is Had From Any Driveway on Smiley Heights. |

The Redlands electric Light and Power Company was incorporated in the spring of 1892 by residents of the town of Redlands in San Bernardino County, "for the purpose of supplying electric light and heat for both public and private use, power for manufacturing purposes and for the operation of street railroads and the city of Redlands in the country round about with a radius of ten miles," such power to be developed from a transmission plant that was to be built at the mouth of Mill Creek Canyon, some eight miles distant. At Redlands was a promising city with a population of 4500 people, and was lighted solely by oil and a few private gasoline plants. Coal was worth $11 a ton, and although the town was a small one, its prospects were exceedingly bright. It was further borne in mind by the promoters of the enterprise that the cities of Riverside and San Bernardino, each of a population of about 10,000, were comparatively nearby, that it is at a distance by rail of fifteen miles and nine miles respectively. These were then lighted by electricity generated from a water power developed from the irrigation canal which supplied Riverside, and the amount of power so obtained was a very limited quantity. The towns were then connected with each other and Redlands by a steam motor road, which it was hoped would eventually be changed to an electric railway system, to be operated by power developed at the Redlands plant.

It just interesting to note that of all the cities which have grown up in the western part of the United States in the ten years prior to the organization of the Redlands company, there have been none whose growth was more rapid than that of the city of Redlands prior to 1893, and a greater portion of the land included in the city limits of the town, which comprised about seventeen square miles, had never been turned by a plow, but early in 1887, began an influx of an active, well educated and well-to-do class of men who had and he six years which intervened built-up a town that is remarkable for its beauty of location, handsome some residences, well paved streets, substantial business blocks, and above all, for the superior quality of its oranges, which are equal, and by a great many considered the superior, in appearance and quality of those shipped from any other part of the United States. It possessed, unfortunately, a sad lack of inducements for manufacturing enterprises, and this, coupled with the reasons which have been named, led to the organization of the company which hoped to be able to furnish power to manufacturing industries at a price equivalent to that end localities where coal is $4.00 dollars a ton.

| |||

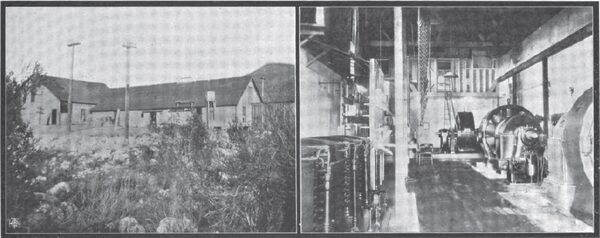

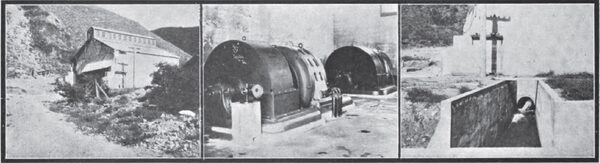

| The Original Redlands Plant As It is Today |

The first reality which gave assurance of the soundness of the ideas which underlaid the project, was the fact that they Union Ice Company, one of the largest handlers of ice in the western part of the United States properly entered into a contract with the Redlands Electric Light and Power Company to furnish electric power under a twenty-five year contract at a price that was so much cheaper than that which could be obtained elsewhere, that the ice company could afford to pay $2.00 per ton freight on 7000 tons of ice per year and still deliver it in Los Angeles at a rate of 50 cents per ton cheaper then it could be manufactured there under the most favorable circumstances. This contract proved to be the foundation upon which was built the business of the now historic Redlands plant.

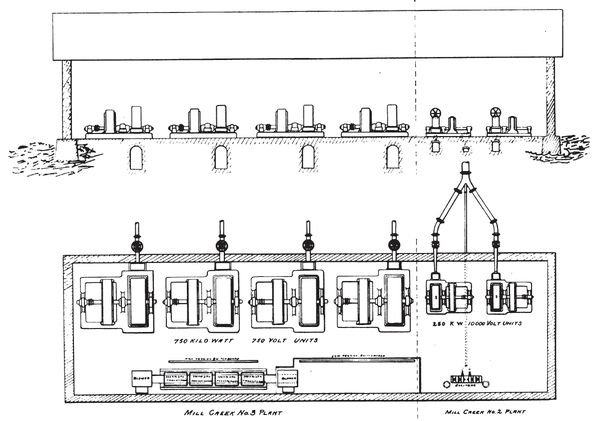

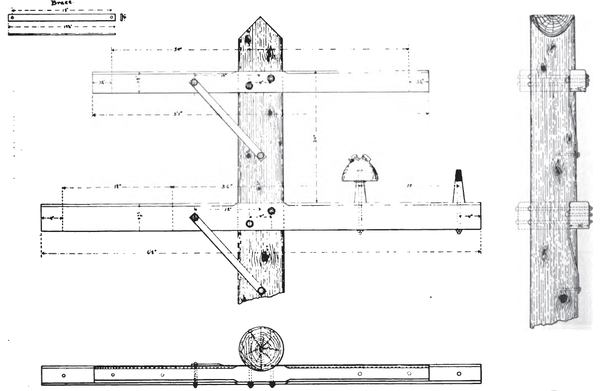

Mr. Decker's investigation of the local conditions attending the plan soon resulted in a conviction that the transmission itself would have to be carried out along lines radically different from those which characterized not only the Pomona plant but also any other plant in America. The Redlands plant must be designed essentially as a power transmission plant, and accordingly Mr. Decker recommended the installation of a three-phase and transmission system having a rated capacity of 400 kilowatts. Preliminary plans and specifications for a plant of this kind were prepared by Mr. Decker and submitted to the General Electric Company, the Westinghouse Electric and Manufacturing Company, the Siemen & Halske Electric Company and the Electrical Engineering Company, of San Francisco. It took several months of active correspondence between Mr. Decker and the companies named before they would agree to submit bids on an installation of this kind, taking the ground generally that details were not yet sufficiently worked out to justify then them in bidding along such a plant, and recommending the use of such apparatus as was standard at that time. Bids were finally put in by the Westinghouse and General Electric companies and the Electrical Engineering Company, of San Francisco, the latter proposing a 5000-volt direct current generating and transmission system, with direct current motor operating single phase alternators in Redlands. The bid of the General Electric Company for two 250 kilowatt, 2400-volt, 600 revolution, three phase, Y-connected generators was accepted, and the execution of the contract formed the members of the famed Redlands plant. The bid of the Westinghouse company was for a two-phase system, which Mr. Decker would not entertain. This original plan, which is now known as Mill Creek No. 1 station of The Edison Electric Company, was driven by Pelton water wheels, and the transmission line consisted of two, three-phase circuits, each being of three No. 0, B. & S. gage, bare copper wires running to Redlands, a distance of seven and one-half miles by way of the pole line. Common deep groove, double petticoat, 2,200-volt glass insulators were used. The distribution at Redlands was tapped off the end of the land with out any substation, they delivered potential being 2300 volts. Both light and power where thus delivered, but the principal power service from this original plant consisted in the installation of a 120-kilowatt, three phase, synchronous motor for operating the manufacturing plant of the Union Ice Company. This motor also operates at 2300 volts, the distance from the station to the ice plant being practically four and one-half miles.

At the time of installation the switchboard was equipped with a General Electric Company with generator switches consisting of common 500-volt, triple-pole, double-throw switches, such as had been previously used in railway work, this being the best type of switch manufactured at the time. These switches could never be pulled on a load at the machine voltage, and as the busbars were and duplicate, when it became necessary to change over the station operators were compelled to break the filled circuit on the machine and shut down the plant. There is now on the system of Redlands company the first three-phase generators, the first synchronous motor and the first induction motor ever turned out for commercial use by the General Electric Company, and it is interesting to note that they are still in daily service as installed, with every indication that they will continue in their duties for years to come.

On another page there is published a biographical sketch of the life of A. W. Decker, the electrical engineer who drafted the electrical specifications under which the Redlands plant was built, and it is suggested that this sketch be read in order that an idea may be gained of the difficulties which were encountered at this early date in securing the installation of the three-phase plant, and that the work then performed by Mr. Decker and this conjunction may be given proper credit. At the same time it is interesting to review the memorandum of conditions and requirements of this plant as laid down by Mr. Decker prior to its installation. It is pointed out therein that the power of available under the then present developments at the minimum flow of Mill Creek measured 1000 miners inches, or 1200 cubic feet per minute, under an affective head of 295 feet, from which the total capacity of the power plant was estimated at 359 kilowatts. It was also shown that the total output of the plant made by an estimation of a pipe line, which was afterward checked, could be measured to twice that shown during the whole year, and that during six months of the year approximately three times this amount of power could be obtained.

| |||

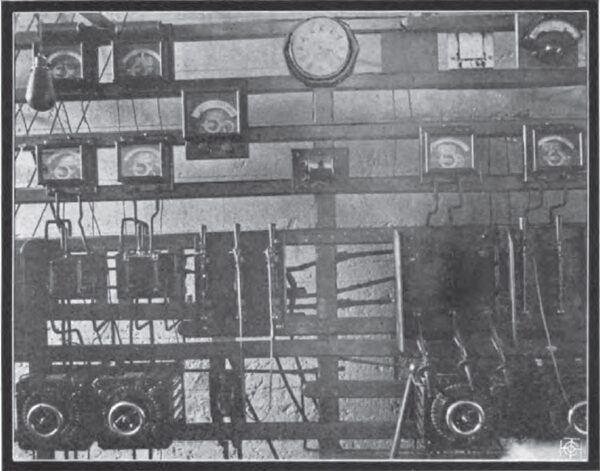

| The Original Switchboard in the Old Redlands Plant. Note the \"Growler\" Under the Clock |

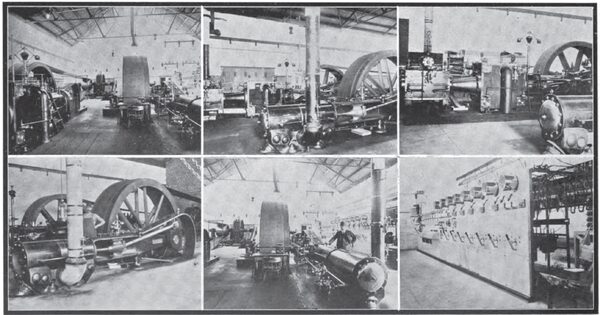

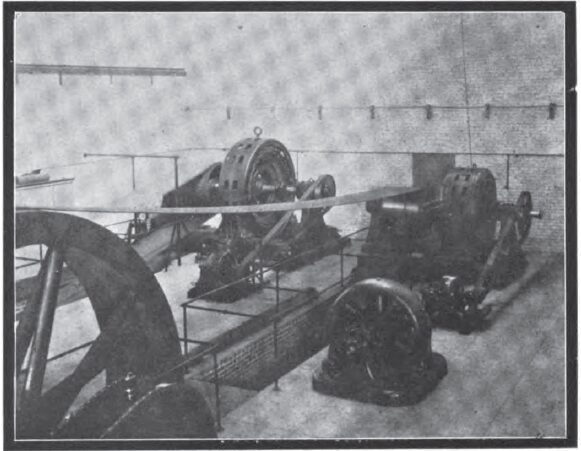

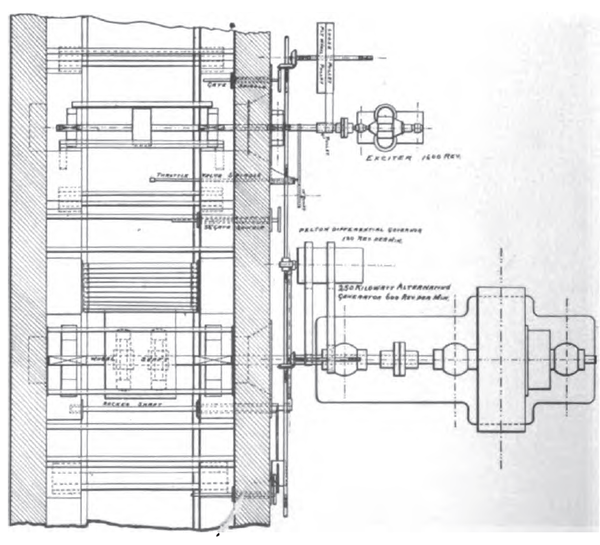

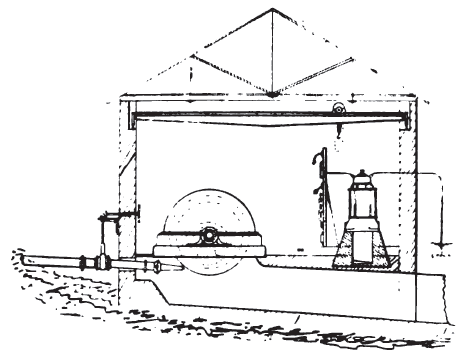

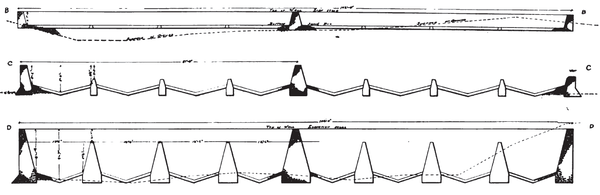

As already stated, there were first installed in the Redlands plant two 250-kilowatt three-phase generators, running at 600 revolutions per minute, and having a voltage of 2500. These machines were originally intended for belt driving, but, instead, they were installed with three bearings and direct-connected to Pelton water wheels, which were mounted in pairs directly connected through insulating couplings to the generators, and supplied with water from a receiver through a Y nozzle of the deflecting type. There were also two 7 1/2-kilowatt, 125-volt, compound wound exciters, that were separately driven by independent Pelton wheels, and which ran at a speed of 1600 revolutions per minute. The plant was governed by the old style differential governor, which was a familiar accompaniment of Pelton water wheel installations ten years or so ago. This mode of connection is shown in the accompanying line drawing, and its principle of action was that it was given a fixed speed so that the governor always tended to bring the nozzle to a position to correct the differences and speed between that of the generator and a source of constant speed. The unit which was selected for furnishing the constant speed was the exciter shaft, for the reason that exciter under normal conditions has a fixed load and practically a constant speed.

At the time of the writer's visit to the plant last winter the original switchboard had been dismantled and its parts stored, but in order that a faithful reproduction of the it in its original appearance might be given, the board was reassembled, and it has from this reassembled equipment that the accompanying halftone was made. It was, as the illustration shows, of the skeleton type, and there was mounted thereon a rheostat and triple-pole, double-throw switch, three ammeters and one volt meter for each machine, these instruments being of the Thomson-Houston type, and, as already stated, of the farm law of 500-volt railway apparatus them in use. The board was further equipped with two double-pole, double-throw line switches and three ammeters for each line, as well as being provided with double busbars.

Probably the greatest controversy that arose in the equipment of this plant, and after Mr. Decker had been forced by the manufacturing companies to recede from his demand for the direct generation of 5000 volts in a three-phase machine, was that due to the clause in his specifications which exacted the installation of generators of the three-phase type that would work in parallel. This procedure was declared by the chief engineer of the General Electric Company, before the Board of Directors of the Redlands Electric Light and Power Company, and the strongest terms, to be absolutely impossible of accomplishment, and it is interesting, indeed, to hear that relation of experiences that were encountered after the installation of the machines in the endeavor to parallel them. All kinds of expedients were resorted to in order to bring about some indication of the synchronism, and finally the General Electric Company produced a device, which became known as the growler, as being the best for accomplishing the result desired. This growler, which is illustrated herewith, was an attempt at an acoustic instrument, and in it the two separate phases which were to be synchronized were made to operate upon sheet iron diaphragms, placed several inches apart facing each other, the whole being enclosed in a sheet brass cylinder. At the center was cut a hole about an inch diameter, to which the station operator was to apply his ear, and it was expected that the operator could distinguish when the vibrations were in unison. In each of the upper corners of the base-board there was placed a sixteen-candle power incandescent lamp, being burned respectively from two of the three phases, but these lamps were used merely as pilots. The device failed, however, for, owing to the various harmonics generated by the machines in the station, it was impossible to tell with any degree of accuracy when the machines were in synchronism, and this condition led to the eventual abandonment of the growler, which, however, is carefully preserved in the Redlands plant for gets historical value.

EXTENSIONS OF THE REDLANDS SYSTEM.

In 1896 the business of the Redlands company had grown so that an extension became necessary, especially for the purpose of supplying power for pumping purposes. The transmission system was extended from Redlands to Colton and Riverside, and three 100-kilowatt Wagner transformers were installed in the powerhouse for raising the potential to 10,000 volts for the Riverside transmission.* At the same time that pipe line of the plant was expanded 3000 feet, which increased the head by eighty-six feet, making a total static head of 510 feet, or a pressure of 230 pounds per square inch. The total length of the pipe line as thus extended is 10,250 feet, most of which is of riveted steel 30 inches in diameter at the same time Pelton wheels of a latter type were installed, and this plant, as extended, constitutes the present Mill Creek No. 1 station of the Edison Electric Company.

|

| The Pelton Wheels, Generators and Exciters Were Thus Arranged in the Original Redlands Plant |

Three years later, in 1899, the further growth of the business of the company had necessitated the building of the second station, now known as Mill Creek No. 2 station, which is so located that the water from its tail race is taken up directly by the intake of the pipe line and a Mill Creek No. 1 plant. The second plant contains to 250-kilowatt, revolving field, 11,500 volt, three-phase generators, running at 375 revolutions per minute. They were put in operation in November 1899, and though they have been in constant operation ever since, they have always given perfect satisfaction and have never caused one cent for repairs. It is in an extension to the building of Mill Creek No. 2 station that Mill Creek No. 3 plant is now being rapidly finished, and when this latter plant is running it will be noteworthy as being driven under a higher head of water than any other electric transmission and the world, namely, 1960 feet.

* THE JOURNAL, Volume IV, page 21, MAY, 1897.

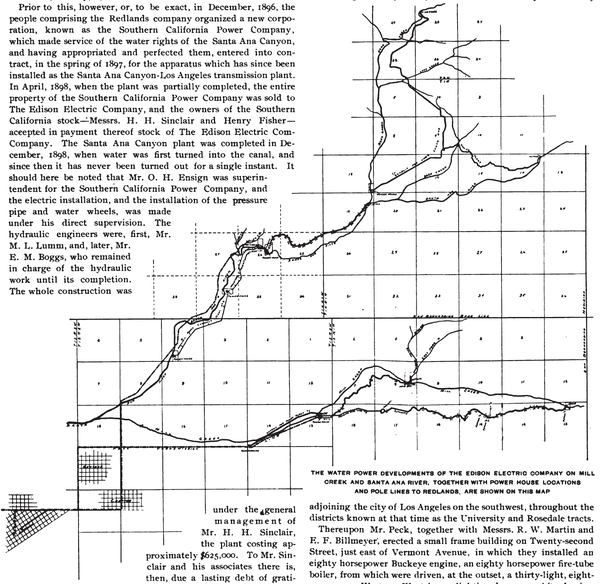

Prior to this, however, or, to be exact, in December 1896, the people comprising the Redlands company organized a new corporation, known as the Southern California Power Company, which made service of the water rights of the Santa Ana Canyon, and having appropriated and perfected them, entered into contract, in the spring of 1897, for the apparatus which has since been installed as the Santa Ana Canyon-Los Angeles transmission plant. In April 1898, when the plant was partially completed, the entire property of the Southern California power company was sold to The Edison Electric Company, and the owners of the Southern California stock - Messrs. H. H. Sinclair and Henry Fisher - accepted in payment thereof stock of The Edison Electric Company. The Santa Ana Canyon plant was completed in December 1898, when water was first turned into the canal and since then it has never been turned out for a single instant. It should here be noted that Mr. O. H. Ensign was superintendent for the Southern California Power Company, and the electric installation, and the installation of the pressure pipe and water wheels, was made under his direct supervision. They hydraulic engineers were, first, Mr. M. L. Lumm, and, later, Mr. E. M Boggs, who remained in charge of the hydraulic work until its completion. The whole construction was under the general management of Mr. H. H. Sinclair, the plant costing approximately $625,000. To Mr. Sinclair and his associates there it is, then, due a lasting debt of gratitude by the engineering world for the part they took in pioneering the development of polyphase transmission and America.

THE LOS ANGELES BEGINNING.

On the other hand, if the origin of The Edison Electric Company be considered from the standpoint of its development in the city of Los Angeles, it must be regarded as beginning in the spring of 1895, when Mr. E. E. Peck applied to the Common Council of the city of Los Angeles for a franchise for the purpose of enabling himself and his associates to build and operate an electric lighting and power plant within the corporate limits. After no little delay the franchise asked for was finally advertised, but Mr. Peck was not the successful bidder. Later in the same year he entered a second application for an electric lighting and power franchise, but the Council would not even advertise it, and so, for the time, his efforts were thwarted. Nevertheless his perseverance never flagged, and during the latter part of the year named he succeeded in obtaining from the Board of Supervisors of Los Angeles County a franchise enabling him to build and operate an electric light and power plant in a small territory and immediately adjoining the city of Los Angeles on the southwest, throughout the district known at that time as the University and Rosedale tracts.

|

| The Water Power Developments of the Edison Electric Company on Mill Creek and Santa Ana River, Together With Power House Locations and Pole Lines to Redlands. Are Shown on This Map |

Thereupon Mr. Peck, together with Messrs. R. W. Martin and E. F. Billmeyer, erected a small frame building on Twenty-second Street, just east of Vermont Avenue, in which they installed and eighty horsepower Buckeye engine, an eighty horsepower fire-tube boiler, from which were driven, at the outset, a thirty-light, eighteen-ampere Western Electric arc lighting dynamo. After having installed and arc lighting circuit, they started in business in December 1895, with a load which reaches a "grand" total of five commercial arc lamps and three straight arcs, which latter were paid for by subscription by the residents thereabouts. Thus was made the Los Angeles beginning of the great system of the President Edison electric Company.

| |||

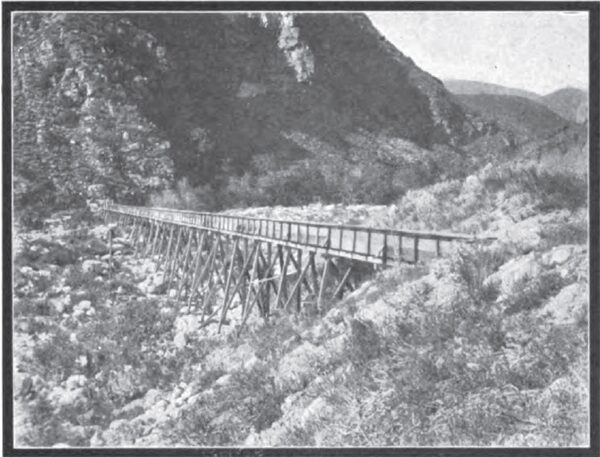

| This Flume Unites the Tail Races of Mill Creek Plants Nos. 2 and 3 With the Intake of Mill Creek Plant No. 1 |

But before starting this rather primitive electrical lighting plant, Mr. Peck was naturally looking for capital to aid him in its development, and as a result of his labors, Messrs. George H. Barker, W. R. Staats and W. S. Wright, of Pasadena, associated themselves with him, and in December 1895 a Fort Wayne 50-kilowatt 2000-volt alternator and some Fort Wayne transformers and Shallenberger meters of various sizes were ordered. In January 1896, Mr. E. Y. Ware came from Denver and joined in the enterprise, and under his direction the work of running a land to supply alternating current lighting service was begun. In the meantime Mr. Peck renewed his efforts to persuade the Council to advertise another franchise for sale, but without success. Nevertheless, the lines from the little plant were extended into the city by setting poles on private property and simply crossing the streets with the line wires, but the lines were harassed by competitors, and the city at last cut the wires. These were replaced as fast as cut, and they were finally let alone. Despairing of getting a franchise of their own for the city, the owners of the plant to finally bought an old franchise known as the Scott Franchise, in the spring of 1896. In order to fulfill its terms, they had but two weeks to get current into the City Hall, as the conditions of the Scott franchise were such that the municipal building had to be supplied with lighting current free of charge during the term of the franchise. To have secured the poles and built the long line necessary to reach the City Hall in that short time would have been a physical impossibility, and so, purely as an accommodation, permission was granted by the Los Angeles Traction Company which enable the plant to put its wires on the street railway poles of the Traction Company and thus it was that Mr. Peck and his associates were enabled to burn a cluster of lights in the City Hall on the night before the day on which the franchise would have lapsed had that not have been done. This was followed by controversy with the City Council as to whether it or the owners of the Scott franchise should prepare the City Hall for electric lights, but at last the Council finally decided to do it, which ended one important phase of the situation. Then the validity of the Scott franchise was attacked, and suit was brought to annul it, but this was finally settled in favor of the lighting plant, and so the controversy finally ended.

| |||

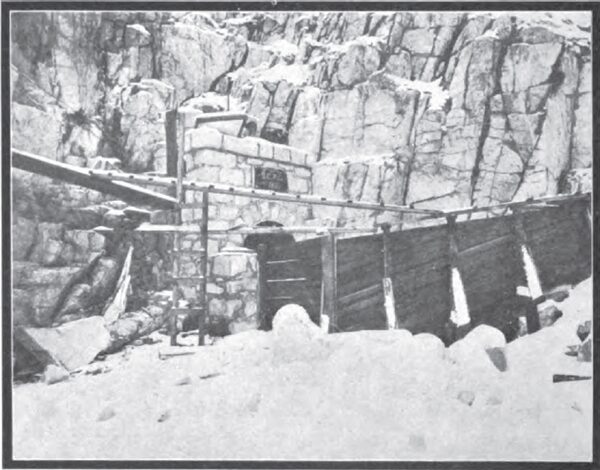

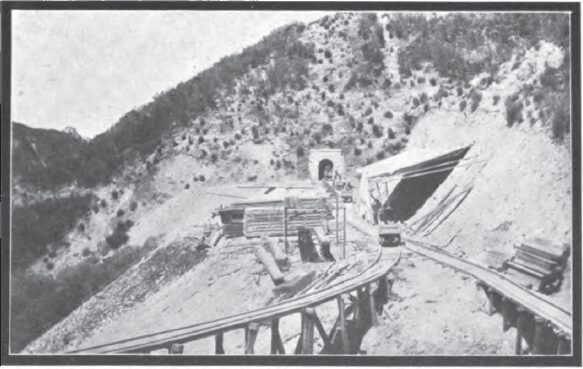

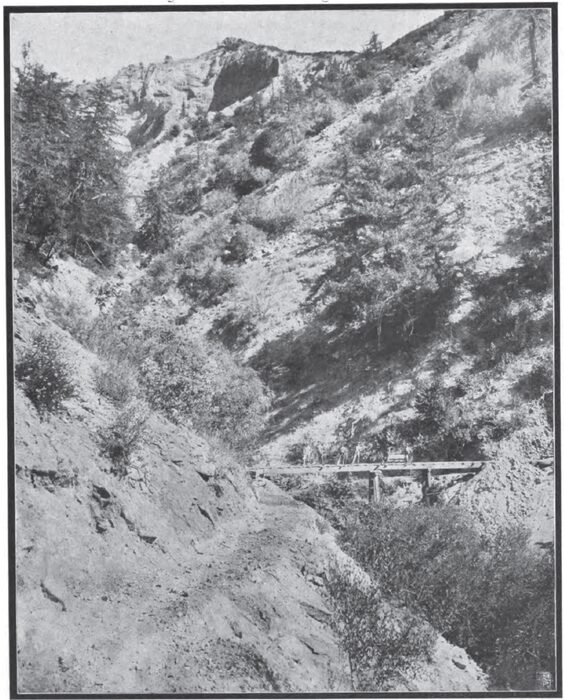

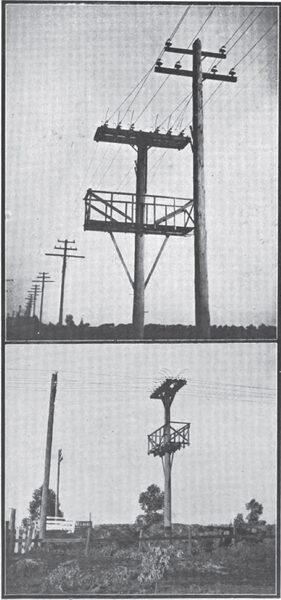

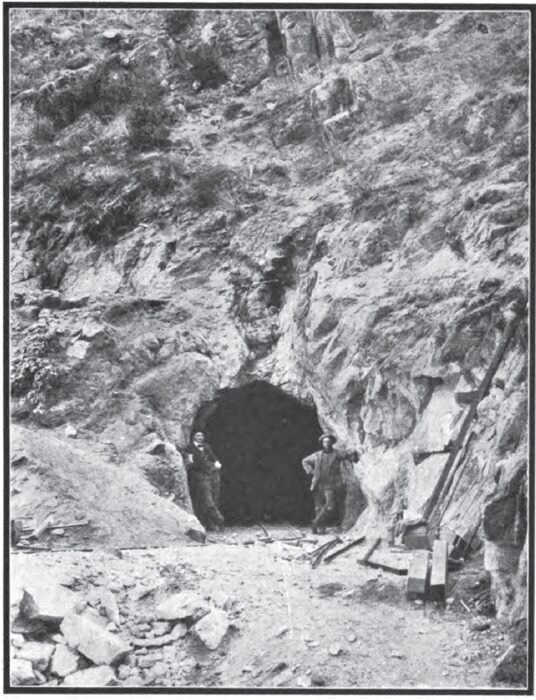

| The Portal of Tunnel No. 1 of Santa Ana Plant No. 1 |

To Messrs. Barker and Staats is due the credit for financing the project and its primary stages, and to Mr. W. S. Wright is due the credit for its legal work, both in the way of organization and in defending suits.

On June 5, 1896, the West Side Lighting Company was incorporated with a capitalization of $500,000, with George H. Barker, president; W. S. Wright, vice-president; W. R. Staats, secretary and Treasurer, and E. E. Peck and E. F. Billmeyer constituting the first board of directors. On July 6th, of the same year, Mr. Jason Evans succeeded Mr. Billmeyer, and on December 12th, Mr. J. H. Holmes succeeded Mr. Peck. On September 28th, also of 1896, a $300,000 bond issue was authorized, and the enterprise was launched into a solid, full-fledged corporate existence.

| |||

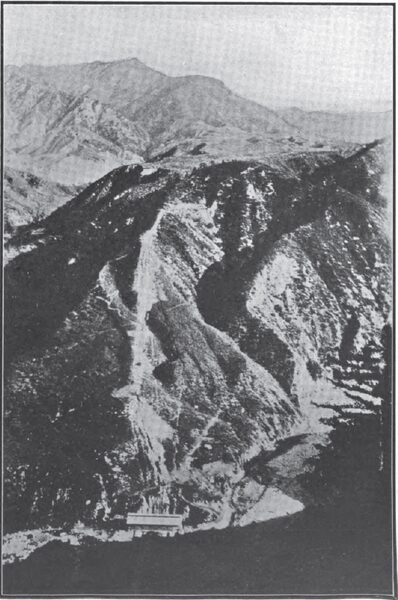

| Three Views of Mount San Bernardino and Mill Creek Canyon |

Soon after incorporating, a more central location for the plant was sought, and finally the old cable power house on the corner of Second and Boylston streets was purchased. The work of its transformation was rushed, and in December, 1896, the company began operations in its new location with two 90-horsepower Babcock 8 Wilcox boilers and a 60-horsepower Brownell open heater, one 150 horsepower Ideal Engine, and a 75-kilowatt, Fort Wayne, 2000-volt alternator. The old equipment was moved over from the frame building on Twenty-second Street, and an earnest campaign for business down town was begun. The business of the company increased so rapidly that in January 1897, two 200-horsepower Stirling boilers, one 175-horsepower Ideal Engine and one 120-kilowatt, General Electric, 2000-volt alternators were installed and a 150 horsepower Cochran Heater. In February, 1897, the old low tension arc dynamo was replaced by a Western Electric 9.6 ampere, 80-light arc machine and later a Wood 9.6-ampere, 80-light arc machine was added which were latter supplemented by a Brush 9.6-ampere, 125-light arc machine. In the fall of 1897 the company decided to go into the power business, and installed therefor, two 100-kilowatt, 550-volt, Westinghouse direct-current generators.

| |||

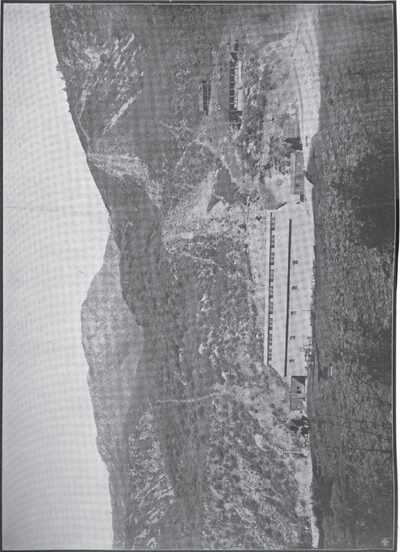

| A General View of Santa Ana Power Plant No. 1 |

In December, 1897 the West Side Lighting Company sold out to the Los Angeles Edison Electric Company, which had incorporated on July 9, 1894, with a capital of $500,000, it being necessary to assume that name in order to obtain the Edison licenses. The name was then changed to Edison Electric Company, which retained the old board of directors of the West Side Lighting Company, but others were taken on subsequently. It was about that time that Mr. John B. Miller, now president of The Edison Electric Company, entered the board, and was elected treasurer of the company, whereupon he at once became an important factor in financing the company to its present imposing position. Early 1898, another Stirling boiler was added to the steam equipment, as were also a 500-horsepower condenser and a 500-horsepower Day open heater. A 300-horsepower Ideal engine was purchased and utilized in driving a Westinghouse three-phase, 240-kilowatt, generator that had been supplied by the Southern California Power Company, with which The Edison Electric Company had contracted for power.

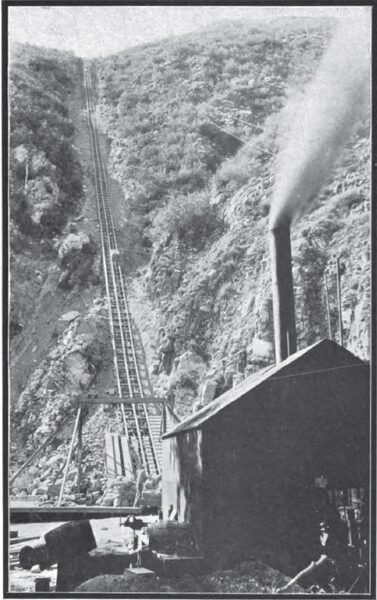

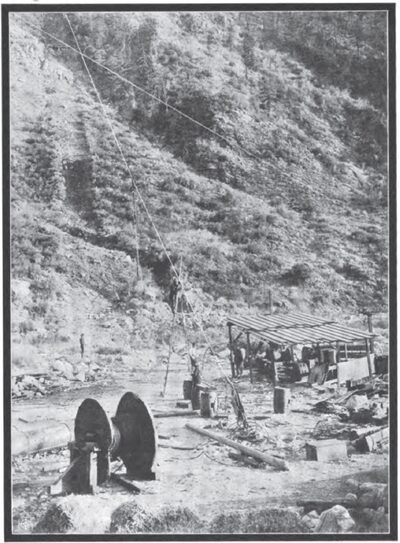

| |||

| Up This Tramway the Materials for the Pipe Line and Renstock of Santa Ana Plant No. 1 Were Taken |

Thus began the era of association between electric lighting and power interests of Los Angeles and power transmission interests of San Bernardino county, which eventuated in the consolidation of the two systems into a single enterprise which is second to none on the Pacific Coast in point of commercial and engineering importance.

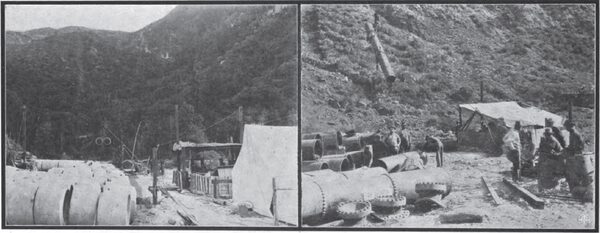

| |||

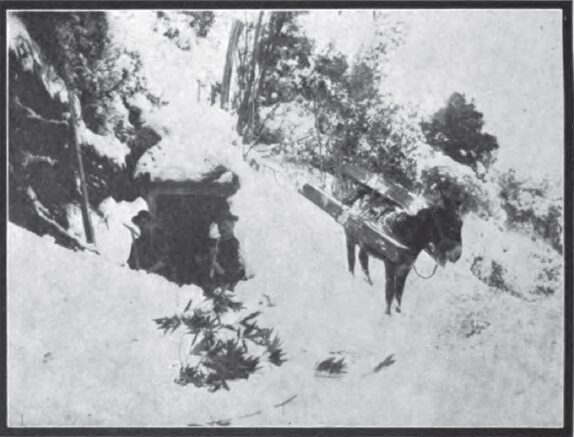

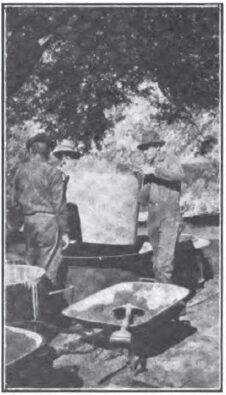

| The Construction of the Waterway of Santa Ana Plant No. 1 |

| |||

| A Winter Scene on the Line of the Canal of Santa Ana Plant No. 1 |

THROUGH MOUNTAINS AND ACROSS CANYONS.

It is a truly remarkable experience to go over the water courses of The Edison Electric Company in Santa Ana Canyon. Perhaps I might better have said through the water courses, for the tunnels are indeed the most interesting part of the whole work. The story of the great reservoir at Bear Valley, of its enormous storage capacity and of the Paradises which its waters have wrenched from arid wastes, is an oft-told tale* so I will not repeat it.

* For general conditions of the water supply of this section of southern California and data concerning its development for power purposes, see an article in The Engineering Magazine, Volume XIV, page 1011, by Mr. F. C. Finkle, March, 1898.

Less than three hours' drive takes one-figuratively transports one-from the beauties of Redlands to the grandeurs of the Santa Ana Canyon. First, by bowered houses, then past orange groves that fill the air with Eden and on we drive across and up the great river bed of the Santa Ana into its rugged canyon. The altitude and the deep shallows in the canyon make driving chilly — it is winter anyway but "a drink that will cheer" is promised us soon, and when time has given a sufficient whet to our longings, we reach the stopping place where "hot drinks" are served, fresh from a bubbling spring of boiling mineral water. Better toddy never was than this, so they say, and on we go past the power house and up to the intake of the canal. A few rods above is the confluence of Bear Creek and Santa Ana River, then comes the diversion with its gates and sandbox and directly the stream is swallowed by the gaping portal of Tunnel No. 1. Then we returned to the road and went back down the canyon for a half mile or so, and a short climb up the base of the mountain brought us again to the canal at the sand box, between the mouths of Tunnels Nos. 3 and 4. Here our boat awaited us, and, nearby, smoking restful corncobs and wearing great gum boots that reached the hips, were the three men who had spent the previous four hours in pushing this self-same boat up against the waters that rush on their way to the power house. And our party was to float down in that boat, like the rich in their chaises, while these men were to walk back, by gracious, but such is life!

|

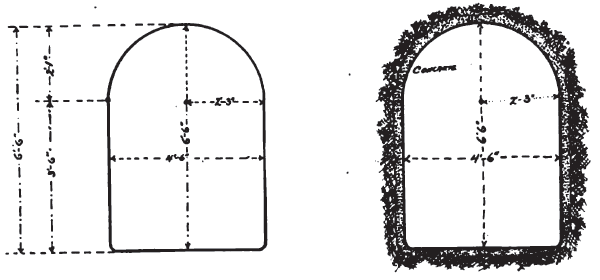

| Sections of Tunnels Santa Ana Plant No. 1 |

Plash! Plash! in measured time sounded the buckets of the paddle wheel that raked leaves from off the screen in the sand box, and to the tune of its slow beating one by one we backed down through a narrow opening into the boat hidden partly within the tunnel.

"Like crawfish, backing under a sheltering rock" quoth I.

"Like lobsters, attempting to escape being boiled alive" quoth my wife, who abhors tunnels and high bridges and uncanny adventures.

So we piled in, all five of us (there was room in the boat for as many more), and began a ride that was, to use the vernacular, the "very oddest ever." A man standing in the bow had a lantern and as the boat would approach the sides of the tunnel he would push it off to keep from scraping. We first-class passengers, seated on boards softened by a single spread of gunny sacking, and presumably entitled to all the priveleges [sic] privileges of the saloon of the ship, soon began to feel the cold, and there followed a mutinous outcry against a saloon which had no bar.

Then up spoke the worthy captain, "The bar's all right; you'll find it in due season."

On we drifted, ever onward toward that knothole of light perhaps a thousand feet down the tunnel through a seemingly interminable way of inky darkness.

"We'll have to be pretty long drawn out to escape through that hole," said sonic one. The current was rapidly becoming swifter and the wierd [sic] weird silence of the tunnel was giving way to the babble of rushing waters.

Then: "Here's your bar," said the captain. "Line up."

The boat scraped along the bottom for a time, then skewed from side to side and finally, with a rasping grunt, stopped stock still. But it was only for a moment, for the water, backing up at the stern, gave it a mighty shove that upset the composure and balance of we uninitiateds [sic] uninitiated and sent our craft merrily out beyond into the deep water of the tunnel.

"Is that the bar you promised us?" demanded one.

"You 'line up' your friends by leaving 'em lyin' down," observed another.

"What shall we do with him, fellow citizens?" demanded a third.

And the outraged passengers, like the people of ancient Rome, roared vengeance by hanging, killing, drowning and otherwise, until the captain promised to be good and "square matters" later.

| |||

| Screen Method of Removing Leaves and Debris From the Santa Ana Flume |

As on we went the knothole grew larger, and as the light and temperature increased, our senses mellowed to beauties of the scene through which we were passing. It chanced that the rays of the sun were falling squarely into the mouth of the tunnel from which we were about to emerge. The cement lining of the tunnel, faithful to its trust, made the sides and roof as dry as tinder, and tiny spiders, seizing the opportunity presented in the dry location and the prospect of rich harvests, had frescoed the walls with thousands of silken webs upon which the sunlight, reflected from the water below, shone in matchless iridescence.

| |||

| \"Plash! Plash! in Measured Time Sounded the Buckets of the Paddle Wheels That Raked the Leaves From Off the Flume\" |

We were silent now, and joking could not be, and on we leisured, from darkness through glories into the warmth of the God's blessed-sunlight which marked our delivery to the flame. Didn't the warm air feel good, though, and wasn't the balm of the mountain foliage delicious, even if we got but glints of them through the timbering of the flame as we still drifted onward.

Then some one said that we had come literally as from night to day. Another thought it was like turning from the chrysalis to the butterfly. Then others indulged in such cheap talk as anent the egg and the chicken, and the jackass that was born down in the coal mine, butt which at last was taken up above ground. And when each was asked if he felt like the poor Jack, such is the contradiction of human nature that not one would answer aye.

| |||

| Two-Way Sand Box in Santa Ana Canyon Below the Intake of Santa Ana Plant No. 1 |

Thus were scenes repeated as we journeyed down that wondrous waterway. Some tunnels were short, some were long and one of them - the longest of all - stretched out to a length of over 2000 feet, and in its center we were some 1500 feet beneath the surface of the mountain above. The further down we went the higher grew the elevation of the flumes above the river, until at last, in looking over the sides, it was dizzying to contemplate the more than 700 feet of abyss that yawned invitingly beneath us. In all, there are eighteen tunnels and sixteen flumes in this waterway, which aggregates a length of 14,384 feet or practically two and three-quarters miles, and the time consumed in making the trip down it by boat was twenty minutes.

We did not go through the final tunnel, for the water was backed up at the penstock that the tunnel was filled to its roof and indeed it was very "low bridge" in the next to the last tunnel which we traversed. Next came an arduous climb up and around the mountain on which the pipe line was placed, then to an equally arduous descent down the pipe line to the power house where, thanks to a thoughtful host and hostess, dinner was awaiting our arrival. And you may be assured that after we had finished there was no dinner left to "warm up" for supper.

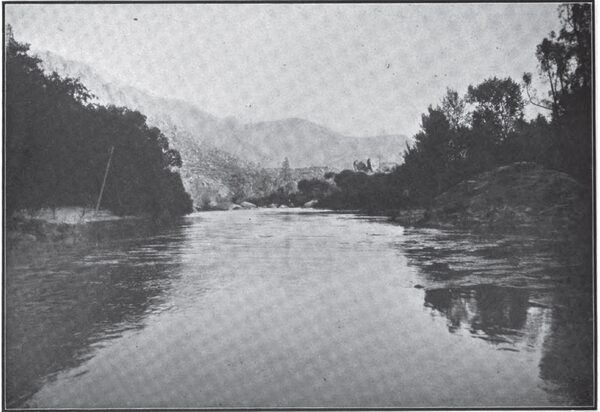

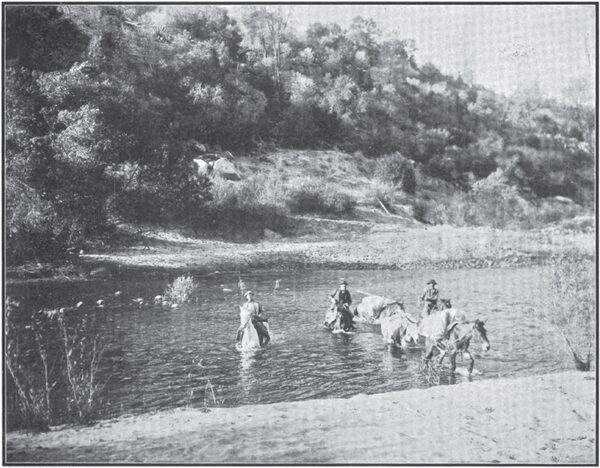

Topographically, Mill Creek Canyon differs radically from, Santa Ana Canyon, for while the latter below the junction of the Santa Ana River and Bear Creek is virtually a barren ragged mountain gorge, through which the waters rush almost torrentially. Mill Creek is a stream of goodly size and of very even temperament in its flow. That it should be so becomes evident to any one who has driven up along its beautiful course, for here instead of bleak rock, rock, rock everywhere, as exists in Santa Ana Canyon, there are alders and cottonwoods and hazels and shrubbery galore, which 'neath the foot ferns and mosses thrive luxuriously. It is a most beautiful canyon, wherein through the long summer months campers find a matchless Mecca. Its soil, deep and absorbent, stores up the winter rains and the melting snows of spring to give them back through the summer and autumn months, and thus it is that Mill Creek has been endowed by Nature with its perennial flow. To the north, the grizzled side of old Mount San Bernardino rears to its mighty eminence, and, like the southern sides of all mountains in the southern part of the State of California, it is Covered only with rock that is bare except for the chapparel [sic] chaparral and greasewood that grows here and there. But across the canyon on the northerly exposure all is different, for there vegetation is shielded from the blanching rays of the sun and it thrives in utmost glory, from the tenderest maiden hair and lichen to the sturdiest oak and pin.

HYDRAULIC CONDUIT, SANTA ANA CANYON PLANT NO. 1.

The hydraulic conduit supplying water to power plant No. 1 of The Edison Electric Company, in Santa Ana Canyon, which was completed in the year 1898, begins at the junction of Bear Creek and Santa Ana River. The diversion of the water is made by means of two branch flumes, one carrying the waters of Bear Creek, and the other one, those of the Santa Ana River, to the junction where they are delivered into tunnel No. 1 at the head of the conduit. The water is delivered into these flumes by means of dams placed across the two channels. It is the purpose of the company to construct a dam across the canyon immediately below the junction of the two streams which will raise the level of the water sufficiently to do away with the two flumes. When this dam is constructed the water will be raised by means of it to a level which will deliver it directly into tunnel No. 1, hence it will flow as at present down the canal.

| |||

| The Longest Flume on the Waterway of Santa Ana Plant No. 1 |

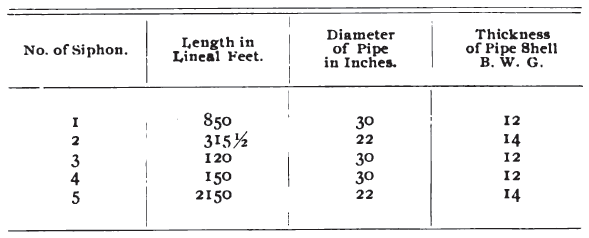

The line of the conduit consists of eighteen tunnels driven through the various spurs of the mountain side, extending from the junction of Bear Creek and Santa Ana River to the head of the pressure pipe, and of a number of flumes spanning the canyons between the various tunnels. The length of the various tunnels on this conduit are as follows:

Tunnel No. 1, 220 feet; tunnel No. 2, 460 feet; tunnel No. 3, 700 feet; tunnel No. 4, 530 feet; tunnels Nos. 5 and 6, combined, 900 feet; tunnel No. 7, 900 feet; tunnel No. 8, 2070 feet; tunnel No. 9, 730 feet; tunnel No. 10, 850 feet; tunnel No. 11, 700 feet; tunnel No. 12, 840 feet; tunnel No. 13, 210 feet; tunnel No. 14, 540 feet; tunnel No. 15, 220 feet; tunnel No. 16, 780 feet; tunnel No. 17, 560 feet; tunnel No. 18, 830 feet; total, 12,040 feet.

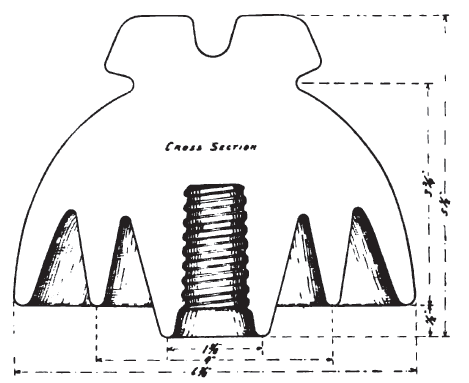

All of these tunnels are lined with concrete throughout so as to give a net width of four and one-half feet and a net height of six and one-half feet. The method of construction is shown in the drawing of tunnel sections appearing on page 17, and in the illustration of the portal of tunnel No. 1 appearing on page 14 of this issue. The carrying capacity of these tunnels is 120 second-feet of water, which will generate at the power station 6000 horsepower. The tunnels are all connected by means of flumes spanning the ravines. The carrying capacity of the flumes is the same as that of the tunnels - 120 second-feet of water.

The conduit has been constantly in use since the latter part of the year 1898, and it has never been found necessary to turn the water out for the purpose of making repairs to the work. After the water is admitted at the head of the conduit it is passed through a sandbox or settling basin where the sediment is allowed to precipitate before the water is carried on to the power plant. This sandbox consists of two parallel hoppers with sluice gates in the bottom through which the accumulated silt can be expelled. The water is passed through one hopper while the other is being emptied, thus causing no interruption of the flow of water while the sand sluicing is in progress.

| |||

| Sand is Flushed Out Through Holes in the Bottom of the Sand Box |

Above the intake of this conduit is a tributary watershed of 172 square miles, raning in elevation above sea from 3500 to 12,000 feet. On the upper portion of Bear Creek is a storage reservoir regulating the discharge from fifty-four square miles of this watershed, storing the winter flood and permitting the water to be discharged during the dry season when most needed. The Bear Valley reservoir has a dam fifty-four feet in height and a storage capacity in the basin behind this dam of 9,778,440,000 gallons. All the water flowing from this reservoir must pass down Bear Creek to the intake of the Santa Ana conduit and power plant No. 1, whence it is diverted and carried down to the power house combined with the flow of the Santa Ana River.

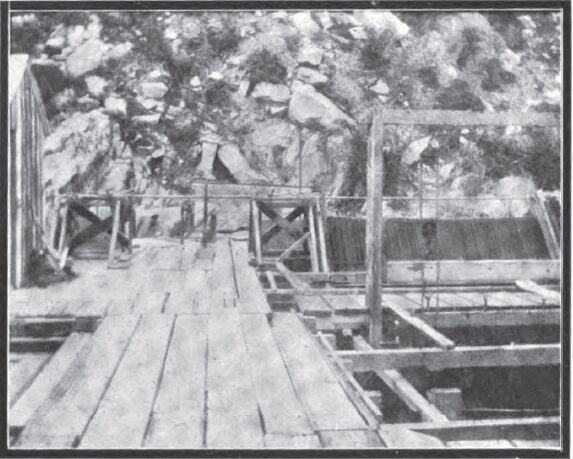

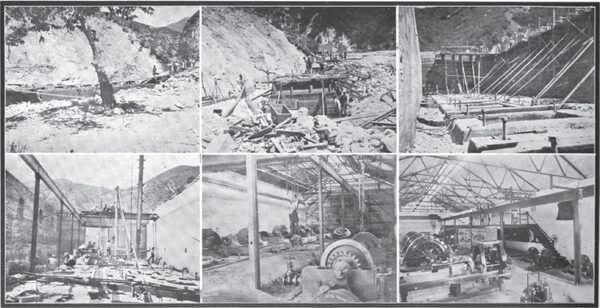

| |||

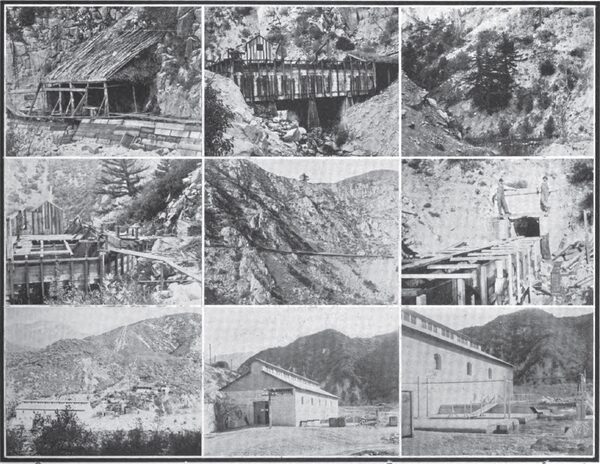

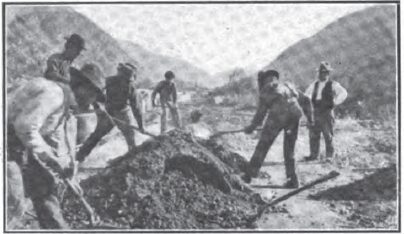

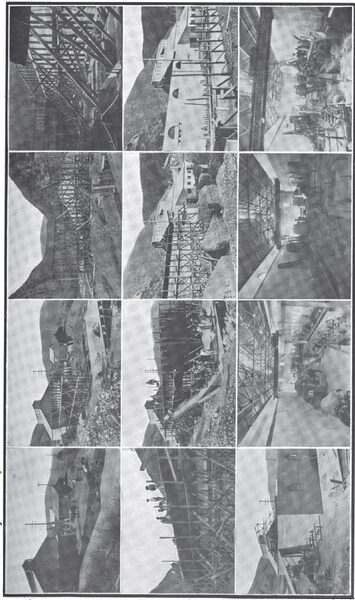

| From the Commencement to the Completion of Santa Ana Power House No. 1 |

Below the intake tunnel, where the water is run through the sand box, there is a large grizzly having a cross section of thirty feet by seven feet, and over which there travels a rake every quarter of a minute, this rake being driven by a paddle wheel placed in the main canal. The arrangement has proven so effective in heavy storms which occur in the beginning of the winter season, causing the water to bring down quantities of small debris, that, although it has sometimes happened that the headworks men could not give the sand much attention for seven hours, they have at the end of that time found the penstock to be perfectly clear of leaves and driftwood, and as a result the plant has never suffered interruption. This sandbox peculiar in that it consists simply of two large rectangular reservoirs, the bottom of which are divided into several small compartments which have a depth of two feet. The sand box has a grade of two feet in fifty, and at the lower end of the compartments named there is a plug valve eight inches in diameter, which is provided with a stem that runs up through the water to the board walk above. This valve is lifted by a small block and tackle, which opens the hole in the bottom of the compartment, and as the water can be turned into each compartment, it is an easy matter to clear the box of sand in a very few minutes with a small amount of water. So effective and simple is this arrangement in operation that no trouble whatever has been caused by sand, which, however, would not otherwise be a great source of trouble except during a few weeks of winter storms when the canyon stream becomes torrential.

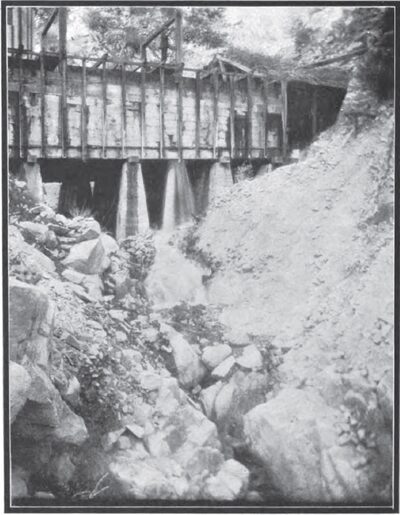

THE PIPE LINE IN SANTA ANA CANYON.

It is a very precipitous mountain which overtops the location of the power plant of The Edison Electric Company in Santa Ana Canyon, and, as is the case will all high head power plants, the station is situated at the base of the mountain, which, in the present instance, gives a fall for the pressure pipe of 728 feet, the water being conveyed in a thirty-inch steel riveted pipe which has a length of 2210 feet. This pipe begins at the end of tunnel No. 18, which has a length of 1260 feet, and in which the water is backed up to a depth of six feet. The pipe line at the penstock is of three-sixteenths-inch steel, and terminates at the power house with a thickness of nine-sixteenths of an inch. It is double-lap riveted in the longitudinal seams throughout, and single riveted in the round seams, and is protected by thoroughly dipping in a mixture of asphaltum and crude oil. Moreover, the pipe line is buried throughout at an average depth of seven feet firm ground, which is of such solid nature that no other anchoring further than the weight of the earth upon it is necessary.

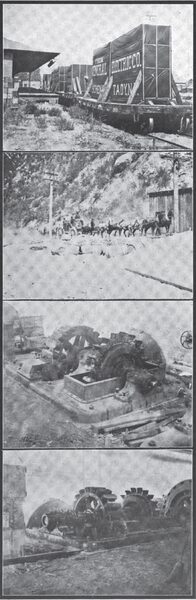

| |||

| A Series of Views of Interesting Features of Santa Ana Plant No. 1 |

It is laid in almost a straight line; in fact, it contains no angle greater than ten degrees. As to the method of laying this pipe line, it was started from a point about seventy-five feet from the power house and laid up the hill. The last joint was connected into the power house by riveting in a collar on a warm day, and, as much as all the pipe above had been buried, there was no chance for the pipe to move down hill and thus put a strain on the power house fittings. The second pipe line, parallel to the first one, is still to be installed, and preparations have been made in which it will enter the receiver. The receiver is the same diameter as the pipe now installed, and sets at right angles to it, and water for one unit is taken directly from in front of the pipe line, with one unit on either side. Although this arrangement necessitates making a right angle at the tee, practically no drop in pressure results from this angle. In fact, the drop in pressure is by test only a pound and a half. It will be practicable to shut off the valve on either pipe line and empty it for repairs or inspection without interruption to the plant. A valve will also be placed in the receiver, dividing it into two halves, each fed by one pressure pipe, and so arranged that water for the exciter wheels can be taken from either half. At the head of the pipe line there has been placed a gate, consisting of a rectangular piece of boiler plate working in brass slides, and by means of which the water can be shut off from the pipe line. This gate is under electrical control and is operated by means of a push button placed in the power house. Its valves act by means of oil upon a ram, pressure being given to the oil by reason of a pipe line running to a storage tank filled with oil placed at an elevation of about 127 feet up the mountain side. While it would have been possible to have used water for this purpose during much of the time, it was deemed advisable to use oil, because it will neither freeze in cold weather nor cause either the cylinder or piston to rust.

THE HYDRAULIC FEATURES OF MILL CREEK NO. 1 PLANT.

The hydraulic features of Mill Creek Plant No. 1 were installed under the direction of W. C. Butler of Redlands, hydraulic engineer to the Redlands company, and, as first installed, the wheels were supplied with water at a head of 377 feet, but in 1896 the pipe line was extended a distance of 3000 feet up the canyon, which increased the head to 530 feet, and at the same time the Pelton wheels and nozzles were changed. The pipe line then consisted of 10,250 feet of riveted steel pipe, beginning with No. 12 gauge at the upper end and terminating in 5/16 at the receiver. The pipe line was thirty inches in diameter, while the receiver had a diameter of forty-eight inches, and upon it the nozzles were riveted. The water wheels were arranged underneath the receiver, with the wheel shaft set at right angles to it, and, the shaft being extended through the wall into the power house, the nozzles discharged into a common tail-race running longitudinally just outside the wall of the power house. At the time these alterations were effected a third machine of similar capacity was installed, and its mode of installation was the counterpart of that of the two previous machines, with the exception that it was given two bearings.

| |||

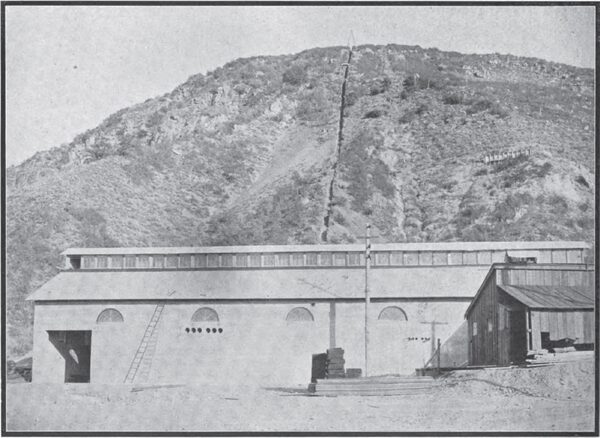

| Santa Ana Power House No. 1, Showing Pipe Line Trench and Reservoir for the Lombard Governors |

THE HYDRAULIC FEATURES OF MILL CREEK NO. 2 PLANT.

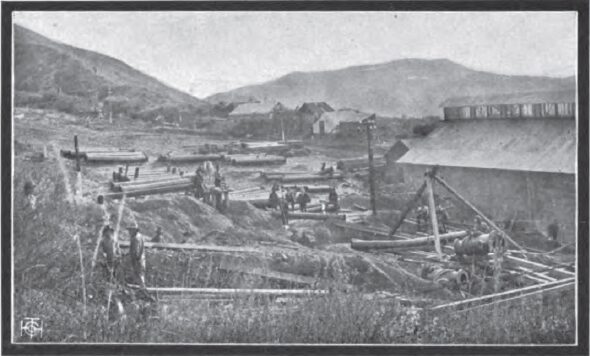

It was in 1898 that the load which had been thrust upon the original Redlands plant became so heavy as to make it imperative that further power should be developed, and fortunately the location of Mill Creek was such that all the water which ran through plant No. 1 was susceptible to prior use by diverting it further up the canyon and applying it at a new location, known as No. 2 plant, which could be situated so that the water from its tail-race would be immediately taken up by the intake of the pipe line of No. 1 plant. In line with this policy the construction of Mill Creek plant No. 2 was begun on the 24th day of October, 1898, and it was completed upon the 1st day of September, 1899, having been carried on continuously between those dates.

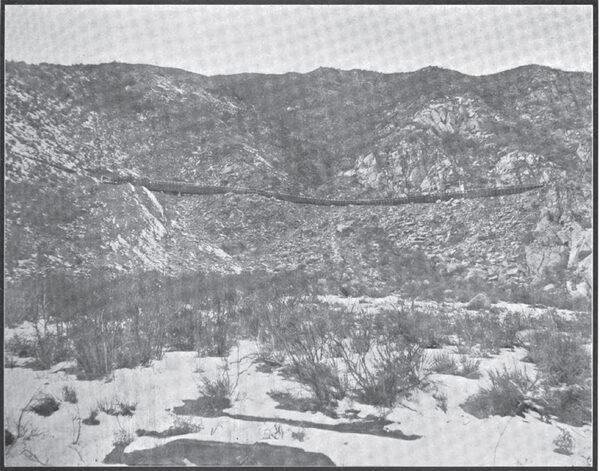

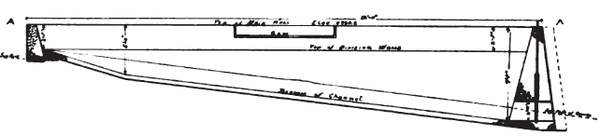

The map on page 13 gives not only the location of the power plants of The Edison Electric Company in San Bernardino County, but also shows the routes of Santa Ana River and Mill Creek, as well as the locations of their waterways and diversions. The water from Mill Creek No. 2 plant is diverted by means of a tunnel about 400 feet in length, the upper end of which under the bed of Mill Creek at a depth of eighteen feet below surface. This tunnel collects the underflow of the stream intercepting it as it passes through the voids in the gravel and comprising the channel. The surface flow is diverted in a tunnel through a shaft communicating with the level in the tunnel and located near the bank of the stream. This is lined with concrete and has a grating of steel T-rails in top adjoining the stream, through which the water enters it, and by means of this grating all debris and rocks are excluded from the shaft and tunnel. There is also a gate for regulating the amount of water entering the shaft, placed just outside of the grating. A concrete dam three feet above the level of the channel deflects the water into the shaft. There is a sluice gate in this dam, by the opening of which the water passes down stream instead of into the tunnel. The tunnel is partly in solid rock and partly in boulders and gravel, being timbered concrete lined with the latter.

There are twenty-two flumes along the line of power plant No. 2. These are for crossing ravines and flats lying below the grade line and passing along the sides of certain rocky and precipitous cliffs. They are each from twenty-two to 400 feet in length and usually consist of sixteen-foot spans. In some cases where footings for the trestles could not be found that close together the spans are made thirty-two feet long and supported by hog-chain trusses. The dimensions of flume are thirty-six inches wide by twenty-six inches deep, the flume box being constructed of one-and-one-half-inch clear surfaced redwood, placed in position longitudinally to the flow of the water. The trestle caps, stringers and yokes are all of clear Oregon pine, and footings for trestles are constructed of cement concrete. Flumes in exposed places are heavily covered with planks and timbered from two to six inches in thickness. Such covering is for the purpose of protecting the flume against rolling boulders and landslides.

Flume No. 1 is located between the intake tunnel and the sand box. All the other flumes are in the conduit below the sand box, being distributed throughout the entire line. The most notable and picturesque of these flumes is the one known as Sheep Cliff flume, which is constructed along the side of a nearly vertical cliff. The total combined length of all the flumes on power plant No. 2 is three-fourths of a mile.

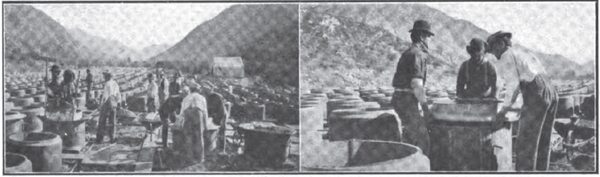

| |||

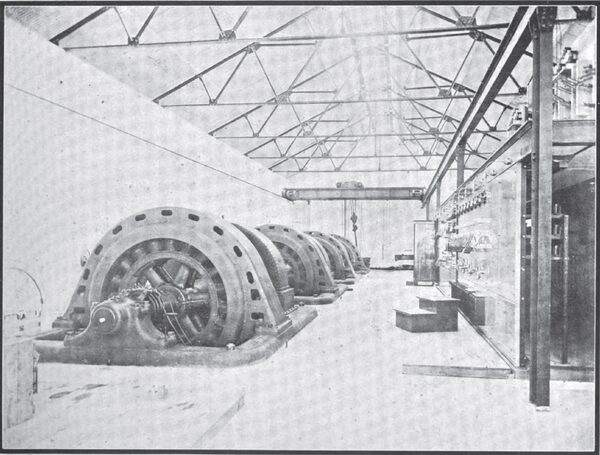

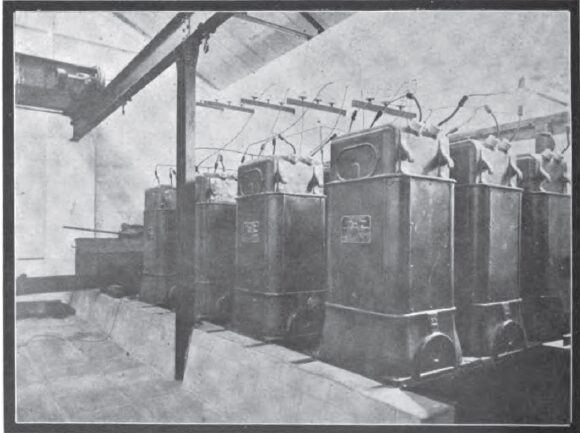

| The Interior of Santa Ana Power Plant No. 1 |

The remaining portion of the gravity conduit not in flume consists of Portland cement concrete pipe having an internal diameter of twenty-two inches. The length of such concrete pipe is two and one-quarter miles. The pipe was made in two-foot sections with a thickness of shell of two inches. The material used was the natural gravel and sand taken from Mill Creek wash, screened through one-and-three-quarter-inch mesh, three parts, and Portland cement, manufactured at Colton, Cal., one part, by measure. After the materials were properly wet, and thoroughly mixed, the pipe was made in forms such as are ordinarily used for the purpose. When time for curing had elapsed, the pipe sections were hoisted, two for each trip, on a standing line cable extending from the bottom of Mill Creek Canyon to the trench grade on the mountain side above. From the platform at the upper end of hoists the pipes were rolled in the trench to the place where they were used. Joints used in laying the pipe were of the Ogee type, with heavy cement collars on the outside and smooth finish inside.

At the intake of the pipe, below the sand box and at the lower end of each flume, taper pipes from twenty-six to twenty-two inches inside diameter were used for the purpose of overcoming any possible loss of carrying capacity due to entry head. The trenches were laid out in such a manner as to create no curve having a lesser radius than eighteen feet, while nearly all curves are of more than fifty feet radius.

The grade of the gravity conduit, both the flumes and pipe, is two-tenths of a foot per 100 feet, and the result of the construction of the flumes and pipes above described on this grade was to produce a conduit having a capacity of ten second-feet of water.

The maintenance of the twenty-two-inch pipe is made easy by manholes along the line, which are located at intervals of 500 feet. The pipe, after being laid, was covered with from two to three feet in depth of soil and rock, which protects it from laud- slides and rolling boulders.

After passing through the intake tunnel and flume No. I the water enters the sand box or settling basin of concrete. This is twenty-two feet wide by fifty feet long and is divided into five compartments by means of concrete cross walls. The depth of the sand box is five feet along the upper side and nine feet along the lower. In addition to having a slope of four feet in twenty- two thus created, the bottom of each chamber is V-shaped, so that sand collected can easily be expelled by sluicing through the gate at the lower end of the chamber. A flume passing along the upper side makes it possible to deliver the water into any one of the five chambers, from which it can pass on from one compartment to the other through wide crested weirs, until it finally reaches the pipe line. The large cross section occupied by the water while passing through the sand box reduces its velocity so that silt carried in suspension will be deposited before it reaches the pipe line.

There were originally five tunnels constructed on the line of No. 2 power plant. These are of the following lengths: Tunnel No. I, 400 feet; tunnel No. 2, 450 feet; tunnel No. 3, 450 feet; tunnel No. 4, 570 feet; tunnel No. 5, 140 feet.

Concrete pipes, the same as laid in the trench, are laid through all the tunnels. Since the construction of the plant another tunnel, located between tunnels Nos. 3 and 4, has been added. This takes the place of flume No. 18, which was slightly damaged in a storm, thus deeming it advisable to drive a tunnel behind the canyon spanned by this flume. The length of this new tunnel is 173 feet.

|

| Generator and High Tension Switchboards in Santa Ana Power Plant No. 1 |

At the end of the gravity conduit a forebay, twenty feet by seventeen feet, inside measurement, and from five to ten feet deep, has been constructed of concrete masonry. The purpose of this is two-fold, namely, to allow the water to settle before entering the pressure pipe, so that silt which may have been washed into the conduit, through possible breaks, will be deposited, and so created a penstock for submerging the inlet of the pressure pipe. The very decided slope of the forebay bottom renders it extremely easy to expel accumulated sediment through the waste gate placed in the lowest corner of the structure.

|

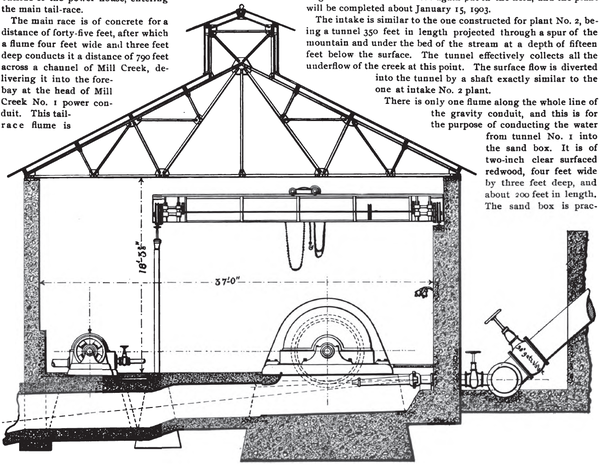

| End Section of Santa Ana Power House No. 1 |

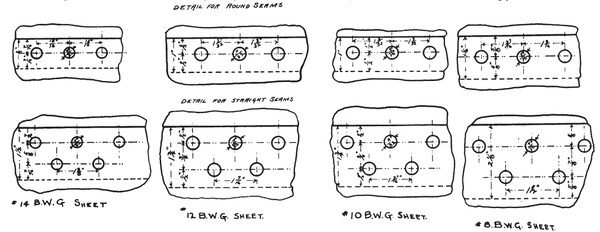

The length of pressure pipe from forebay to power house is 1411 feet, giving a fall of 627 feet between the two points. This pipe is eighteen inches inside diameter, and is manufactured from steel plate, No. 14 to No. o, B. W. G. The pipe is made with double-riveted longitudinal seams and single-riveted round seams. It is double-dipped in asphaltum to preserve it against rusting. The whole line is laid in a trench from three to six feet deep, and carefully back-filled with earth and rock.

Heavy anchors of concrete are placed, extending all around the pipe, at five different points on the line. These are dovetailed into the solid rock in the sides and bottom of the pipe trench, and will prevent movement of the pipe line under all possible conditions. At the end of the main pressure pipe there is a large cast steel Y, by means of which the line is branched into three pipes, two of which are thirteen inches in diameter and conduct water to the two generators operated from this pipe line, while the third is six inches in diameter, being used for supplying water to the two exciters. Since the curves made in branching the pipe are all of long radius, there are no losses of head due to elbows and angles. The pipe line is well equipped with blow-offs, air valves and pressure gauges. There is also a stand-pipe for the escape of air bubbles located at a point twenty feet lower than the forebay, an air chamber for counteracting water hammer, located near the power house, and two eighteen-inch gate valves, one at each end of the main pipe line. The factor of safety for everything entering into the construction of the pipe line ranges from five to six, and its operation for more than two and one-half years has shown it to be perfect in every respect.

For the overflow of the forebay a waste flume, constructed of two-inch clear surfaced redwood, and 1200 feet in length, extends down the slope of the mountain to Mill Creek. This waste flume is for carrying any portion, or all, of the water flowing in the gravity conduit back to Mill Creek stream when it is not passing through the pressure pipe. It has a capacity sufficient to carry all of the water flowing in the gravity conduit, and it is securely anchored to the bedrock and soil of the mountain.

The water, after passing through the water wheels, or when deflected from there, passes out through a tunnel from each wheel pit, and below the power house floor. In these tunnels, and immediately beyond the line of the generators, are placed upper and lower curved deflector plates. The stream, when either partly or wholly deflected, strikes the upper plate, which is anchored in the arch of the tail-race tunnel, and is turned down, striking the other plate in the tunnel floor. The curve of the lower plate is such as to again direct the water along the floor of the tail-race, in which manner it passes for a distance of thirty feet beyond the outside of the power house, entering the main tail-race.

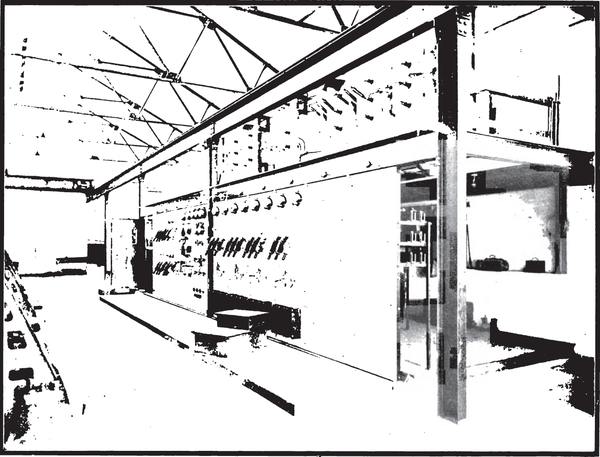

The main race is of concrete for a distance of forty-five feet, after which a flume four feet wide and three feet deep conducts it a distance of 790 feet across a channel of Mill Creek, delivering it into the fore-bay at the head of Mill Creek No. 1 power conduit. This tail-race flume is constructed of clear redwood, from one and one-half to two inches in thickness, on a trestle work from four to sixteen feet in height. The arrangement of the tail-races has proven entirely satisfactory. When the stream is wholly deflected the force of the jet is completely neutralized by the two deflectors, causing the water to pass through the portion of the tail-races beyond at an ordinary velocity. The wear of the plates up to the present time has been very slight; but should it ever become necessary, they can readily be replaced by new ones, since they are bolted down on the concrete and not embedded in it.

The power house, which was thirty-seven and one-half by forty feet, is built entirely of concrete masonry and steel, and is equipped with a fifteen-ton traveling crane. The walls and floor of the building are of concrete and the roof is a steel truss of flat and angle bars covered with galvanized corrugated iron.

The designs and superintendence of construction for the above were by F. C. Finkle, during 1898 and 1899, as chief engineer of the Redlands Electric Light and Power Company, which built the plant. The water wheels were designed by the Pelton Water Wheel Company, and the electrical equipment by the General Electric Company, but were installed under the superintendence of H. H. Sinclair, president, and F. C. Finkle, chief engineer, of the Redlands Electric Light and Power Company.

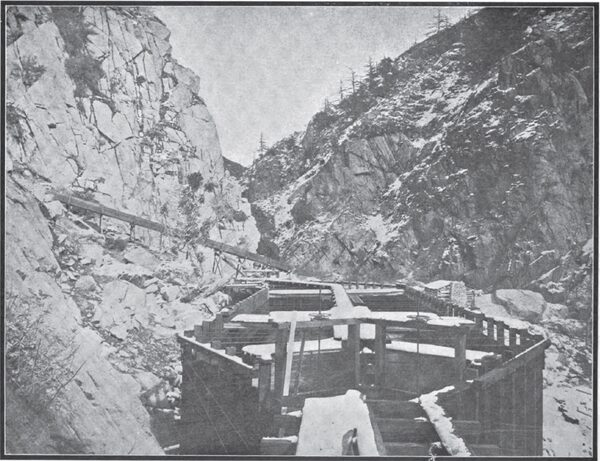

THE HYDRAULIC FEATURES OF MILL CREEK NO. 3 PLANT.

There was one mouth's active construction on this power plant during July, 1899. After this and until July 1, 1901, work was carried on with a small force driving tunnels. On July 1, 1901, a large construction force was again put in the field, and the plant will be completed about January 15, 1903.

|

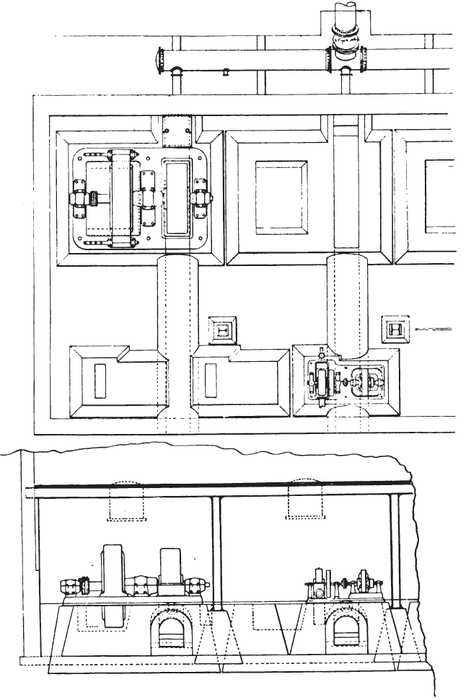

| Plan and Elevation of A Generator Section of Santa Ana Plant No. 1 |

The intake is similar to the one constructed for plant No. 2, being a tunnel 350 feet in length projected through a spur of the mountain and under the bed of the stream at a depth of fifteen feet below the surface. The tunnel effectively collects all the underflow of the creek at this point. The surface flow is diverted into the tunnel by a shaft exactly similar to the one at intake No. 2 plant.

| |||

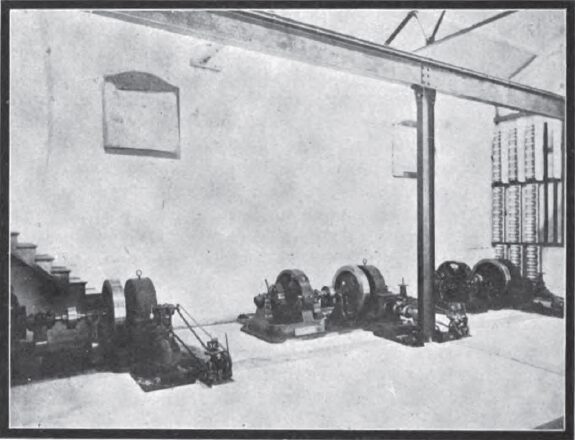

| The Exciter Section Santa Ana Plant No. 1 |

There is only one flume along the whole line of the gravity conduit, and this is for the purpose of conducting the water from tunnel No. I into the sand box. It is of two-inch clear surfaced redwood, four feet wide by three feet deep, and about 200 feet in length. The sand box is practically 100 feet long by fifty feet wide, and built according to the plan of sand box for plant No. 2, with the following exceptions: There are eight chambers twelve and one-half feet wide by fifty feet long; the slope in each of these towards the gate is four feet in fifty, and all of the dividing walls between the chambers is three feet below the water surface in the sand box, except the middle wall, which is higher than the water surface, and allows the water to pass through a gate instead of over the wall.

| |||

| The Transformer Section Santa Ana Plant No. 1 |

While the precautions which have been taken to clear the water which will be applied to the water wheels of Mill Creek plant No. 3 are unusually thorough, it should be remembered that the high head at which these wheels operate make it necessary that the water should be as free from grit and sediment as is possible.

There are five places along the line of the gravity conduit requiring inverted siphons. These are described as follows:

|

These siphons are equipped with blow-offs, air valves and bell-month taper inlets. The profile of the line gives such au hydraulic head on each siphon as to make the carrying capacity of each twenty second-feet of water, regardless of the fact that they vary in diameter. All the siphon pipes are laid in covered trenches, with the top of pipe three feet below surface of ground. There will be about 25,000 lineal feet of concrete pipe of thirty-one inches inside diameter. The shell of this pipe is three inches thick. It is made of wash sand and gravel, screened through two-and-one-half-inch mesh, two and one-half parts, to Portland cement one part, by measure. The mortar is well mixed, sprinkled to make it wet, and tamped in forms such as are ordinarily used for making cement pipe. The pipe is made in two-foot sections and laid with heavy cement collars outside for joints, and plastered smoothly inside. The trench is back-filled to cover the pipe at least three feet everywhere. The pipe is laid through all of the tunnels, as well as along the open country between them, except where siphons are constructed. The grade of the gravity conduit is two-tenths of a foot per 100 feet, which will give a carrying capacity of twenty cubic feet per second.

There are nineteen tunnels on line of power plant No. 3 in Mill Creek. They are excavated four feet wide by six feet high in the clear. The length of each of these tunnels is given in the following table:

|

At the end of the gravity conduit is located a forebay sufficient to hold ten second-feet of water, continuous flow, for six hours. The purpose of this structure is to store the surplus water at times when the load on the plant is light and make it available on the peak load, extending over about six hours each day. The forebay is constructed by throwing an earthen dam twenty feet long on the bottom, 166 feet long on the top, and thirty feet high across a ravine at the head of the pressure pipe. The dam is rendered impervious by paving its up-stream slope with cement, and all weak places in the bottom and sides of the reservoir will also be similarly paved. The great value of this storage in connection with No. 3 power plant can readily be seen when we remember that ten second-feet, for six hours, through power plant No. 3, means 1500 actual electrical horsepower during that time, and 400 such horsepower more through the company's No. 1 plant, through which the water will also pass after leaving No. 3 plant.

|

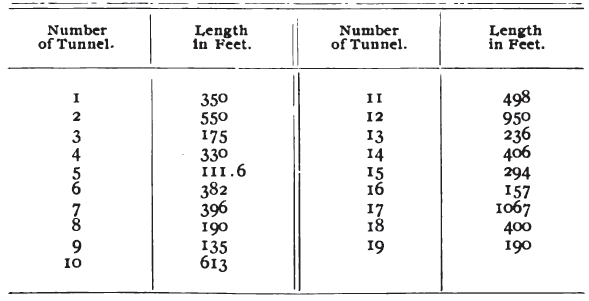

| Transformer Lifting Device Santa Ana Plant No. 1 |

The pipe line from the forebay to power house No. 3 is 8490 feet long and has a fall of 1960 feet from the water level in forebay to power house floor. The main Hue consists of 2485 feet twenty-six-inch pipe, 2150 feet twenty-four-inch riveted pipe, and 3450 feet twenty-four-inch lap-welded, with eighty-two feet eighteen-inch and 233 feet fourteen-inch pipe for branch lines to the four different units. All twenty-four-inch and twenty-six-inch pipe is continuous riveted pipe, varying in thickness from No. 14 to 0000, B. W. G., and all other twenty-four-inch pipe is lap-welded from seven-sixteenths to seven-eights inches in thickness. The eighteen and fourteen-inch branch pipes are also lap-welded of five-eights and one-half-inch metal, respectively. The material used for all these pipes is open-hearth, box-annealed steel, of 40,000 to 60,000 pounds per square inch tensile strength. All joints, except those used in laying the eighteen and fourteen-inch branches, are riveted; the latter are made with solid welded steel flanges. The branching of main pipe lines is done by means of cast steel Ys and curves having radii from nine to twelve feet. All flanges on these specials are also of cast steel. The line is fully equipped with air valves, blow-offs and pressure alleviators, which make accidents caused by the formation of a vacuum or by the presence of water hammers impossible of occurrence.

|

| Arrangement of Transformers and High Tension Wiring, Santa Ana Plant No. 1 |

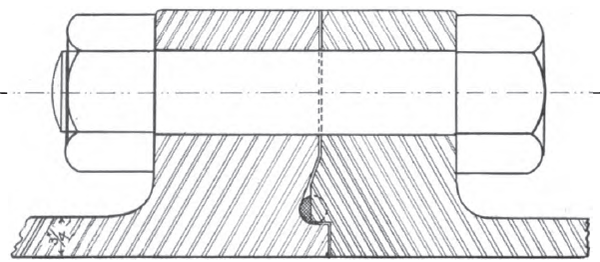

The joints used in laying the force main of the pipe line of Mill Creek plant No. 3 were made in the following manner: On riveted pipes all joints are made by means of a single row of rivets, such joints being in what is known as "round seams." The details for this riveting are shown by the sketch on page 39. The description of the work is as follows. The holes are punched with a multiple punching machine in a manner to make them all meet fairly when the sections of pipe are pulled together. The joint is then riveted, cold rivets being used on all gages lighter than No. 8 B. W. G. and hot rivets for all heavier gages. After the seams are riveted the pipe is chipped and caulked to make a perfect union, metal to metal, entirely around the circle of the joint. Where the lap in the joint occurs the metal of the overlapping sheet is also chipped and caulked in the same manner. After this is done the inside ^and outside are painted with asphaltum to protect the pipe against the action of water and soils.

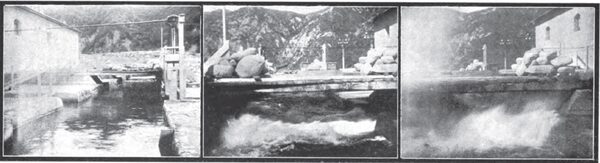

| |||

| A Study of the Santa Ana Tail Race, Showing, in the Last Two Views, Full Load and No Load Discharges Respectively |

The joints on lap-welded pipes fire made in two different ways. On the lighter pipes what is known as the "expanded" or "bump" joint is employed. One end of the pipe section is swelled sufficiently to permit the other to enter it. Holes are punched through both thicknesses of metal where the insertion of one pipe into another is made and the riveting is done by means of hot rivets in the same manner as shown for round seams for riveting pipes in the drawing herewith. The joint is also chipped and caulked in the same manner as on riveted pipe. For the lighter gages of lap-welded, expanded-joint pipe one row of rivets is employed in making the joint, but for metal having a thickness of from five-eighths to three-fourths of an inch, two rows are used, and the rivets staggered in the same manner as when making straight seams on riveted pipe. The diameter of rivets used for these heavier pipes is seven-eighths of an inch. A portion of the lap-welded pipe is made with solid welded steel flanges. The joint employed in laying these pipes is also shown in the sketch which applies to the lap-welded pipe with shell three-fourths of an inch in thickness. The principle of this joint is that a groove runs entirely around the flange, as shown in the separate drawing, into which is squeezed a five-eighths-inch circular rubber gasket. This gasket is made in the form of a circle and not of the exact diameter of the groove in the flange. It is inserted into this groove and pressed into the space shown when the flanges are drawn together so as to have their faces come metal to metal. The principle of this joint is excellent, since the possible escape of water from the interior of the pipe, and the pressure against the rubber gasket which may be due to it, simply tend to press the gasket more firmly into the recess in the flange, thereby making an absolute guarantee against leaks. There is no chance for this gasket blowing out, since the flanges are drawn up by means of the bolts so as to have the two metal faces in perfect contact.

SANTA ANA POWER HOUSE NO. 1.

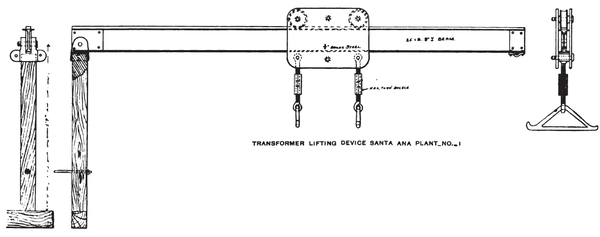

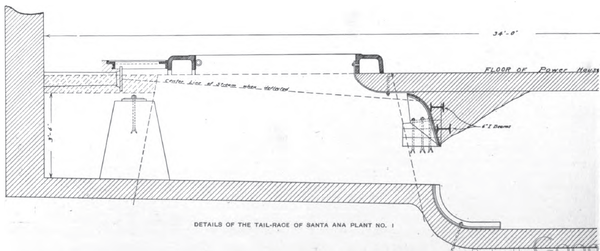

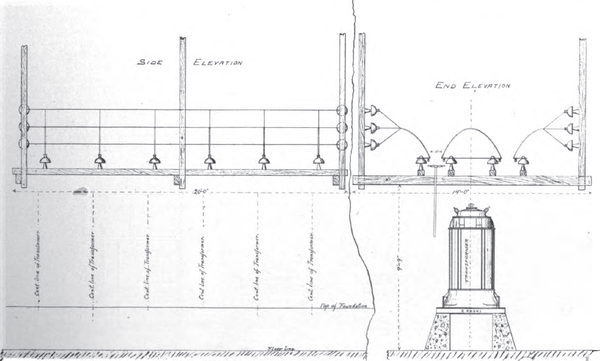

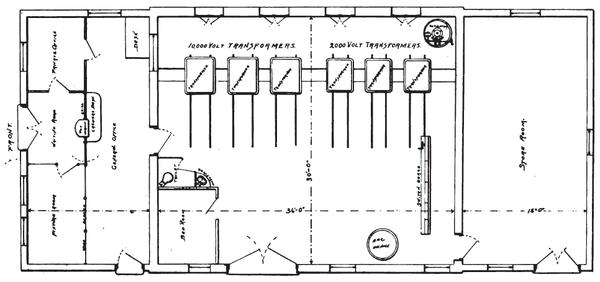

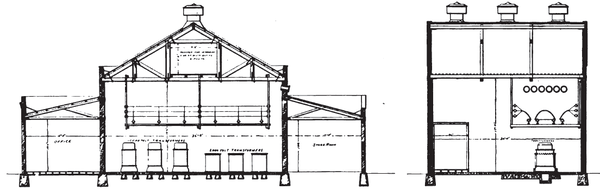

A substantial concrete building, having an inside length of 127 feet and being thirty-six feet in width, houses the machinery that constitutes the plant known as Santa Ana Station No. 1. The building is, in fact, one single piece of monolithic concrete, and no iron is used in its construction except that necessary to support the crane and steel roof. This crane spans twenty-seven feet of the building, one side being supported on the wall nearest the water wheels, and the other side being supported by iron columns practically in line with the switchboard Each generator, with its Pelton water wheel, is mounted on a base plate having three common bearings, and the four generators and water wheel sets which constitute the plant are arranged with shafts parallel to the long way of the building. The water is directed upon the wheels by means of a deflecting nozzle which leaves the receiver at right angles, and when the stream is deflected from the wheel it is projected through a tunnel beneath the floor of the power house and outside the building through a covered duct. The latter part is lined with boiler plate to a point about seventy-five feet from the wheel, where these separate ducts are united to a common canal twelve feet wide and ten feet deep. The accompanying illustrations and drawings give the details of this very interesting piece of construction, which it is confidently believed is the peer of any similar work to be found elsewhere. The water in the transverse section of the tail-race is kept at such a height that it is just awash with the wheel-pit linings, or practically three feet below the buckets of the wheels. This results in a cushioning effect, which quiets the jet when the nozzle is deflected. So far as known, this arrangement is the first of its kind ever applied to wheels of the Pelton type, and by means of it each individual wheel and its wheel pit are easily accessible without interference from the discharge water from the other wheels, and as a result the arrangement permits the exercise of diligence in the maintenance and inspection of that part of the hydraulic plant.

|

| Details of the Tail-Race of Santa Ana Plant No. 1 |

Each generator and wheel are, as stated, mounted upon a common cast iron base with three bearings. The generators are of the revolving field type, running at 300 revolutions per minute, and being each of a capacity of 750 kilowatts. They are wound with a bar winding for 750 volts, and the armature is three-phase Y connected, delivering current at fifty cycles. The plant at present contains four such units, with foundations for four more similar units, to be installed when the second pressure pipe is put in. The exciter units are three in number, each having a capacity of thirty kilowatts at 175 volts, and are direct connected to suitable Pelton wheels.* (*Described in detail in THE JOURNAL, Volume XI, page 31, January, 1901.) The generator wheels are governed by Type F Lombard governors, which operate to deflect the nozzle, and are actuated by water at a head of approximately 120 feet, supplied by an independent reservoir. This is in turn furnished by water taken from the main pipe line. These governors were the first of the type named that were ever manufactured, and the entire plant and system was constructed with the idea of maintaining water wheel regulation of the highest possible degree of perfection. In this the expectations of the company's engineers have been fully realized, for they contend that better governing has been obtained in the hydraulic plant of the Santa Ana station than it is possible to secure with a steam plant, unless it be in the use of steam turbines. The exciters are governed by small mechanical sectroidal governors. The water wheel and exciter governors were furnished by the Pelton Water Wheel Company, as was also the receiver, together with its connections and valves. The generators were furnished by the General Electric Company.

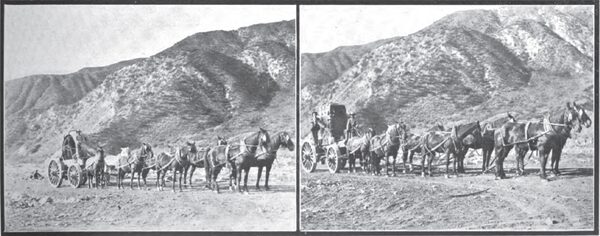

| |||

| A View in Mill Creek Canyon |

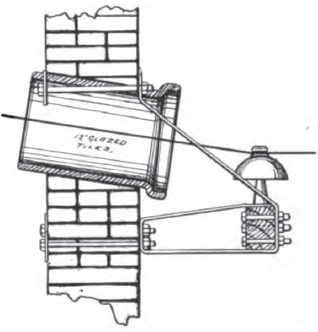

The generator switchboard is a simple arrangement, with double busbars, having a separate panel for each generator, and total output panel, with suitable recording and integrating instruments, and two transformer panels, each containing two sets of transformer switches. All of the switches are of the quick-break knife type and have been perfectly satisfactory. The exciter panels are also in duplicate. All low tension wiring is of 700,000 circular mils, cable, which is carried from the transformer switches to the transformers through an air duct which runs beneath the floor. The twelve 2so-kilowatt transformers used are all of the air-blast type and are carried on I beams, each group of three being placed in a row across the transformer pit, which is of sufficient depth to allow a man to get underneath the transformers should it be necessary. Through these transformers the generator potential of 750 volts is stepped up to 33,000 volts in Y-connection, the neutral point being grounded at the station.

As is clearly shown in the illustration on page 24, the high potential board is mounted in a gallery over and slightly to the rear of the generator board, and it consists of a transformer panel for each three-phase group of transformers, two line panels, and one connecting panel, which consists of a double busbar arrangement with double throw switches. By means of these switches the connecting panel may be divided in half, making it possible to operate on either of the two transmission lines on one-half of the bank of transformers, so that either half of the high-tension board may be rendered dead for repairs or cleaning. This high-tension board is half-way between the inner rail of the crane and the wall of the building, facing the tail-race, while the trans-formers are in line with the space back of the low-tension board on one side and the exciters on the other. All high-tension apparatus is protected by General Electric short-gap lightning arresters having forty-eight gaps to each leg, and the arresters are so adjusted that an arc will hold at about 42,000 volts for a fraction of a minute without injury to the arrester equipment or impairing its usefulness. The highest operating voltage is 34,700.

The Santa Ana station has been in absolutely continuous operation since January 22, 1898 and there is yet to occur the first shut-down of one moment's duration due to the failure of any part of the canal line, power house or its equipment, and, as far as the machinery of the power house is concerned, there have been no repairs except of a very minor nature, such as renewing a small valve or a small pipe here and there, and other repairs to worn-out nozzle tips and a few buckets for the exciter wheels. Not a single bucket for the large wheels has been changed or altered in any way during the entire period.

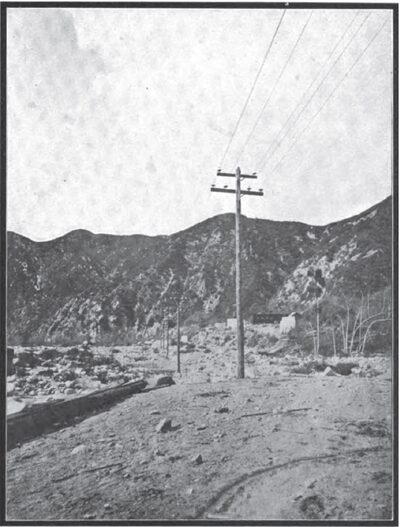

THE 33,000-VOLT TRANSMISSION LINE.