[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. XIX, no. 365, p. 404, col. 1-2

THE GENERAL ELECTRIC COMPANY'S PORCELAIN FACTORY AT SCHENECTADY, N. Y.

One of the interesting features of the growth of a great manufacturing concern is the manner in which varied and widely differing industries are included as the progress of development advances. A striking example of this evolution is furnished by the very complete factory for the manufacture of porcelain for electrical purposes, which the General Electric Company has established as an integral part of its immense establishment at Schenectady.

An especially perfect porcelain of hard, white, vitreous character, dense in structure, non-absorbent and unaffected by acids, alkalis or gases was demanded, and unavailing efforts were, it is said, made to obtain such porcelain outside. Confronted with this difficulty the company decided to build its own porcelain factory. This has now been in operation for the last three years with excellent results. It comprises mixing, moulding, drying rooms and kilns, and stands a few yards away from the eastern division of the Works, between Kruesi Avenue and the N. Y. Central Railway. It is equipped with the latest and most approved machinery, and is operated by a corps of skillful workmen under the careful supervision of an experienced man. Although only on a miniature scale, it is a complete pottery.

The building is a two-story brick structure covering a space of about 14,000 square feet. Through the roof protrude the squat chimneys of the kilns which are kept in continuous service with the constant rush orders.

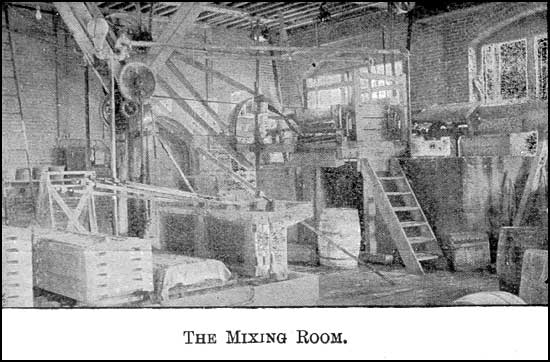

Entering by the main door admission is immediately had to the mixing room where the crude kaolin or china clay which is the best for the purpose that the market can supply, is brought to be washed, manipulated and mixed. Passing from the mixing machine the clay is strained through bags to remove any material of a hard nature which might interfere with future operations. It comes from the straining press in large lumps and in that condition is partly dried, placed in a pulverizer and reduced to the necessary condition for transmission to the press room, which it reaches in the shape of a moist greyish, disintegrated clay.

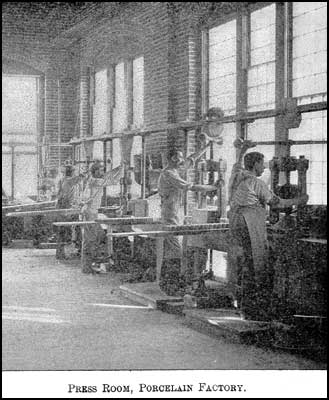

The press room is immediately over the mixing room, and is well lighted and ventilated by large windows on three sides. The upright screw presses in which the porcelain is moulded stand along the three sides of the room directly under the windows. It is here that porcelain of the most intricate shapes and fashions is turned out to meet special orders. The moulds which are of special tool steel, are made in the works by a corps of efficient tool makers. Before cutting these moulds, or dies, the shrinkage of the porcelain in drying and baking is so nicely calculated that, when the porcelain in its finished state leaves the kilns, the metal parts have been stamped out in the punch press house a few yards away fit accurately. The catalogue number of the porcelain appliance is cut in the die, and this appears in relief on the base of the finished device.

The lower part of the die is fixed to a small table, which can be moved up or down by means of a foot lever, and is set in a hollow space in the larger table forming the base of the press. The upper part of the mould is fitted to a sliding bar which is elevated and depressed by the lever and screw. The die being fixed in position, the pressman takes a portion of the pulverized clay and weighs the proper quantity in a pair of scales. With a small brush the two dies are then thoroughly dampened, the lower mould is lowered to its normal position and the operator pours in the clay which he presses evenly down with his hands to give it a preliminary packing. A vigorous twist is given to the lever and the upper die is brought down upon the clay with considerable pressure, which is increased by an additional pull at the lever. Another twist in the reverse direction, and the upper mould rises, the lower one being elevated by the foot lever at the same time. Depression of the latter lowers the lower die, and leaves the mass of clay which has assumed the form desired in the hands of the workman. The clay is then laid upon a rack to be air dried. The drying racks which occupy the entire space in the centre of the press room as well as a part of the second floor of the main building, are always full, for the press room is taxed to the utmost to keep up with the orders.

A door in the press room opens into a spacious room which occupies part of the second floor of the left wing and the whole of the main building. In this room all the pieces are corrected before they are sent to the kilns. The burrs are removed from all the holes through which screws or punchings are to pass, the marks of the dies are cut off, and the pieces put into final condition for baking. Through this room pass the upper parts of the kilns.

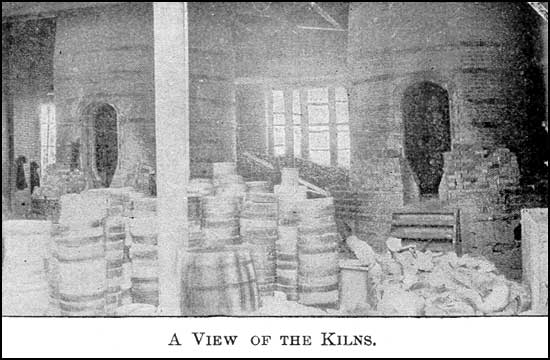

Descending from this clay finishing room the kiln room on the ground floor is reached. Around the four pottery kilns stand piles of yellow "hillers" and "saggers" which are made in one corner of the kiln room. Into these clay pots or pans the moulded pieces are placed. When full a cover is placed over each, and hermetically sealed. The kiln is then filled and the doors closed.

After the first baking the porcelain comes out in the form of a hard, white, compact biscuit. For certain insulating purposes, this biscuit is employed as it comes from the kilns. It is non-absorbent to a high degree, and is used for socket bases and other purposes where the porcelain is not exposed. For switch bases, insulators, cut-outs, etc., the porcelain is, however, glazed, and subjected to another firing. When it leaves the firing kiln it is as nearly perfect as the potters art can make it; beautifully white, compact in texture, extremely hard, impermeable to moisture and having exceedingly high insulating properties.

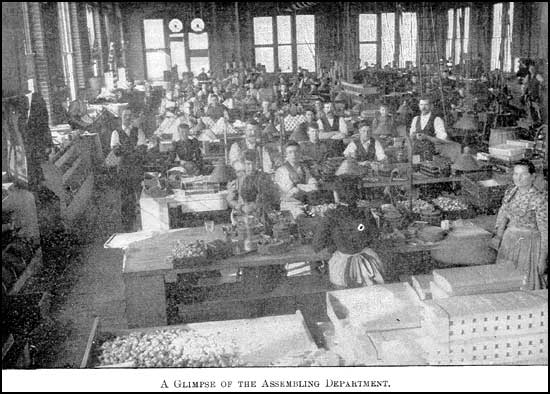

From the kilns the porcelain which is to be used in cut-outs, switches, sockets, transformer connecting boards, and in many other appliances, is taken to the second story of the right wing of the building, where the brass punchings are applied to the cut-out, the screw shells fastened to the connections, the screws set and the insulating composition applied where needed. In another part of the room are made the thousands of key and keyless sockets with porcelain bases and polished brass shells, and millions of glass fuse plugs for the plug cut-outs. At the table where the plugs are made a striking feature are the electric soldering devices, used to solder the fuse metal to the tip and exterior screw shell of the plug.

The assembling of ratchet snap switches occupies a little department by itself, as does the manufacture of the copper terminal fuses for link cut-outs. In sundry other portions of the large room other porcelain appliances of varied character are made ready.

The finished appliances are then passed on to the next room where, each neatly wrapped in tissue paper, they are packed in brown card boxes, bearing a label showing their source and giving their description.

The insulators for special work such as for transmission at very high voltages are tested in a small room adjoining. Among these may be mentioned the large double petticoat insulators for the important power transmission plant at Folsom-Sacramento. Each insulator is subjected to as severe a test as could be devised, and before being accepted as satisfactory must show its capability of withstanding a pressure of 25,000 volts alternating. In order to test the endurance of these insulators, the testing current was raised as high as 52,000 volts before any of those subjected to the test gave away.

The only trace of the enormous pressure on the outside of the insulator was a pin point hole scarcely perceptible. The General Electric Company, was one of the pioneers in the use of porcelain as the most convenient and satisfactory insulating material. Gradually electrical manufacturers came to recognize the merits of porcelain, as the electrical consumer had done already, and porcelain has come into much more general use, until to-day it is used almost universally for insulation purposes.

|

|

|

|