[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 21, no. 24, p. 327-328, col. 1-3,1-2

Electrical Equipment of the South Side

Elevated Railroad.

About the middle of July last the work of changing the South Side elevated railroad of Chicago, better known as the Alley "L," from steam to an electric road was started, and has been progressing quietly but none the less vigorously since that time.

The outside electrical construction is now so near completion that the Western Electrician is enabled to publish herewith several photographic views and a synopsis of the work and the methods employed in its execution.

The object of the engineers, Messrs. Sargent and Lundy, seems to have been to employ standard methods and material where-ever possible, and so far as the construction work is concerned this determination, has proved to be wise.

One hardly appreciates at first glance what it has meant to the railroad company, the contractors or the engineers to do the work above mentioned without accident or interruption to the very frequent train service of an elevated railroad.

The outside electrical construction naturally falls into three main divisions: first, track bonding and return circuit; second, third or trolley rail; third, feeder system.

For the return circuit the tour service rails and the entire steel structure of the road is used, being made common by a system of bonding and cross-bonding and connections between the rails and longitudinal girders. Standard No. 0000 copper bonds are used at each rail joint, the track being cross-bonded at frequent intervals, and these cross-bonds in turn connected with the structure at still greater intervals. This work necessitated the drilling in the service track rails and structure about 20,000 seven-eighth inch holes, and the placing of 10,000 rail and other copper bonds. Owing to the presence of the wooden guard-rail on either side of the track rail the drilling of this great number of holes in anything like an economical manner was for a time a perplexing question. With the use of an electric motor, a flexible shaft and a compact little drill press which operated in nine inches of space, the work was easily and rapidly carried on. A good idea of the appearance of the apparatus will be had by reference to Fig. 1.

The two drilling outfits were designed and built especially for this work by the Electrical Installation company of Chicago, and caused much favorable comment by all who witnessed their operation, except candidates for jobs working hand ratchet drills. During certain hours of the day, when a stretch of track between two cross-overs could be had, these little wagons were run along on the guard-rails, their wheels being flanged and made to fit a 15-inch gauge, the distance between guard-rails. At other times, when the schedule would permit of the use of but one track, it was necessary to do the drilling between trains, sometime's on two minutes' headway.

|

| Electrical Equipment of the South Side Elevated Railroad. |

The men handling these drilling outfits became so expert in their use that the attaching and detaching of the drill presses to the rail was accomplished with a rapidity and precision that was remarkable, and reduced the time lost by the passing of trains to a minimum. Then, again, the rivalry between two drilling crews was so sharp that personal encounters were often imminent. As a precautionary measure, a red flag was always placed between the workmen and an approaching train, this flag being pulled only when the track was clear.

During the progress of the entire work on the service rails of the South Side Elevated Railroad company not a train was held over 10 seconds, and the few delays were simply due to the precaution exercised by the drillers in not allowing a train to pass when there was a possible danger to it or the workmen.

For the third or trolley rail a 60-foot 40-pound T-rail is used, which is double bonded with horse-shoe bonds and is mounted on the General Electric company's standard; third-rail insulator. A view of the contact rails in place is shown with the feeder cables in Fig. 3. A glance at the picture of the feeder system, which was taken at Michigan avenue and Fortieth street, will give a clearer idea of what it consists of than any amount of descriptive matter. It may not be amiss, however, to state the quantity of copper used and the method employed in erecting it. From the power house, which is located at State and Fortieth streets, immediately adjacent to the elevated structure, there extend southward five bare copper cables with a total sectional area of 5,500,000 circular mils, and northward from the power house three cables of a sectional area of 2,500,000 circular mils. In all there are about 24 miles of copper cable in use weighing about 200 tons, and worth, at the present market prices, about $55,000. As will be seen in Fig. 3, these cables are supported by standard cross-arms, iron cored pins and glass insulators, iron-clad insulators being used wherever additional strength is required. The cables are of three sizes, 1,500,000, 1,000,000 and 500,000 circular mils, the first being supplied in 1,000-foot lengths, the second in 1,500-foot lengths, and the third in 3,000-foot lengths, and one length to a reel, which weighed about 2 1/2 tons each.

The engineers exacted that the cable must not be cut, and permitted only as many splices or joints as there were reels of wire. Their specifications also provided that the cables be run under the structure at the 15 track cross-overs. How best to pull these heavy cables along the structure, down beneath it at cross-overs, and then back to the normal position, without injury to the cables, was somewhat of a problem; it was extremely easy of execution, however, with the aid of sheave wheels mounted in rigid wooden frames, and a locomotive to do the pulling. The stringing of all the feeder cables had to be done between the hours of 1 and 5 a. m., in order not to interfere with traffic, but the greater portion of the work was done by daylight. The day crew distributed reels at predetermined points, setting up the reel stands and sheave frames, arranging the tackle so that the night crew, with its locomotive, had simply to hook on to the end of a cable and pull it into place, the reels being always on the ground under the structure, as is shown in Fig. 2. In this manner a 3,000-foot length of 500,000 circular mils cable was pulled into place in a surprisingly short space of time. Another day crew was employed in the splicing, stretching, tying in and otherwise finishing the work. To protect the feeders from accidental contact, and serving in addition as a walk, there is built over them a wooden box, which is now being laid at the rate of about 3,000 feet a day. This covering it not shown in the picture.

For the speed and excellence of this work credit is due the Electrical Installation company, which did all of the outside construction, with the exception of laying the third rail, and which has also the sub-contract, under the Sprague Electric company, for the remodeling and equipment of the cars. The work was done under the general supervision of Superintendent J. A. Brett, with the assistance of A. H. Stocking, engineer. Walter Halpine was foreman of the outside construction, and George E. Morrine of the car equipment.

| |||

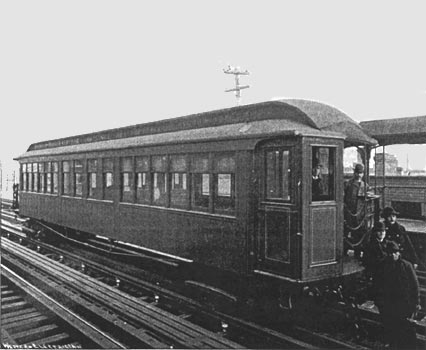

| Electrical Equipment of the South Side Elevated Railroad. — Car Fitted With the Sprague Multiple-Unit System. |

In Fig. 4 is shown one of the Alley "L" cars equipped for the Sprague electrical multiple-unit system of train propulsion, with folding vestibule. All of this company's cars will be similarly equipped, each being an independent unit, supplied with its own contact shoes, controller, motors, air compressor, engineer's air valve and gauge, electric heaters, etc. Each car may be run by itself or as a unit in a train of any number of cars. A train of these cars is now in daily service on the Metropolitan West Side road, and it seems to be giving entire satisfaction.

The power house for the Alley "L" is nearing completion, and will be completely inclosed withing two weeks.