[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 28, no. 21, p. 621-622, col. 1-2

Niagara Power Transmission Up to Date. — 1.

BY FRANK C. PERKINS.

NIAGARA POWER FOR THE BUFFALO STREET RAILWAY.

NIAGARA CATARACT electric power is delivered to the Buffalo Street Railway Company for operating the trolley cars in the City of Buffalo. The present plant has a capacity for 8000 horse-power, and this power is generated by means of nine Lake Erie vertical engines and two Ball cross-compound horizontal engines.

The present electrical equipment consists of three direct-connected generators of the to-pole type generating 800 kilowatts each at 100 revolutions. Six four-pole generators are operated by belts, generating 200 kilowatts each at 425 revolutions. The six Edison bi-polars were the first machines installed, and each furnishes 200 kilowatts at about 400 revolutions. The new equipment consists of two rotary transformers delivering 400 kilowatts each at 500 revolutions.

| |||

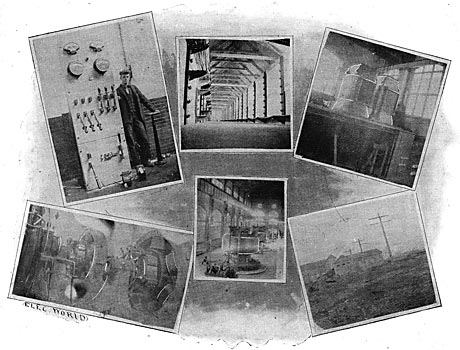

| Fig. 1 — Low Tension 3-Phase Alternating Switchboard, Buffalo Street Railway Power House. Fig. 2. — Conductor Bridge With Cables, Niagara Falls Power House. Fig. 3. — Static Transformers, 11,000 Volts, Niagara Falls. Fig. 4. — Two Rotary Transformers, Buffalo Street Railway Power House, Buffalo. Fig. 5. — Interior of Power House, Niagara Falls. Fig. 6. — Transmission Line. Transformer House in Background. |

The overhead transmission line is installed from the Falls to the city line of Buffalo. From this point the current is conducted through cable laid in underground conduits along the canal to the transformer house of the Buffalo Street Railway Company. The conduit has six ducts, and at present there are three high-tension cables laid. These three cables are each 350,000 circular mils cress section, and thoroughly insulated and tested with 80,000 volts potential. They are rubber covered and braided, and have a lead sheathing throughout.

These three cables have a capacity of 5000 horse-power at 11,000 volts and double that capacity or 10,000 horse-power at 22,000 volts. It is the intention to operate with 11,000 volts to start with, and finally it is expected that 22,000 volts will be used. Should this voltage be successful the six ducts will then hold cables capable of delivering a total of 20,000 horse-power to the power station of the Buffalo Street Railway Company.

The current is delivered to the Buffalo Street Railway Company by the Cataract Power & Conduit Company, which is to distribute the power in the City of Buffalo, having had transferred to it the franchise which was originally granted to the Niagara Power Company. The transmission line was erected by the Crosby-White Company and the conduit was furnished by the H. B. Camp Company, of Aultman, O.

The high-tension switchboard is built of blue Vermont marble and was constructed by the. General Electric Company. The three high-tension mains enter the transformer house by the canal route through the underground conduit. They are high-tension mains and are carried overhead on the walls of the transformer house. They are supported by triple petticoat porcelain insulators tested to 50,000 volts. Three Wood lightning arresters are used in the transformer house and are placed in the corner at the right on entering.

The static transformers are placed in position in the transformer house by means of a special crane erected in the building for this purpose. The low-tension cables are installed below, and the high-tension cables above, the transformers. The low-tension cables from the static transformers to the rotary transformer switchboard consist of six rubber-covered cables of 600,000 circular mils each. They are supported on porcelain insulators fastened with iron straps and all insulation is looked after as though the wires were bare. The static transformers are three in number, and each have a capacity of 354 horse-power. The efficiency of these stationary transformers is 98 per cent., and the weight is three and a half tons. The high-tension wires to the transformers are to conduct the current at first at 11,000 volts pressure and later to be increased to 22,000 volts potential. The low-tension wires will receive the current from the stationary transformers at 500 volts, and at this pressure is transformed from an alternating current to a direct current at the rotary transformers. The three static transformers are each 6 feet 9 inches high, 3 feet 6 inches square at the top and 4 feet square at the bottom.

The temperature of the transformers must not exceed 40 degrees C., and to attain this condition blowers are used to force an air draft through them. The platform of wood on which the transformers are mounted is made air-tight, except under the transformers, where the air passes up through the iron cores. Dampers are provided to control the circulation of air. A 60-inch blower is used for this work, the power being supplied by a 2-hp motor operated by a direct current of 500 volts.

The low-tension switchboard receives the current from the static transformers at 500 volts potential. Two sets of three switches each are used for closing' the circuits, to the three-phase alternating motor end of the rotary transformers. Two Thomson alternating ammeters are used to indicate the current reading up to 1000 amperes received from the rotary transformers. The field rheostats are placed under the floor, and are controlled by wheels on either side of the switchboard.

The rotary transformers were constructed by the General Electric Company, and each has a capacity of 400 kilowatts. The speed of these machines is 500 revolutions per minute. They are of the six-pole type, and receive the three-phase alternating current at 500 volts, transforming it to direct current of 500 volts. They are compound wound, have automatic bearings and six sets of carbon brushes on the direct-current side and three sets of copper brushes on three ring collectors of the three-phase motor end. The rotary transformers are started by means of the direct-current of 500 volts, the special starting resistance being placed below the floor. The direct-current side is used as a motor on starting and when up to speed, the three-phase current is thrown on and the direct current is switched off.

The low-tension cables carrying the 500-volt direct current to the feeder switchboard are four in number. Each cable has 750,000 circular mils cross-section and consists of stranded copper wire with rubber insulation and braided, and is mounted on porcelain insulators. These cables may be switched in multiple with any set of feeder circuits in the City of Buffalo or in multiple with any of the generators in the power house.

At present there are three; generators installed and in operation. Each machine has a capacity of 5000 horse-power at 2000 volts potential. The speed of these machines is 250 revolutions per minute. They generate a two-phase alternating current which is transformed into a three-phase alternating current by static transformers in the white stone building across the conductor bridge.

Seven more generators of 5000 horse-power, each at the same potential, are now being prepared. Two exciters of 300 horse-power each are also being made. The exciters will generate a direct current at 250 volts potential and will excite the fields of the large machines.

The present large generators have their fields excited by a "Kodak" direct-connected generator plant at the water-works. This machine is a 250-volt multipolar direct-current machine.

Three railway rotary transformers are installed in the power house near the entrance. Each has a capacity of 650 horse-power and receives alternating two-phase current from the generators at 2000 volts, delivering the current to the Buffalo & Niagara Falls Street Railway Company, Whirlpool Rapids line and the Main Street line in Niagara Falls at 575 volts to 600 volts direct current, the cars on all these lines being operated by Niagara current. These rotary transformers are of the six-pole type and operate at a speed of 420 revolutions per minute. Two of these are of Westinghouse construction and the third was built by the General Electric Company. Each machine has its own switchboard.

The static step-up transformers in the transformer house of the Niagara Falls Power Company are installed above the ground, a space being left so that air may be circulated through the transformers for the purpose of keeping them cool. Each transformer has a capacity of 1250 horse-power, and the efficiency of the same is very high, being over 98 per cent.