[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 28, no. 25, p. 749-752, col. 1-2

Niagara Power Transmission Up to Date.V.

BY FRANK C. PERKINS.

CURRENT DISTRIBUTION FROM POWER HOUSE.

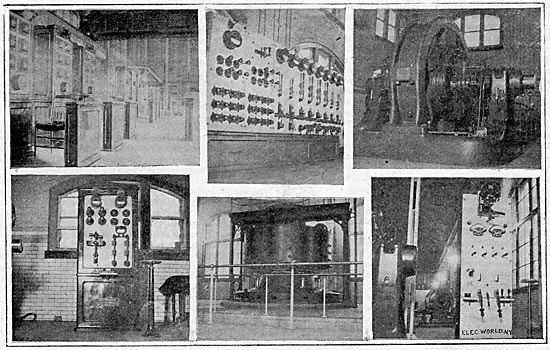

THE Niagara current as it now leaves the power house is transmitted at three different voltages and three different forms of current. The distribution thus necessitates the use of different kinds of apparatus, different switchboards and different types of measuring instruments.

1. A part of the energy leaves the power house as a two-phase alternating current of 2200 volts difference of potential direct from the large 5000-hp generator seen in the illustration, and is distributed to the consumers on the Niagara Falls Power Company's lands through the conductor bridge and subway. These consumers make such transformation as they think best adapted for their work.

2. A part of the energy leaves the power house as a direct current of 500 volts potential and as such is conducted to the feeder Wires of the Buffalo & Niagara Falls Electric Road and the Niagara Falls Electric Street Railway.

3. A part of the energy leaves the power house as a three-phase current at a potential of 11,000 volts and is transmitted by an overhead pole line to Buffalo.

That part of the power which leaves the power house as a direct current at 500 volts for use on the Niagara Falls Electric Railway lines is transformed from a two-phase current at 2200 volts to a direct current of 500 volts by means of static and rotary transformers located in the main power house building at the left near the entrance. The alternating current at 2200 volts is first reduced in voltage by the static transformers, then conducted through the switchboards seen in illustration to rotary transformers and again to the direct-current switchboard to the boo-volt direct-current street railway feeders.

One General Electric rotary transformershown in cutis used in this transformation, and two Westinghouse rotary transformers each of 500-kw capacity are also used for this purpose, making a total of 1500 kilowatts at hand for use on 500-volt circuits. The 500-kw Westinghouse rotary transformer was illustrated in THE ELECTRICAL WORLD of Nov. 21.

The 500-volt direct-current switchboard seen in one of the accompanying views is located at the extreme end of the power house and controls the current supplied for stationary motors, heating the power house, pump motor, commercial motors and feeders of the electric railways.

That part of the energy which leaves the building as a three-phase current at 11,000 volts potential difference, for the Niagara-Buffalo transmission line is transformed from a two-phase current at 2200 volts to a three-phase current, and at the same time raised in potential to 11,000 volts. In order to make the transmission as economical as possible it will be necessary to raise the voltage to 22,000 volts, and this will undoubtedly be done as soon as it is deemed safe to do so and the insulation can be made sufficiently reliable. The two-phase current for this transmission, is generated by generator No. 1 (seen in illustration), and is conducted through the subway and conductor bridge (shown in THE ELECTRICAL WORLD, Nov. 2, and Dec. 5) to the transformer house where the 1250-hp static transformers are located. The 2200-volt two-phase alternating current to these static transformers is controlled by the switches mounted on the standards shown in illustration of the raised platform in the main power house. The three-phase 11,000-volt alternating current to the transmission line is controlled from switchboards in the transformer house (illustrated in THE ELECTRICAL WORLD, Dec. 5) across the intake canal.

| |||

| Fig. 1. Instruments and Controllers for 2200-Volt 5000- HP Generators. Fig. 2. 500-Volt Switchboard for Controlling Westinghouse Rotary Transformers. Fig. 3. 500-Volt Direct Current Switchboard for Street Railways and Stationary Motors. Fig. 4. Generator for Buffalo-Niagara Transmission. Fig. 5. G. E. Rotary Transformers in Niagara Falls Power House. Direct Current for Street Railways. Fig. 6. 500-Volt Switchboard for Controlling G. E. Rotary Transformer. |

That part of the energy which leaves the building as a two-phase alternating current at 2200 volts for use on the power company's lands is conducted through the subway directly from the large generator without any change whatever in phase of current or voltage. The current from the large generators is conducted to the subway and to the switches, controllers and measuring instruments on the platform shown in the illustration, the connection being made under the floor of the platform; the doors opening into which are kept closed and locked. Danger signs are placed in view to warn employees of the high-tension current.

The various switches and meters seen upon the platform in the illustration control and measure the current consumed by the various users on the power company's, lands. The Buffalo & Niagara Falls electric light station is supplied with loop horse-power from this platform, using the 2200-volt two-phase current, which is conducted directly to the lighting station.

The Carborundum Works use Niagara power to the extent of about 1200 horse-power, transforming from 2000 volts to a low voltage.

On the same feeder wire the Carbide Works receive current for manufacturing carbide of calcium.

The Carbide Works use about 1200 horse-power at 2000 volts direct from the generators with such transformation as is necessary in the works.

The above-mentioned consumers receive their current through cables la d in the subway and are all lead-covered cables. They all have their energy controlled from the switches located upon the raised platform shown in one of the illustrations.

Several new manufacturing plants are about to be constructed using large amounts of electric power, the same to be supplied by the machines now being installed.

Beginning with the city lighting stations the following data may be of interest:

THE BUFFALO & NIAGARA FALLS ELECTRIC LIGHT & POWER COMPANY.

The current for the lighting of the City of Niagara Falls is supplied by the Buffalo & Niagara Falls Electric Light & Power Company, furnishing both arc and incandescent lights. The steam plant consisted of a Reynolds-Corliss engine, 22 by 48, developing about 260 horse-power at 95 revolutions per minute. A Rice automatic engine took care of the day load for light and small power, developing about 100 horse-power at 125 pounds steam pressure.

The electric lighting equipment consisted of Brush arc light machines and Westinghouse alternators for incandescent lights. About 280 street arc lights were used when operated by the steam plant, also 40 private arc lights and moo to 1500 incandescent lights.

The Niagara Falls lighting station is now supplied with current to run large induction motors which have replaced the steam engines for driving the arc and incandescent lighting dynamos.

Two induction motors are used, each having a capacity of 500 horse-power, and are operated by the 2000-volt alternating current from the large generators and are giving excellent satisfaction.

The two-phase motor, No. 1, shown in illustration, is belted directly to the large alternator for supplying the incandescent lights while motor No. 2, delivering 500 horse-power, replaces the large steam engine by being belted to the main shaft, from which all of the arc machines are driven.

The problem of power distribution to small consumers is a difficult question to solve, and it is now under consideration by this company and also by the Buffalo General Electric Company and the Cataract Power & Conduit Company. Mr. Chas. R. Huntley, manager of the Buffalo General Electric Company, says the method of distribution has not as yet been decided upon, but that there are two methods under consideration. Inasmuch as there are several thousand horse-power in 500-volt motors now in operation, it would be a hardship for the consumers to throw out their motors and install alternating machines in their place. For this reason it may be decided to use 500-volt rotary transformers to supply this motor service or drive the present boo-volt power generators in the same way as illustrated above in the Niagara Falls plant, where large Tesla motors replace the steam engines.

Another method which is being considered is to use a 2000-volt alternating-power circuit throughout the city and introducing a small transformer and alternating-current motor wherever power is desired. This plan would undoubtedly be vastly more economical for outlying districts, but the power and lighting company is doing its best to lighten the burden of the consumer by making the first cost as low as possible, and still give the best of service.

THE CARBIDE OF CALCIUM PLANT.

The Carbide Manufacturing Company has just completed another large building which largely increases its plant and allows a much greater production of the carbide of calcium. On account of the great affinity the carbide has for water when acetylene gas is generated, it is necessary to ship the material in air-tight and moisture-tight metallic casks.

The original factory was a brick structure, 40 by 90 feet, and since then two other buildings have been added, one 30 by 60-feet and the other, the large one, just completed. The Carbide Manufacturing Company and the Acetylene Light, Heat & Power Company are the same interests. The two-story building is used for the crushing and grinding machinery. Into the furnace room all of the electric energy obtained from the Niagara Falls Power Company is used except that which runs the 75-hp alternating current motor at 2000 volts for power purposes. This motor operates the grinding and crushing machinery and runs at 350 revolutions per minute.

The carbide of calcium is manufactured by reducing coke and lime by means of the electric current. Coke seems to be best adapted to this work, although other forms of carbon could be used. Quicklime seems to work to better advantage than limestone or slacked lime, although either might be used.

After the coke and lime have been properly mixed and weighed, the electric furnace is charged with the mixture and the current turned on. The furnaces are of brick and contain crucibles of cast iron about three feet long, two feet wide and two feet deep. One electrode is the carbon rod in the centre, while the other electrode consists of the bed-plate. An arc is started between the carbon rod and the bed-plate, and after lengthening the arc the carbide immediately begins to be formed. After the current has been operating two or three hours the carbide is removed and the process repeated after a new charge of the mixture has been made.

The furnaces each use about 500 horse-power and have a capacity of several tons daily. The carbon rods consist of six strips about 4 feet long, 4 inches thick and somewhat less than a foot wide at the lower end, and more than a foot wide at the top. The connection is made to these rods by cast-iron clamps attached to copper rods about 4 inches square. The copper rods are joined to flexible copper cables. The current is supplied to the furnaces, which are connected in parallel, from a 1000-hp transformer, and the current is regulated when the furnaces are started by the use of a reactive coil. The General Electric Company furnished these equipments, and it is the intention to increase the capacity by introducing more furnaces and transformers, Three thousand additional horse-power has been contracted for, together with 10 new furnaces and a new building.

The Carbide Manufacturing Company of Niagara Falls is now turning out five tons of material daily, and is about to increase the present output many times. Carbide of calcium is now used largely for generating acetylene gas, for an illuminant for stereopticons. The light is very white and powerful, and equals the oxyhydrogen, accurately reproducing the subtlest shades and tints. The generators are exceedingly simple to operate and readily portable. It is certainly safer than oxyhydrogen and other artificial illuminants, and especially is this so as regards the nature of the gas itself, the quantity used and the generator.

The only materials necessary are the carbide of calcium and water. The carbide is only delivered from Niagara Falls in large metallic cases in ton lots, and is shipped to the main office, where it may be bought in small quantities. The absolute ease with which the gas is generated contrasts favorably with the time and trouble that it takes to manufacture oxyhydrogen gases for the lantern. A one-foot burner using acetylene gives more light than six five-foot burners using ordinary gas, the acetylene being equal to 125 standard candles. For use in a lantern a jet with four burners is provided equaling 500 candle-power. The carbide of calcium is a dark crystalline semi-metallic mass, and is very active in the presence of moisture in the production of this acetylene gas.

|

| Fig. 7. 500- HP Two-Phase Motor-Driving Arc-Light Machines of Niagara Falls Power Company. Fig. 8. Air-Tight Metallic Tanks for Shipment of Calcium Carbide. Fig. 9. 500- HP Two-Phase Motor in the Buffalo & Niagara Falls Electric Light Plant. |

Two pounds of the carbide is sufficient to operate four 125-cp burners for two hours. In small quantities it costs from 10 to 15 cents per pound. The carbide is placed in the generator, the stop cock is opened and as the air and gas escapes the water rises until it comes in contact with the carbide. Acetylene gas is at once generated and passing around the calcic carbide is dried and the dampness absorbed. Carbide is placed in an annular space around the holder and still further dries the gas. If more gas is generated than is used at once, the pressure of the gas forces the water away from the carbide and generation almost ceases. As the gas is used the generator descends and the operation is repeated, and so the gas is automatically generated as used. There is little doubt that carbide of calcium will be more extensively used in the near future.

CHLORATE OF POTASH WORKS.

The Chlorate of Potash Works are built upon the lands of the Niagara Falls Power Company, and a large amount of power is here used for producing chlorate of potash by electrolysis.

The Chemical Construction Company has a main building 125 feet long and 65 feet wide and two stories high. The current is transformed in another building which is 60 feet long by 40 feet wide. The company's lease calls for eight acres of land, and has at present apparatus for using 500 horse-power, with an option to increase the power to be delivered to 4000 horse-power.

The current is received as a two-phase, alternating at 2000 volts potential difference, and by means of four static transformers is reduced to a low voltage, and then by two rotary transformers the current is changed from an alternating to a direct current. Each static transformer is about 125 horse-power, while the rotaries are of 250 horse-power each. The energy delivered by the rotaries is 3000 amperes at 60 volts.

The electric equipment was installed by the Westinghouse Electric & Manufacturing Company. The current is conducted to the main building, by 3/8-inch by 5-inch copper bars, 12 in number. The distribution to the pots is made by smaller bars, 4 by 1/2 inch, in cross section. The pots are 60 in number and are porcelain lined. They are about 8 feet long and about 4 feet wide. Into these pots the chloride of potash or muriate of potash is allowed to pass from a storage tank, which has a capacity for several thousand gallons. When the chloride is decomposed into the chlorate it is transferred to the crystallizing pans. The chlorate of potash is then dried, packed and is ready for shipment.

The chlorate of potash is used largely in the United States and Europe, the consumption running into thousands of tons, the price being in large quantities 9 to 11 cents per ton. Until this plant was started nearly all the supply was imported from European countries. At present the salts for making chlorate of potash have to be imported.

THE ALUMINUM WORKS.

The next plant using Niagara power is the Pittsburg Reduction Company, which receives its current through the same feeders and subway as the chemical works. A complete description of this plant is to be found in THE ELECTRICAL WORLD of Dec. 12.

THE NIAGARA ELECTRO-CHEMICAL WORKS.

The plant next to the Aluminum Works is the Niagara Electro-Chemical Works, illustrations of which may be seen in THE ELECTRICAL WORLD of Dec. 5. The current used in this plant is received at 2000 volts, and is a two-phase alternating current, controlled by the switches and measured by the instruments shown in the illustration of the elevated platform in the Niagara Falls power house. In this plant four static transformers, each of a capacity of 125 horse-power, reduce the voltage from 2000 down to 118 volts, and after passing the switches and instruments on the switchboard the current is changed in character from an alternating two-phase current to a direct current at a potential of 116 volts. The product turned out at the Niagara Electro-Chemical Works is sodium; and another building for the enlargement of the plant is now in process of erection.

THE CARBORUNDUM WORKS.

The Carborundum Company, of which Mr. E. G. Acheson is president, and Mr. R. B. Mellon is vice-president, was one of the very first companies to use Niagara power.

The current for the manufacture of carborundum does not necessitate a change in character, as the alternating-current is used without the necessity of the use of a rotary transformer for delivering a continuous current. Mr. Acheson is the inventor of carborundum, which is a manufactured product, and is used for many purposes, the principal one being as an abrasive.

The carborundum works is the nearest plant to the Niagara power house. The current is supplied by the large 5000-hp generators shown in illustration, and is controlled from the elevated platform. The cables through the subway to the carborundum works are lead covered, operated at 2200 volts. The illustrations show a static transformer, inductor or regulator, switchboard and electric oil pump, used in the transformation of this current for use in the furnaces for making carborundum; moo horse-power is used in these furnaces. The static transformer reduces the pressure from 2200 volts to 185 volts, and it is kept cool by a continuous flow of oil which is constantly pumped through it by a small pump driven by an electric motor. The regulator is cooled in the same way. The current, after leaving the transformer, passes through the regulator, which varies the voltage as desired from 105 volts to 250 volts. When the current is first supplied to the furnace the regulator is so adjusted as to "boost" the voltage to 250 volts. After the furnace has been in operation a couple of hours and the resistance of the furnace has so decreased as to allow 3000 amperes to flow, then the regulator is used to choke down the voltage so that the power consumed shall not exceed 700 kilowatts and the current is gradually increased to 7000 amperes as the resistance of the furnace decreases until a limit is reached at which it remains nearly constant. When the current is first turned on, no change is noted in the furnace, but after an hour gases begin to come off which, when ignited, burn with a blue blaze. The whole furnace is enveloped in flames toward the end of the run, but little heat escapes, the greater part being used inside in making the necessary chemical change in the charge to produce carborundum.

The resistance of the furnace becomes constant in about four hours and remains so during the balance of the 24 hours, when the current is turned off.

The walls of the furnace are taken down; no change is observed in the outer parts of the mixture. When the current is switched off in the transformer building the flexible cables are disconnected from the bronze plates and another furnace is connected up. The mixture found after the current is switched off has become caked and can easily be pulled off, leaving bare the mass of carborundum which has been formed round the core. When this is removed crystals of carborundum of great beauty are seen. These crystals radiate in lines a foot from the centre. They are all colors; red, green, blue, yellow and violet; most of them are small, but many are large and beautiful hexagonal crystals, some even one half inch across.

The carborundum when removed from the furnace is placed in long tanks and washed with sulphuric acid. After being sifted and arranged according to fineness it is made up into wheels, hones, files, cloth knife sharpeners, etc. Carborundum is used largely in place of emery. Two tons a day are turned out now and the plant has been constructed to accommodate 4000 horse-power in apparatus.

The furnaces are of brick, about 17 feet long, 7 feet wide and 6 feet high, and a good illustration and description may be seen in THE ELECTRICAL WORLD of Oct. 26, 1895. The interior dimensions of the furnaces are 15 feet long, 6 feet wide and 5 feet high. In the centre of each end wall is a bronze plate to which tire connected the cables carrying the current and on the inner surface of the plate 6o rods of carbon are attached each 2.5 feet long and 3 inches in diameter. The charge when ready weighs about re> tons and consists of a mixture of sand, salt, coke and sawdust. When one furnace has been charged the current is turned on and another furnace is made ready while the current is doing its work. It is said a new factory will soon be built on the Canadian side of the Niagara River, where a large amount of power will be used. Crude carborundum as it comes from the furnace in natural crystals is sold in ton lots at 12 cents per pound. Carborundum grains are numbered the same as emery, the number indicating the threads per lineal inch in the sieve which they pass. Carborundum powders are graded by floating in water. The grains and powders are sold in ton lots at 15 cents per pound. The contract with the Niagara Falls Power Company was for 10,000 horse-power in such quantities and times as might be desired.

MORE NEW MANUFACTURING PLANTS.

A number of local contractors are figuring on bids for the construction of several factories to be erected on the Power Company's lands. Some of these buildings will be erected by the Cataract Construction Company.

The Albright & Wilson Electro-Chemical Company, of Oldbury, near Birmingham, England, will establish a factory on the lands of the Power Company, near the point where the Niagara Junction Railway Company's trestle crosses the Central and Erie roads and Buffalo Avenue. The factory will not require many men, but will use a large amount of power. Their establishment at Oldbury, England, has been in existence a half a century.